|

|

|

|

Locomotive Railway Carriage & Wagon Review

64 (1958)

Key page

Number 785 (January 1958)

Incorrrct Volume number (63) on page 1

The Kent Coast electrification of British Railways. 1; 5, 2

illustrations

First phase (Thanet) nearing completion. Broad details of motive power,

mainly mulltiple unis, but with some electric and diesel electric

locomotives.

English Electric locomotives for the Eastern Railway of India, 2-4.

2 illustrations, diagram, table

Class EM/2: twelve 3120 hp locomotives 3000 V dc system

Conversion of German Federal Railway 4-6-2 locomotives to oil-burning.

4-5. 2 illustrations, diagram, table

Class 01. Shortage of domestic coal, high cost of imported coal, hence

use of Bumker C grade oil. Work involved Henschel & Sohn GmbH

French-built 50-cycle electric locomotives for the U.S.S.R. 6.

35 Co-Co 5500 h.p. locomotives to work on 25 Kv: ten for express passenger

and 25 for freight working: latter including ten with regenerative braking.

Dual-frequency Austrian locomotive to be exhibited. 6.

At the Brusselss Universal Exhibition

A British Railways rail-mounted viaduct inspection unit. 7-8. 3

illustrations, diagram

Hydraulic powered booms enabled the inspection platform to lowered

beneath the wagon and structure upon it was located.

Diesel traction in East Africa. 8.

Report by General Manager of the East African Railways & Harbours

envisaged diesel traction taking over from steam. Fifteen 1800-2000

hp and eight 1100 to 1400 hp would br required for the Nairobi-Nakuru-Kisumu

section.

New Garman-built sleeping cars for international services. 9. 5

illustrations, diagram (side elevation & plan)

Hansa Waggonbau GmbH and Waggonmachinenbau GmbH built forty Class

U cars for the International Sleeping Car Co. Each car had eleven compartments

which could be arranged for one-, two- or three- berth accommodation.

Minden-Deutzz bogies were fitted.

Trials of Krauss-Maffei 2,200 h.p. Co-Co diesel hydraulic units. 10-12,

3 illustrations, 2 diagrams (including side elevation), tablle

Supplied to Yugoslav State Railways. Dynamometer car tests in Germany

between Munich and Garmitsch and Mittenwald; also in Austria on the Semmering

line and on arrival in Jugoslavia on Jugoslav Express between Ljubliana,

Zagreb and Belgrade; on the Simplon orient Express between Belgrade, Ljubliana

and Postojna, and on the Taurus Express between Zagreb and Belgrade. Tests

included the curved 1 in 40 ascent between Rijeka and Drivenik. Illustrations

include a portrait of the locomotive, it on test on the Semmering and a 2-10-2T

and a 2-10-0 hauling a freight up the Semmering.

Commonweallth Railways "roomette" cars. 13-14. 3 illlustrations,

plan

Car supplied by Wegmann & Co. of Kassel with zig-zag corridor

arrangement and another built in Australia.

New electric multiple-unit depot at Ilford, B.R. 14

Extensions to enable Ilford to service the entire Great Eastern and

London, Tilbury & Southend electric multiple unit fleets.

Renault three-car diesel units for Algeria. 15. 2 illustrations, diagram

(side elevation and plan)

Eight three car articulated units with engines within body at each

end of unit

The G.E.C. traction motor works at Dudley Port. 16

80,000 ft2; capacity fifty main line motors per week

Improved driver's brake-valve for London Transport

stock. 16-17. diagram

For caption to diagram seee page 40

Stainless steel coaches for Brazil. 17. 2 illustrations

Budd Co. for Santos-Jundiai Railway

Diesel traction for Argentina. 17-18

Until recently little has been done towards introducing diesel traction

on any scale on the Argentine Railways. The Buenos Ayres Great Southern as

early as 1930 had acquired some experimental types which were not perpetuated.

They were for shunting and suburban services and one of them, with hydraulic

transmission never ran more than 50 km These were followed by two diesel-electric

power stations, running five-car multiple-unit trains, which were then

in poor condition. Following this came three 1,700 h.p. travelling power

houses, running eight- car trains, and one similarly powered locomotive.

All were still doing yeoman service but the later units—two Arrnstrong

l-A-A-A-l and two Hariand & Wolff l-AA-AA-l— were destroyed by fire.

The only other locomotives, apart from railcars, were some little 100 h.p.

rod-driven 0-4-0 diesels with Gnrdner engine and mechanical drive.

The next move was made by the metre-gauge Central Northern Railway which,

just before becoming the General Belgrano Railway, ordered 70 Whitcomb 600

h.p. locomotives for suburban work. These were followed in 1950 by 75 General

Electric 1,000 h.p, main line diesel-electrics and in 1953 by five of 1,200

h.p. At the same time 25 G.E. 1,400 h.p, locomotives were delivered to the

Mitre (former Central Argentine) Railway and 51 Baldwins of 1,600 h.p. to

the General Roca (former B.A.G.S.) Railway. In 1955, Werkspoor delivered

fifty 600 h.p, locomotives to the San Martin (former Buenos Ayres Pacific)

Railway while the same firm a year later brought out ten 1,500 h.p. machines

to the same railway and thirty of 600 h.p. to the metre-gauge Belgrano Railway.

At the same time we have to record the only British order yet received, for

five English Electric of 1,000 h.p, The last deliveries to date are 25 General

Motors machines of 1,310 h.p. The last of these were being delivered as the

writer left Argentina, but, unfortunately, they are being put on main line

service in the winter and were not provided with steam heating boilers!

Twenty-five brake vans were now being titted with Merryweather pump boilers.

When the present Provisional Government took ever it was faced with the grave

problem of a totally deteriorated steam locomotive stock, since the foregoing

purchases had been used tu replace steam locomotives which either could not

be repaired or, for lack of spare parts, were passing through the shops at

a rare which promised delivery in some three to four years. In the meantime

Mr. Sacaggio at the Liniers works of the old Western Railway had

succeeded—in five years—in producing two super-diesel-electric

locomotives. consisting of two units each supported on four four-wheel bogies,

all motored and powered by four diesel engines of some 800 h.p, These units

cost an appalling sum, but technically were successful as they could run

on from one to four diesel engines and from two to 16 electric motors.

Unfortunately, they have been used exclusively on the Mar del Plata luxury

Budd train, of four coaches only, instead of in their legitimate sphere of

mixed-traffic operation on lines with gradients varying between I in 500

to 1 in 80.

The writer has been called in unofficially to several meetings and has always

advocated that, dieselisation should start in the shunting yard, where the

greatest savings can be made. But the present situation, with some 40 per

cent of available steam locomotives laid off, calls for an immediate replacement

of these locomotives to be able to move the next harvest. The Provisional

Government had therefore placed orders for or is in negotiation with the

Import-Export Bank about the following locomotives:-

San Martin System

25 General Electric 1,800 h.p

Mitre System

25 Montreal '(ALCO) 1,800 h.p.

Roca System

25 Alsthom (France) one 750 h.p.

Administration of Ports

15 General Electric 550 h.p. (5 ft. 6 in. gauge)

Urquiza System (former C.B.A., E.Rios, Argentine N.E. and Slate Eastern)

20 General Electric 1,200 h.p.(4 ft. 8½ in. gauge)

To be divided between San Martin, Roca, Sarmiento and Roca Systems

130 ALCO 1,800 h.p. (5 ft. 6 in. gauge)

Belgrano System

50 General Electric 1,200 h.p. (Metre gauge)

Emergencies call for immediate action, but the future, with the heterogenous

stock in existence and on order, is going to prove a major difficulty. The

committee on which the writer served recommended that for future requirements

locomotives should be built to rigid specifications in units of 600 and 1,200

h.p., duplicating when necessary for higher powers, anJ all engines to be

multiples of 600 h.p. with all details interchangeable.

It has yet to be proved that for main-line passenger and goods working in

Argentina the diesel-electric is the most economical unit in the long run.

For similar powers the diesel-electric costs three times more than a steam

locomotive and must obviously run three times the mileage. Over months of

tests it was found that a steam locomotive could run 20,000 miles a month

on a selected passenger run of 925 miles for the return trip with two hours

for servicing at the end of the single trip. But a diesel unit on the same

run could do no better as it was found impossible to fit in an immediate

return trip because of traffic and single track limitations, and in a country

like Argentina, with its single tracks and intermittent goods traffic, it

would appear that unless the running and maintenance savings are three times

the This is especially true on sections where there is still an abundance

of firewood. amortisation charges a loss will result.

Fowler 0-4-0 diresel shunter with B.U.T. 230 h.p. engine. 18.

illustration

0-4-0 diesel shunting locomotive, built by John Fowler & Co. (Leeds)

Ltd., had been undergoing tests and demonstrations at Fowler's testing site

near Leeds. The engine specified for this prototype was the B.U.T. 926 cu,

in. direct-injection diesel engine. The locomotive could haul trains of up

to 720 tons on level track. It had an initial tractive effort of 15,000 lb.

at 3½ m.p.h, and a top track speed of 14½ m.p.h. Power units of

this type are already operated by British Railways and had been chosen to

power the 24 twin-engined railcars shortly to be shipped to the Indian Railways

from Australia under the Colombo Plan. The engine for the Fowler locomotive

had been specially derated to 176 b.h.p. at 1,500 r.p.m. Transmission from

the engine is through a 20 in. traction type fluid coupling and a Hardy Spicer

transmission shaft to a four-speed Self-Changing Gears epicyclic gearbox.

A further shaft and. bevel pinion co.ects the main gear- box to the forward

and reverse gearbox, which is of Fowler manufacture. Final drive is taken

by a jackshaft from the gearbox to coupling rods and so to the wheels.

The "Unionmelt" boxcar rebuilding tecnique of Seaboard Airline R.R., U.S.A.

18-19. 3 illustrations

Welding

New diesel depot at Crewe, B.R. 19-20. 3 illustrations, diagram

Atlas wheel turning machine Iikely to be used for tyre profiling on

multiple units as well as locomotives, and also for carrying out such work

for other neighbouring Motive Power Districts where the provision of an

additional machine is not justified.

News of the month. 20

Engineering company may take over Dundalk Works. 20

To produce even a quarter of the material which Ireland imports from

foreign engineering works would require thousands of Irish workers, according

to Frank· Aiken, Irish Minister for External Affairs, who recently outlined

the Governrnent's plans for the proposed Dundalk Enginering Works. The new

company has followed on the closing of sections of railways in Nurthern Ireland,

and the cutting off from the Dundalk railway works of all rail servicing

work, except what is necessary on the 50-mile section of the Great Northern

Railway from Dublin to the border between the Republic of Ireland and Northern

Ireland. The Government considered the alternatives of reducing the servicing

staff at Dundalk to the number required for the 50-mile section concerned,

or extending the facilities at Dundalk into a large national engineering

works. Aiken said that there were tens of millions worth of equipment coming

into Ireland every year made abroad by men with the same skills as those

who had been employed until now on railway work in Ireland. There were also

railway extension programmes in other countries te which rolling stock could

be sold if produced at a competitive price. He added that the Dundalk Engineering

Company would take over, free from capital liability, the premises and equipment

of the old railway works, and would have available hundreds of highly skilled

workers,

N.S.W.G.R. electrification. 20. illustration

The western main line of the New South Wales Government Railways was

now electrified as far as Lithgow. The route west of Penrith traverses the

Blue Mountains and has long sections of 1 in 33 gradients. Originally the

line included the celebrated zigzags near Lithgow, long superseded by an

ordinary deviation with many tunnels. Considerable accelerations have been

made, particularly of freight trains. The Commonwealth Engineering Co. Ltd.,

Australia, was expecting to complete in December its contract for 40 motor

and 40 trailer coaches for this line. With the delivery of this stock all

passenger traffic on this section .will be handled by eight-coach multiple-unit

trains, comprising two first class and two second class motor coaches and

four second class trailers. The electric locomotives which have been used

since the service began an 22 June 1957t will be freed for other purposes,

The multiple-unit stock is of stainless steel, the first use of this construction

on a large scale in Australia.

B.T.C. order Drewry Equipments for diesel shunting locomotives. 20

The British Transport Commission announced that 42 sets of engine

transmission and control equipments for 0-6-0 diesel mechanical shunting

locomotives of 200 h.p. had been ordered from the Drewry Car Company. The

completed locomotives will be allocated between the North Eastern and Southern

Regions.

Tulloch Ltd. to use German diesel engines. 20

The New South Wales manufacturing firm of Tulloch Limited' has concluded

an agreement with Mercedes-Benz and Fried. Krupp by which ir has the sole

use of Mercedes-Benz diesel engines and Krupp hydraulic transmission for

rail traction in Australia.

Letters. 20

Pierre Weil.

As perhaps one of its oldest readers (since 1897), may I congratulate

the Locomotive Magazine on its recent development into its present form,

which greatly enhances its status as a serious technical journal. In years

gone by it fulfilled a real want as a recorder of steam locomotive development

and news for popular consumption, and wias a source of great joy to the younger

generation interested in such matters, amongst whom I was a devoted enthusiast.

I well remember the eager anticipation in the 1890s with which I awaited

the next issue (price 2d!). Now, however, with the tremendous strides made

in electric (and diesel) traction since the War, the beloved magazine of

my schooldays has become a technical journal in the true sense.

To watch the departure of an 800-ton high-speed express (or rather rapide)

from the Gare de Lyon in Paris, headed by an ultra-modern 80-ton Bo-Bo or

120- ton Co-Co (or even by an already obsolescent 2-D-2) electric: locomotive,

is as thrilling an experience as that afforded by a train headed by the finest

and largest modern steam locomotive. An electric locomotive is no longer

just a motorised truck; it is a highly complicated machine with as much diversity

and personality instilled into it by its creators as the steam locomotive

always had, and still has. But it is a far more complicated and subtle

personality, and the Locomotive Magazine in its wisdom has realised this

and has risen nobly to the occasion. This does not signify that it has abandoned

our dear old and faithful friend, the beneficent and beloved steam locomotive.

It still gives us all necessary news regarding it in its old age, but in

the nature of things, the electric (and diesel) traction matters will necessarily

take top place more and more.

Number 786 (February 1958)

The manning of diesel and electric units on British Railways. 21

Double-manning agreement between BTC and ASLEF and NUR to convey second

man on runs longer than 100 miles, in hours of darkness (midnight and 06.00

and so on W.P. Allen called it a "victoory for commonsense".

[BR class 9F 2-10-0 No. 92178]. G.W. Morrison. 21

Fitted witth double chimney when built at Swindon

Dual-purpose diesel-hydraulic raicars for the Ulster Transport

Authority. 22-4. 3 illustrations, diagram

James Courtney design for express services between Belfast and

Londonderry/Derry or for limited freight haulage over same route. British

United Traction Leyland six-cylinder engines mounted on Metalastik shear

mounts with Self-Changing Gears Ltd Schneider torque converters manufactured

under licence.

Photographs of CIE K3 2-6-0 as modified to burn turf (T.K. Widd) and Bulleid

0-6-6-0 turf burner at Inchicore Works. 24

See also Volume 63 page 219

Dual frequency electric locomotive for French Railways. 25-6

Bo Bo capable of working on woorking on Swiss Railways at 15 kV and

French system at 25 kV

Diesel locomotive experience in the United States.

26-8. illustration

Precis: No other country in the world has so wide an experience of

diesel locomotive manufacture, operation and maintenance as the United States;

in no other country, indeed, has there been so revolutionary a change of

motive power in so short a time. In 1935 U.S.A. railways owned 42,000 steam

locomotives and 150 diesels; twenty years later the figures had become 6,000

and 24,700 respectively, and the diesels were handling 90 per cent of the

traffic, which itself was 50 per cent heavier than in 1935. By then some

£1,200 million had been invested by the railways in diesel power, but

this change had made possible an annual reduction of fully £100 million

in operating expenses.

Net ton-miles of freight trains per day had risen from 13,000 to 26,000 ;

average freight train speed had gone up from 16.4 to 19.0 m.p.h., all operating

stops included; and the average daily mileage of freight locomotives from

110 to 150. Over the 20 years, while the total locomotive stock, steam and

diesel, was falling by an average of 1,100 units annually, the diesel fleet

was growing by an average of 875 units each year, and this reduced number

was showing itself capable of handling a steadily increasing flow of traffic.

These striking facts formed the introduction to a paper read on December

18 last before the Institution of Locomotive

Engineers Paper 582 by H.G. McClean Export Manager of the Electro-Motive

Division, of General Motors Corporation, Chicago. If his paper showed some

slight bias in favour of railway dieselisation, this is hardly to be wondered

at, seeing that the foresight and enterprise of his own firm, more than any

other single factor, have been responsible for bringing about this revolution,

and that Electro-Motive has built 65 per cent, and still is building by far

the major proportion, of the diesel-electric locomotives at work on American

railways to-day.

The rapidity of this diesel development on United States railways has been

due in large measure to their acceptance, almost from the start, of the

manufacturers' standard locomo- tive designs. This acoeptance has made it

possible to streamline production and thereby to reduce the capital cost

of the motive power, while at the same time cutting down the stock of spare

parts necessary and reducing maintenance costs generally. In the Electro-Motive

designs, for example, the V -type diesel engine first introduced in 1938,

whether the six-, eight-, 12-, or 16-cylinder model, still retains the same

basic cylinder dimensions and continues to have completely interchangeable

pistons, liners, cylinder heads and valves.

By developing and improving these standard constituents it has been possible,

without any increase in cost, to double the life of the parts and at the

same time to increase engine out- put by 50 per cent. In conjunction with

the same range of diesel engines built into locomotives, now number- ing

some 20,000 in all, only two standard types of electric generator ·

and a single traction motor design have been used throughout; there has also

been a high degree of standardisa- non of bogies, wheels, axles, axle boxes

and brake equipment. The manufac- turers' slogan" twice the work at half

the cost", as compared with steam traction, has thus largely been realised.

The course followed by railway dieselisation in the D.S.A., Mr. McClean

continued, has been, first its application to shunting, then to passenger

services, and finally to main line freight operation. Economy in shunting

and marshalling was obvious with locomotives which could work around the

clock if necessary, and soon was found to be on such a scale that these economies

alone could pay the cost of a diesel shunter in two years. The first application

in passenger working was with high speed long- distance trains, such as those

making continuous 40-hr. runs over distances of 2,200 to 2,300 miles between

Chicago and the Pacific coast, with layovers up to 10 hr. at each terminal,

where again the continuous avail- ability of diesel power could be put to

maximum use.

But the real test of diesel economy in main line operation came in the second

stage, with the dieselisation of complete divisions, or of certain types

of service en bloc, in which the costly diesel units no longer monopolised

the cream of the operating assignments, and had also to provide stand-by-

power. For this stage between 300 and 40 separate detailed work studies were

made, in which the manufac- turers co-operated with the railways, before

final decisions were reached. Precise running times could be calcu- lated

and guaranteed by the manufac- turers, in working out the cycles of operation

and the number of units nee d e d ; previous experience supplied all the

information required as to unit operating costs.

By the time the third stage was reached, of 50 to 80 per cent diesel- isation,

the railways themselves had accumulated sufficient information to forecast

all the economies that could be effected by further substitution of diesel

power for steam. The present and final stage is an intensive study as to

how the existing diesel stock can be put to the maximum possible use before

the decision is reached as to how many additional units will be needed to

complete the diese1isation. On a number of the leading railways, of course,

this final stage has been attained already.

American diesel-electric units for passenger service are mostly of the AlA

- AlA type, from 2,000 to 2,400 h.p.; for freight of the B - B type, from

1,500 to 1,750 h.p.; and for shunting and general purpose duties also of

the B - B type, from 1,000 to 1,200 h.p., though there may be variations

from these stan- dards for special reasons. If automatic train control is

in use, the passenger diesels travel at up to 100 m.p.h. on certain main

lines, and 90 m.p.h. on others; typical freight diesels operate at speeds

up to 65 m.p.h., and normally maintain speeds up to 50 m.p.h. on the level

and 10 to 12 m.p.h. up 1 in 50 gradients. A modern freight train will be

worked by a triple-unit locomotive of 4,500 to 5,250 h.p., permanently coupled,

the middle or "B" unit being a hooster unit without driving cab, and the

two other "A" units.having driving cabs at the outer ends only. Many passenger

trains are operated by two A units coupled.

Some 75 per cent of the total American demand recently, however, has been

for general purpose or mixed traffic designs, which have a single driving

cab near one end of the unit, and good visibility along both sides of the

6 ft. wide hoods which house the engine-generator sets. These hoods have

deep side doors which facilitate inspection and maintenance. The body styles

involve a basic difference in body construction; with the narrow-hood diesels

the strength of construction is almost entirely in the underframe, with its

deep-section longitudinals, whereas in the streamline passenger and freight

locomotives, with their light underframes, of shallow depth, the strength

is in the deep girder members which extend for the length and depth of the

side-walls.

As the first American road diesels were for high-speed passenger service,

their bogies were designed accordingly, and this fact has affected all subsequent

bogie development. The AlA type passenger diesels have 36 in. wheels, 14

ft. 1 in. wheelbase, and a one-piece cast frame and bolster. Their equipment

includes roller-bearing axle boxes, 6½ in. x 12 in., which use parallel

rollers mounted on a sleeve; the whole is arranged to permit lateral movement

of the box, und with spring control (at first by leaf springs but later by

moulded rubber springs) providing for lateral movement which at first is

almost free but rapidly comes under restraint. Equalisers are provided between

adjacent ax1eboxes, with dual nests of coil springs between fheir upper sides

and the underside of the bogie frame. Four long outside swing hangers out-

side the bogie frame support two spring planks carrying four sets of fully

elliptic springs, on the top of which rests an H-shaped bolster with large

diameter centre-plate; the latter carries all the weight.

The freight and general purpose locomotive bogie is of the two-axle type

with 40 in. wheels, 9 ft. wheel-base, and a centre-plate 37 in. above rail.

As with the passenger bogie, the roller box is 6½ in. x 12 in., but

no equalisers are provided; double nests of coil springs are fitted between

the axle boxes and the one-piece cast bogie frames. Outside swing hangers

27½ in: long on 7 ft. 6 in. centres support the spring plank, which

carries two sets of elliptic springs to the bolster and a large-diameter

centre-plate. In the opinion of McClean these bogies have outstanding merit

in design and operation, though their development — especially in the

matter of the long outside swing hangers — has been possible only because

of the generous limits of the American loading gauge. In weight, the passenger

diesels average 100 lb. per h.p., and the freight diesels 135 lb. per h.p.

Initially, American permanent way engineers did not favour any greater

axle-loading with diesels than the maxima previously authorised for steam

power; the even torque and absence of hammer-blow with traction motors, as

opposed to reciprocating motion, has latterly permitted a relaxation to the

extent of 25 per cent, and diesel axle-loads on this increased scale are

now coming into general use. Mr. McClean considered, however, that then:

had been undue concentration by track engineers on the effect on track of

vertical loading, and too little on lateral effects, and that more attention

might well be paid to bogie construction and to lateral flexibility at' the

axleboxes in order to reduce track wear-and-tear. The general maximum

axle-loading now permitted for diesels in the U.S.A. is 60,000 lb. (27 tons)

on wheels of from 36 to 40 in. diameter.

In height, a maximum of 15 fr. above rail along the locomotive centre- line,

and 13 ft. 6 in. at the eaves level, is generally available, except over

the tunnelled railway approaches to New York that have overhead electric

equipment. With wheels up to 40 in. diameter, these limits allow generous

engine-room dimensions up to le ft. high and 10 ft. wide, affording ample

space for the installation of a V -type engine with the radiator above. In

length, most diesel locomotive units measure about 50 to 55 ft., with the

diesel-generator set occupying about 35 per cent of this total. Bogie centres

are located about 30 ft. apart, so that fuel tanks (and water tanks also,

if the unit carries a steam-heating boiler) can be accommodated below the

main frames between the bogies — a suitable position both for refuelling

and for even distribution of weight. The diesel unit underframes are designed

to withstand from 800,000 to 1,000,000 lb. (360 to 445 tons) maximum push

or pull — an important feature now that four-unit freight locomotives

frequently haul loads well in excess of 100 bogie wagons, that is, upwards

of a 5,000 tons loaded, over certain routes. Couplers are of the central

automatic type, and also are designed to withstand a maximum tension or

compression up to ],000,000 lb. (445 tons).

American locomotive ratings in general are conservative; with a 1,750 h.p.

freight unit, for example, the gross engine h.p. output is 1,910, and 16-cylinder

engines of this type have operated on continuous load for 100 hr. at up to

2,200 h.p. The aim is to assign the locomotive a rating which will ensure

reliable operation in all conditions, and yet be sufficiently high to enable

it to compete in hauling capacity with locomotives of other makes. There

are few countries in which more extreme operating conditions are met with

than in the United States. Diesel locomotives may have to' work in extremes

of ambient temperatures ranging from 30°F below zero to 120°F above.

Moreover, on through north to south runs the same locomotives may travel

from an area of heavy snow to one of arid desert in a single journey, or

vice versa. Through the Rocky Mountains several of the most important main

lines operate over summits ranging from 7,000 ft. to over 10,000 ft. in altitude.

Fuel conditions also may vary considerably on one through run; diesels working

through between Chicago and the Pacific Coast, for example, may refuel up

to four times en route with fuels of differing characteristics.

Of the four types of diesel engine, from all the different manufacturers,

now in general use in the U.S.A., the two which predominate are of the V-type,

and the other two are in line engines; the two most in use also are of the

two-stroke type, the other two being four-stroke. Cylinder dimensions range

from 8ý in. x 10 in. to 9 in. x 12 in., and engine speeds from S35

to 1,000 r.p.m. An advantage of the two-stroke V-type engine is accessibility

of the "top deck", either within the 10 ft. wide body of the streamline designs,

or through the side doors of the hood in the general purpose units. An even

greater advantage is the ease with which the condition of pistons, rings

and liners can be inspected through the ports in the liners. The engine radiator

system embodies a.c. electrically-driven fans, individually controlled by

thermostats, which ensure correlation of the temperatures of the engine,

cooling water and lubricating oil. Elaborate measures are taken also to ensure

the best possible filtration of fuel oil, lubricating oil, and air intake.

In the United States, diesel locomotives — as distinct from railcars

— have for the past twenty years been built exclusively with electrical

transmissions. As measured from the engine input at the generator to the

output of the traction motors at the wheels, transmission efficiency at full

load averaging 82 per oent can be relied on from one-fifth to maximum locomotive

speed, and a peak efficiency up to 84t per cent. Auto- matic load controls

are universal, the equipment, according to the notch used by the driver on

his controller, automatically adjusting the generator voltage and current

to ensure maxi- mum efficiency of transmission over the widest possible range

of operation without permitting either overheating or stalling of the engine.

Forced draught ventilation with filtered air is used for generators and traction

motors.

With the weight and speed of American trains, high capacity air-brakes are

essential. Each locomotive unit is equipped with a three-cylinder two-stage

compressor, air-cooled or water-cooled, working at from 275 to 835 r.p.m.;

at the full speed the displacement is 235 cu. ft. per min. The normal equipment

of an AlA-AlA type passenger diesel comprises 18 in. shoes with clasp brakes

on all wheels, and four 11 in. compressed air cylinders on each bogie.

Dynamic braking, first applied on locomotives working over long continuous

gradients, such as those through the Rockies, has since become so popular

as to have been installed on 40 per cent of the diesel locomotive stock.

On long and winding descents, the fact that dynamic brakes can hold heavy

trains at the specified maximum speed without any use of the air brakes has

effected very considerable savings in the wear and tear of brake blocks and

brake rigging, as well as in the avoidance of overheating of wheel tyres.

The use of dynamic braking now has spread to railways with relatively level

main lines also, particularly on locomotives operating fast and heavy freight

services, on which this type of braking does away to a considerable degree

with the use of air brakes.

The remainder of Mr. McClean's paper was devoted mainly to statistical'

comparisons which bear out the claims made in the first two para- graphs

of this review, showing how completely justified has been the revolutionary

changeover in the United States from steam to diesel power; they emphasise

also the remarkable fact that improved design and building techniques have

kept the price of diesel horsepower stationary, if not, indeed, on a slightly

falling scale during a period when there has been an increasing rise in the

cost of labour and materials. This is an achievement of which American

manufacturers may well be proud.

The effect of capital cuts on British Railways. 28

Although there is still no word from the B,T.C. as to the items of

the modernisation programme postponed because of the Government-imposed cuts

in capital expenditure, some answers given in Parliament at the end of the

year, although bare of detail, confirm that their effect on British Railways

will be by no means negligible. Electrification was not mentioned, supporting

our belief that the major projects proposed in the original plan, which are

advancing to schedule, are unaffected, but some other departments in which

the Minister of Transport & Civil Aviation has disclosed cuts of capital

expenditure are vital to the success of the modernisation plan, The most

serious is the enforced slowing down of the programme for the fitting of

freight stock with continuous brakes, for it is in freight operations that

re-equipmerit is most urgently necessary if the railways are to survive.

The Minister has also confirmed that future plans for diesel locomotives

have had to be reduced, and has revealed that there have been cuts in schemes

for new rolling stock, which presumably includes diesel multiple-units, It

is difficult to make much of the figures that are being mentioned to support

the Government view that the cuts stipulated are small, because of rises

in prices since the modernisation plan was announced, with the result that

the total of £1,240 million it was estimated to cost in 1955 has now

risen to around £1,500 million, As we go to press an officer of the

Southern Region at Exeter has disclosed that the a.c. electrification of

his Region's western Section main lines has been postponed because of the

capital cuts. .

An electrogyro locomotive for the National Coal Board. 29.

illustration

Oerlikon electrical equipment in locomotive built by Sentinels

(Shrewsbury) Ltd

A motorcar transporter for Anglo-Continental service. 30.

illustration

M.A.T. Transport Ltd two-tier vehicle built by Newton, Chambers &

Co. Ltd. of Sheffield. Prototype running between British Motor Corporation

at Oxford (Cowley) and Cologne via Harwich to Zeebrugge train

ferry.

New rolling stock for Boston Rapid Transit. 30-1. 2 illustrations

Pullman Standard Car Manufacturing Co. supplied 25 two-car sets of

welded all-steel construction with air bellow suspension to the Metropolitan

Transit Authority of Boston

Diesel services in Edinburgh District. 31

Inaugurated 3 February to Corstorphine and North Berwick. Later

to Galashields via Peebles, Rosewell, the southern loop via Morningside

Road and the Leith North branch.

The end of steam construction in Czechoslovakia. 32; 33

Skoda ceased to manufacture steam locomotives: photographs and leading

dimensions of 2-10-0 with Krauss-Helmholz truck and claimed to be most economical

freight locomotives in Europe and three-cylinder 4-8-2 and 4-8-4T passenger

classes. Alll were fitted with Kylchap double chimneys and smoke deflector

plates.

Prototype second class open coacch for B.R. by Birmingham R.C. & W.

Co. 32; 34. 2 illustrations

Sir Hugh Casson advised on interior design with foam rubber seating

for 39 second class passengers.

New lightweight rolling stock for the Ghana Raileway by Cravens.

34; 35. 7 illustrations, plan

Five car trains of welded steel construction with buffet cars anbd

rounded observation cars at rear.

G.E.C. transport contracts. 34; 36

General Electric Co. somewhat garbled text relating to North British

Locomotive Co. 3,300 h.p. Bo Bo presumably electric locomotives for LMR

electrification and to 1000 h.p. engines for diesel melectric Pullman trains

and to equipment for electric multiple units

Conversion of Stratford repair shop, B.R., for diesel working. 36-7.

illustration

Original structure completed just prior to WW1. A diesel engine section

for stripping, cleaning and overhauling diesel engines, with fabricated beds

TO accommodate any of the six different types of power units as well as

degreasing tanks, Parawash equipment, Colosyl bath and jib cranes over the

engine beds. The electrical section repairs main and auxiliary generators,

traction motors and control gear. A d.c. supply from a motor generator will

supply power for testing control gear and traction motors. This section also

contains battery charging sets and portable machine tools. Heavy repairs

to diesel shunting locomotives will also continue to be carried out in a

portion of this bay.

The heating system uses radiant heat created by water under high pressure

fed by an automatic oil fired boiler of the wet back double-pass type. Such

a system gives complete freedom of functional use of the entire shop floor

space, keeps down the movement of dust and makes for maximum economy in the

use of fuel.

News of the month. 37-

B.R. safety in 1956. 37

In view of the tragic collision at St. Johns, Southern Region, on

4 December 1958 and its inevitable publicity it is salutary to have the reminder

of The Chief Inspecting Officer's report to the Ministry of Transport &

Civil Aviation for 1956 that not a single passenger was killed in a train

accident proper on British Railways that year, despite an increase of 2.2

per cent m the number of passenger journeys and of 3.2 per cent in

passenger-miles over 1955. There was also a decrease in the total number

of casualties, but an increase of 6.1 per cent from 1,156 to 1,226: the total

number of train accidents of all kinds reported; in these three railway servants

and 15 other persons lost their lives, 13 of the latter being occupants of

road vehicles involved in level crossing collisions. In his review of the

year, the Chief Inspecting Officer comments that the number of accidents

directly caused by want of care or irregularities in working by operating

staff has been steadily increasing since 1950. The 1956 figure was nearly

24 per cent higher than that for 1950, and train crews were responsible for

most of (he increase; the number of accidents caused by them has practically

doubled since 1950, with a proportion of enginemen's to guard's mistakes

of about six to one. On the other hand, it is encouraging to note a steady

post-war decline in the number of accidents resulting from disobedience to

signals, with the result that a large proportion of the mishaps due to failure

of the human element have been minor, but the tendency of the latter to increase

is a disturbing trend to which the B.T.C. is giving careful attention. There

has also been a decline since 1951 in the number of accidents caused by technical

defects, from 15.1 to 10.1 per cent of the total for 1956.

Miniature buffets in B.R. coaches. 37. illustration

A new type of light refreshment service, a miniature buffet built

into an ordinary second class passenger coach, had been developed by British

Transport Catering Services for use on services for which a special catering

vehicle cannot be provided and to augment or replace existing restaurant

car services. The first of twelve vehicles being so equipped was introduced

on The Flying Scotsman on 13 January to augment the regular restaurant

car services on this train. As more second class vehicles are converted to

include the buffets they will be introduced on other Eastern Region services

between Liverpool Street and Cambridge, March, St Ives (Hunts. bet eating

prohibited on guided bus!) and Norwich.

London Transport new railway rolling stock. 37

London Transport order 248 cars for the Metropolitan Line, at a cost

er over £5 million to operate to Watford, and, when electrification

is extended beyond Rickrnansworth, to Amersham and Chesham. All seats in

facing pairs on each side of a central gangway. The seats to have higher

backs, those on one side of the gangway accommodating space for two passengers

and those on the other for three passengers. The cars will have air-worked

sliding doors and ample standing room so that they can handle heavy in-town

traffic on the tunnel sections between Finchley Road and Aldgate. Each train

will consist of four driving motor and four trailer cars. There will be rhree

pairs of double sliding doors on each side of the trailer cars and two double

sliding doors and one single for passengers as well as the motorman's door

on each side of the driving motor cars, The stock will have lightweight unpainted

aluminium alloy bodies, rubber suspension for smooth running and economical

maintenance, and fluorescent lighting. Replacing electric and steam-hauled

compartment-type coaches, it will give an improved service to all stations

on the outer part of the Metropolitan Line, with all eight-car trains instead

of the present mixed six-car and eight-car services. Passengers travelling

beyond Harrow-an-the Hill will have four more trains an hour in the morning

and evening peak periods. Delivery will be timed to begin with the

electrification of the Metropolitan Line between Rickmansworth and Amersham,

and Chesharn, and the four-tracking of the present double-track section between

Harrow-on-the-Hill and Rickmansworth, which are planned to be completed in

1961.

In the rush hour all Circle Line trains are to be increased from five to

six cars by adding to the District Line stock thirteen R stock cars of the

latest type which arc now on order. With the rearrangement of certain existing

trains and the conversion of some cars at Acton Works, it will then be possible

to transfer some cars from the District Line to lengthen the Circle Line

trains. This wil! also enable R stock to be used for the Olympia service.

Two prototype tube trains on trial on the Piccadilly Line were equipped with

under-floor motors giving one-seventh more passenger accommodation than the

present Piccadilly and Central Line trains. They have "silver" aluminium

body panelling with rubber suspension and fluorescent lighting. If they prove

successful in service, the design will be adopted as the basis for replacement

orders for the whole of the Piccadiliy Line and Central Line rolling

stock.

London Midland Region diesel success. 37-8

More than one-and-a-quarter million passengers a month were travelling

in lightweight diesel trains operated by the London Midland Region —

317,000 more a month than were carried by the same services in 1956, when

some were still operated by steam locomotives. But even where the diesels

had been running for more than a year, there is still an upward trend in

passenger service carryings. The ten lightweight diesel unit services on

the London Midland and their carryings in a recent month compared with the

same period of 1956 were:-

| 1956 | 1957 | |

| West Cumberlansd Area (whole scheme introduced by 7 February 7 1955) | 144,585 |

140,710 |

| Watford-St. Albans (introduced 25 July 1955) | 37,877 |

35,095 |

| Bury-Bacup (introduced 6 June 1956) | 101,614 |

92,688 |

| Birmingham-Lichfield (introduced 5 March 1956) | 275,508 |

159,603 |

| North Wales Area (introduced 28 May 1956) | 104,133 |

83,902 |

| Banbury- Buckingham (introduced 13 August 1956) | 6,423 |

2,693 |

| Manchester-Buxton/ Macclesfield (introduced 8 October 1956) | 316,400 |

186,858 |

| Manchester-Hayfield/ Maccles field (introduced 17 June 1957) | 198,303 |

136,768 |

| Harrow & Wealdstone-Belmont (introduced 6 August 1957) | 889 |

397 |

| Crewe-Stoke-Derby (introduced 16 September 1957) | 84,249 |

60,154 |

These figures detail only trips beginning and ending within the areas served by the diesels and not those of which the trains were used for part of a journey, hence the low figure for the Belmont branch, which takes no ,account of passengers continuing north or south of Harrow on the main line. The L.M.R. announced in mid-December that 1958 would see extensions of the Manchester and Birmingham area schemes and the introduction of new diesel railcar workings between Liverpool Central and Gateacre and Liverpool Central and Warrington (from 6 January, at hourly intervals and using Gloucester C. & W. Co. units); between Derby and Nottingham; and in the Leicester area. Railbuses are to be tried on the Northampton- Blisworth, Bedford-Northampton and Bedford-Hitchin branches. New diesel railcar depots are in prospect for Allerton, Nottingham, Newton Heath, Nuneaton and Reddish. The Region expected to have 72 main line diesel locomotives at work by the end of this year.

Craven-built coaches on thr S.R. 38-9

The prototype coaches by Cravens, described in our August-September

1957 issue, are making the round the country. At the end of November they

were working on the L.M.R., running in the 14.30 p.m. Euston-Liverpool and

the 14.10 p.m. back, and were then moved to the Southern Region. From December

3-5 and 9-12 the two cars, Nos. E3082 and E4638, were incorporated in the

stock cf the 10.30 Waterloo-Bournemouth West and the 17.00 back, after which

they were due .to move in turn to the Western (for work from January 6-17),

the E. & N.E. Regions and, ultimately to Scotland. We learn that most

passengers using the cars have been much impressed. In December the Southern

Recion was also trying out two of the ether prototypes, Doncaster-devised

open second h No. M3721 (an existing coach converted) and Metro-Cammell corridor

second No. M25455; these cars were running in the 09.40 Brighton-Bournemouth

and l3.50 back from December 2-5 and in the 17.00 WaterJoo-Exeter and 07.30

back from December 9-13, after which they too were expected to gc to other

Regions. The Metro-Cammell car was on the 07.25 Wolverhampton-Paddington

from December 16 for several days and at least one Cravens car was seen in

the 14.10 Paddingtcn-Birkenhead on January 1.

Last British Atlantic No. 32424 Beachy Head passing Chelsea on 24

August 1957. S.C. Nash, photographer 39. illustration

On 12.35 Leicester to Hastings on West London line

Swindon to build more diesel-hydraulic locomotives. 39.

Swindon Works to build 30 main line 2,000 h.p, diesel-hydraulic

locomotives for use in the W'estern Region, additional to the three locomotives

of the same type at present under construction there. This order is a further

step in the programme for the complete change over to diesel traction of

all Western. Region services west of Newton Abbot, and of many of the through

services between Paddington, Bristol and the West of England. Of the 130

diesel-hydraulic locomotives required for this programme, replacing over

200 steam locomotives only 34 locomotives, also of 2000 h.p. remained to

be ordered. The 30 locomotives to be built at Swindon would undertake the

heaviest passenger and freight working between London and the West of England.

They will have Maybach diesel engines and Mekydro transmissions; and will

be of the BB wheel arrangement. The locomotives will be classified as Type

4 in the British Railways classification of diesel locomotives, and will

be numbered D.803-D.832. Contracts for the power equipments have been placed

with Brush Traction Ltd. (for the supply of the Maybach diesel engines) and

with J. Stone & Co. (Deptford) Ltd. (for the Mekydro transmissions).

The electric control equipments had been ordered from British Brown Boveri

Ltd .. London. The three 2,000 h.p. Maybach-Mekhydro locornotives nearing

completion at Swindon are now to be mounted en four-wheeled bogies, and will

not be AlA-AlA as previously announced.

A dual-purpose wagon. 39. 2 illustrations

MacGregor-Comarain. French open wagon capable of being covered by

a roof

New Metropolitan Vickerrs locomotives for National Coal Board. 39

Metropolitan-Vickers Electrical Co. Ltd. has supplied many battery

locomotives to collieries of the National Coal Board, and orders had

been for collieries in the Scottish Division. The first of these was for

two 14-ton flame-proof battery locomotives for use at Rothes colliery; these

had been commissioned and two more locomotives ordered for the same colliery.

Six locomotives of the same type were also on order for Bilston Glen collierv.

These locomotives had cabs at both ends and employ a triple combination control,

which is economical in its demands on the battery. In operation the two halves

of the 200 V 420-Ah battery are first connected in parallel while the two

motors are in series; the battery halves are then connected in series with

the motors still in series, and finally the motors are connected in parallel.

In each of these combinations field weakening gives an additional intermediate

running notch. The whole scheme enables shunting and starting operations

to be carried out with the least possible waste of battery power in the starting

resistors.

Alco shipments to Argentina. 39-40

Alco Products, Inc. begun delivery of 130 new all-purpose export diesel

locomotives to the Argentine Railways. Sixteen of the six-motor, 1800-h.p.

DL- 540 road-switcher locomotives were shipped in January. The DL-540 is

an export version of Alco's widely used domestic road-switchers, the four-motor

DL-701 and the six-motor DL-702, introduced two years ago. Of the Argentine

order, 30 locomotives to be placed in service on the D.F. Sarmiento railway,

55 will go to the General Mitre and 45 to the General San Martin. The locomotive

ir:corporates wide gauge bogies identical to those on the Alco World locomotive.

It provides for an electric car-heating system to be installed to adapt the

locomotive for passenger service. The equipment includes compressed air brakes

for the locomotive and vacuum brakes for the train. The DL-540 is powered

by the Alco 12-cylinder, V-type, Model 251, turbo-charged diesel engine,

the power unit which is standard in one of three sizes on all Alco locomotives.

In designing the locomotive, Alco used a standard DL-701 frame and fitted

six General Electric Model 761 traction motors. The units in the Argentine

order develop 40,200 lb. continuous traction at 13 rn.p.h. and have a maximum

speed of 75 m.p.h. They are equipped for multiple-unit operation. The locomotive

has a maximum height of 14 ft. 8 in.

C.I.E. diesel hydraulic shunting locomotives with Maybach 400 h.p. engines. 40. illustration

Improved driver's brake-valve for London Transport

stock. 40.

Caption for diagram on page 16

Stone-Faiveley pantographs ordered by B.T.C.

40

See also Issue 780: bulk

oorders for electric multiple units on Scottish, London Midland and Eastern

Regions

Fish vans with roller bearing axleboxes. 40

Existing fish vans being fitted with Timken roller bearings for North

East Scotland: 12.30 Aberdeen to London express fish train: converted vans

being identified with a Blue Spot.

Diesel orders and deliveries. 40

Commonwealth Engineering Co. Ltd, Australia order for six Budd-type

stainless steel railcars for Malayan Railway with Rolls Royce 230 h.p. engines.

International General Electric Co. of America supplying 45 1200 h.p. diesel

electric locomotives to South African Railways.

C.I.E. Post Office vans. 40

Inchicore four-wheel and bigie TPO vehicles

Book reviews. 40

The Electrical Year Book, 1958. Emmett & Co.

The Mechanical World Year Book, 1958. Emmett & Co.

Number 787 (March 1958)

Meeting current steam locomotivbe demands. 41-3.

3 illustrations

Comment on the greatly accelerated schedules introduced on the Midland

Division of the London Midland Region from June 1957. Noted that time could

be kept with Class 5, notably No. 44985 which ran from Leicester to St. Pancras

in ten minutes less than the new scedules. Trains sometimes ran late on the

Nottingham route even with double heading. Greater availability of Class

7 locomotives would have helped: further Jubilee class should have been rebuilt

or rebuilt West Country Pacifics could have been employed.

British Railways "Warship" class diesel-hydraulic locomotives. 43-5. 3

illustrations, diagram (side elevation)

North British Locomotive Company A1A-A1A with MAN engines and Voith

transmissionjs. A demonstration run from Paddington behind No. 600 Active

achieved 94 mile/h down Dauntsey bank, but was followed by the faiure

of one of the engines and motoring back on one engine.

U.S. railroads store diesel power. 45

270 diesel engines had been placed in store by Class 1 railroads.

The Union Pacific was taking deliveryof fifteen 8500 h.p. gas turbine electric

locomotives from General Electric. Railroads still using steam power were

noted.

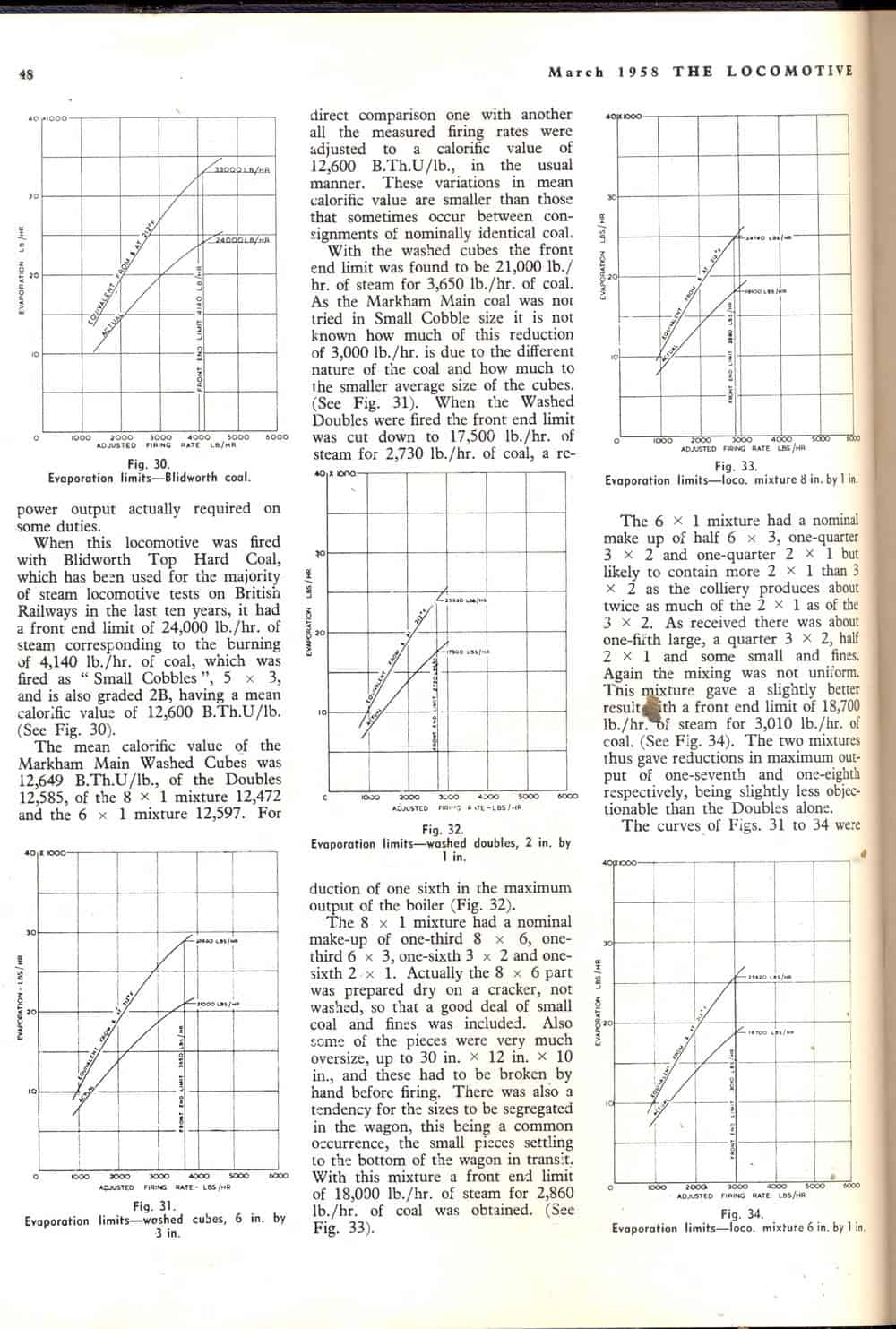

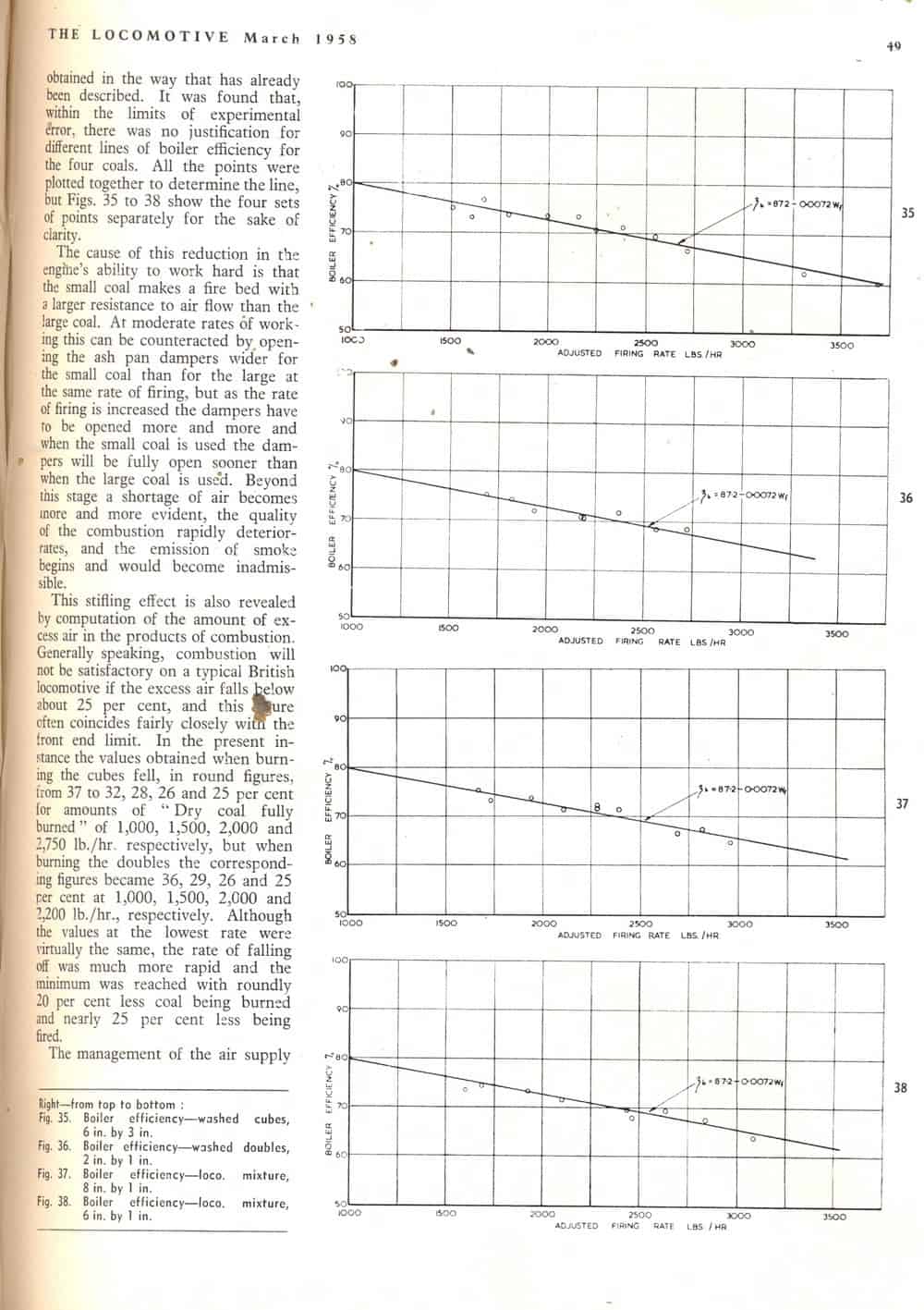

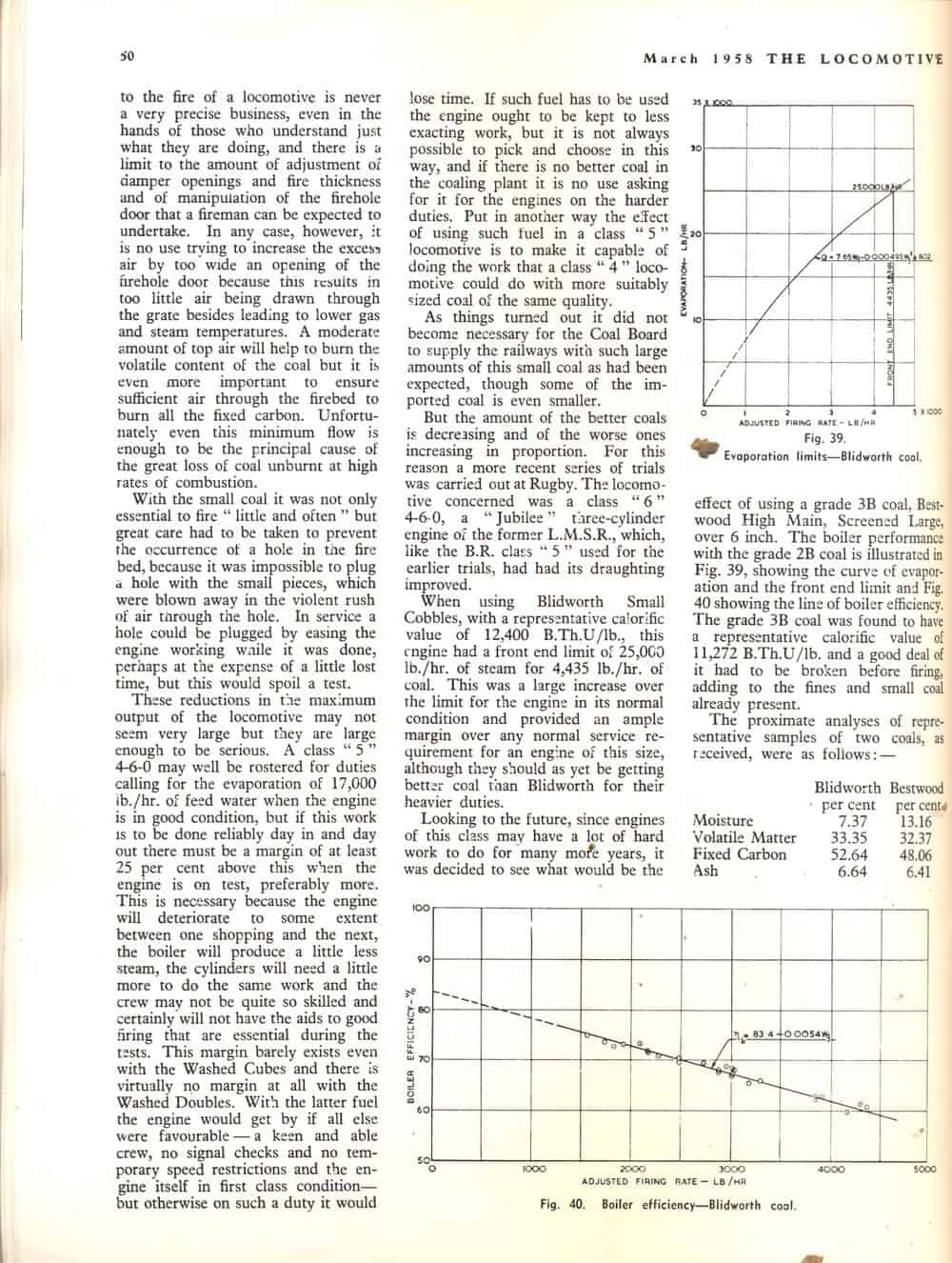

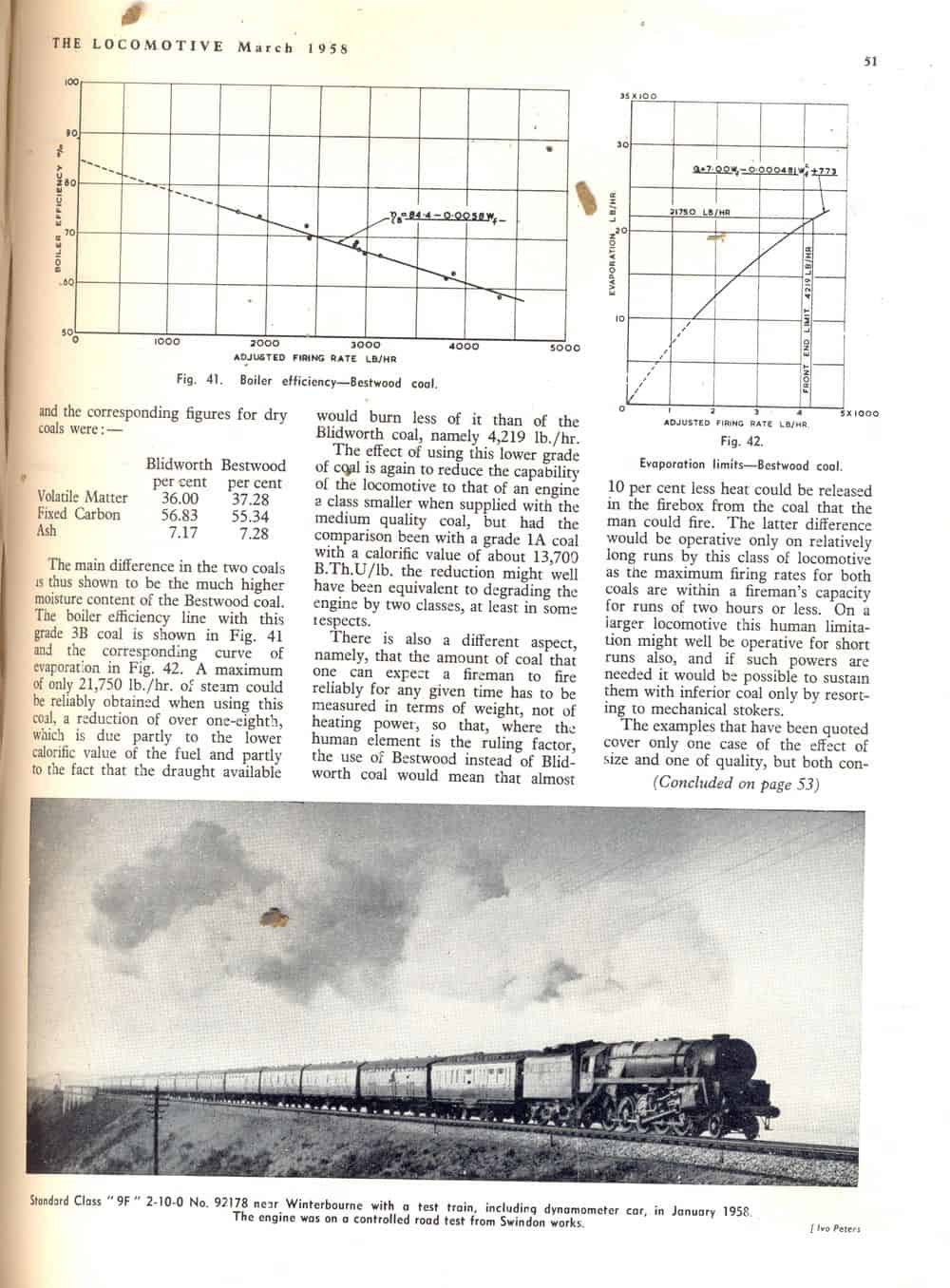

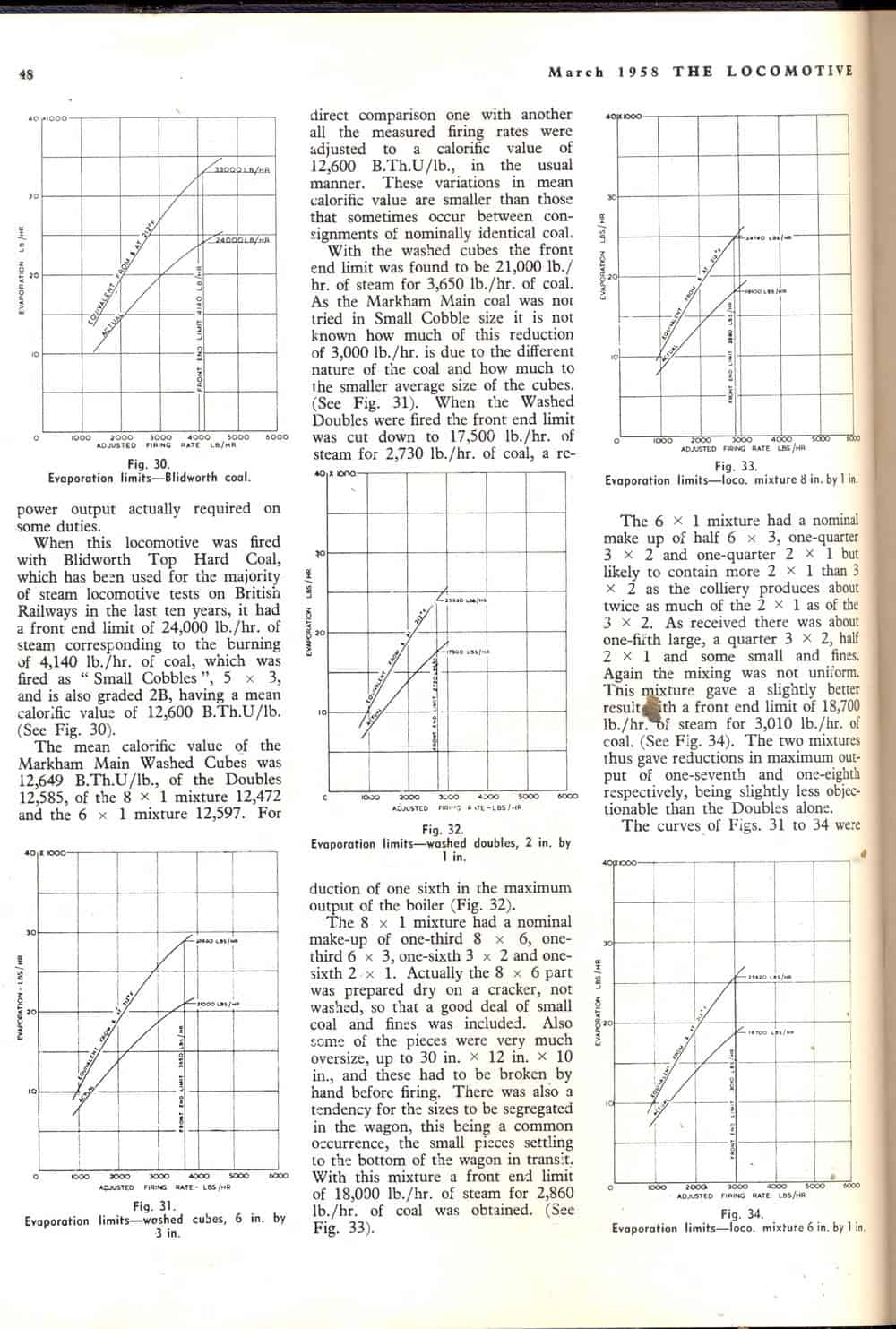

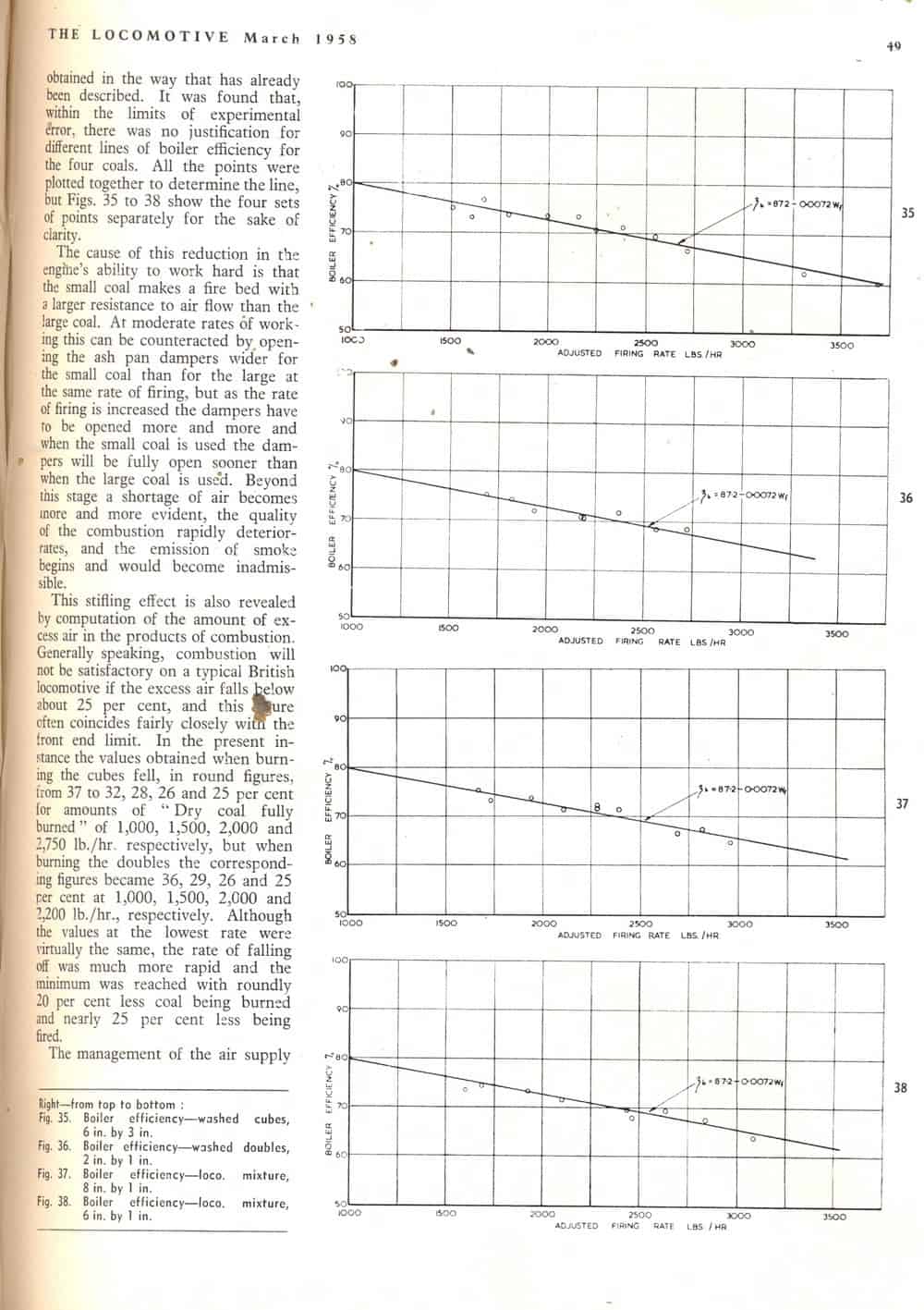

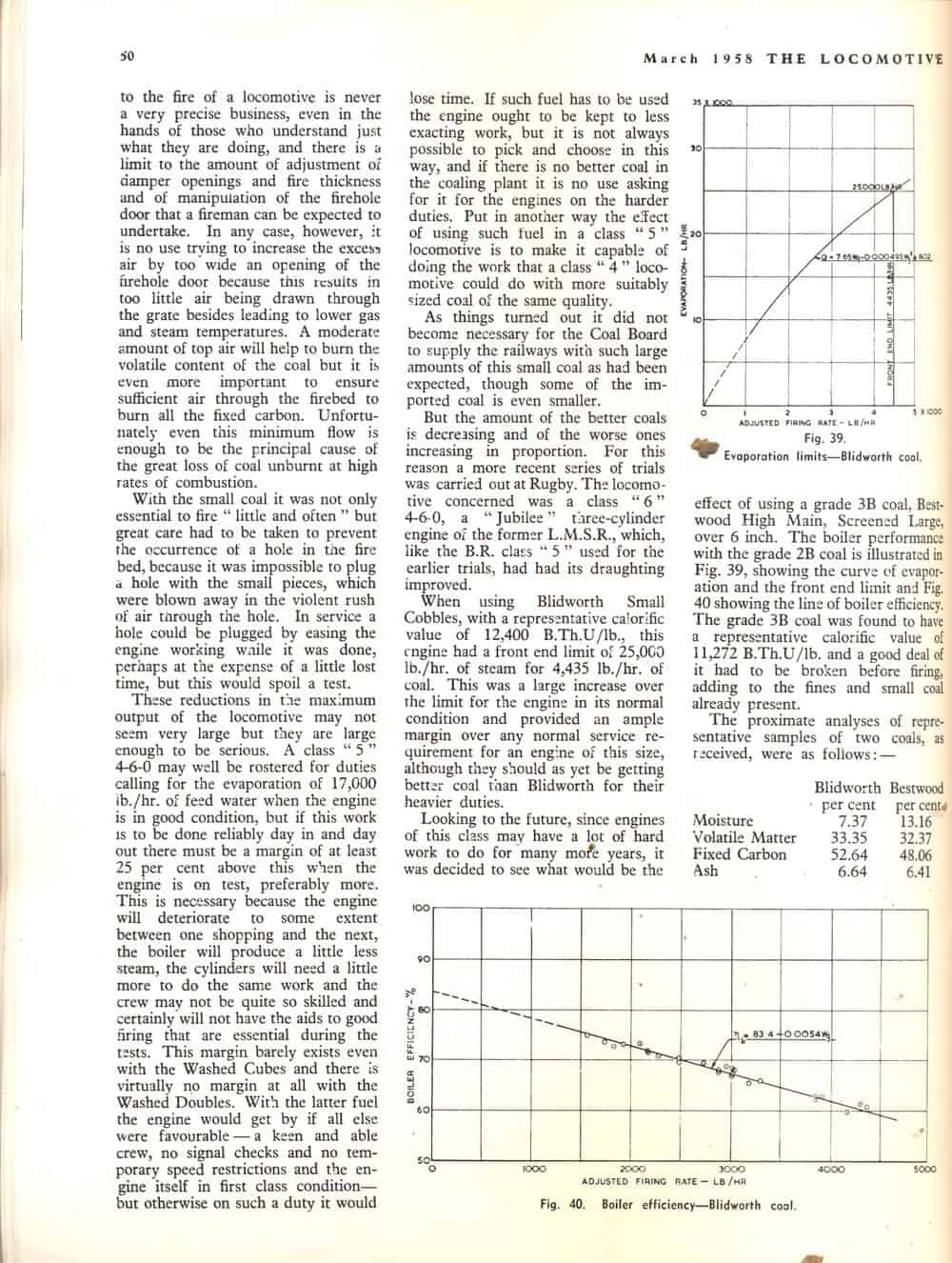

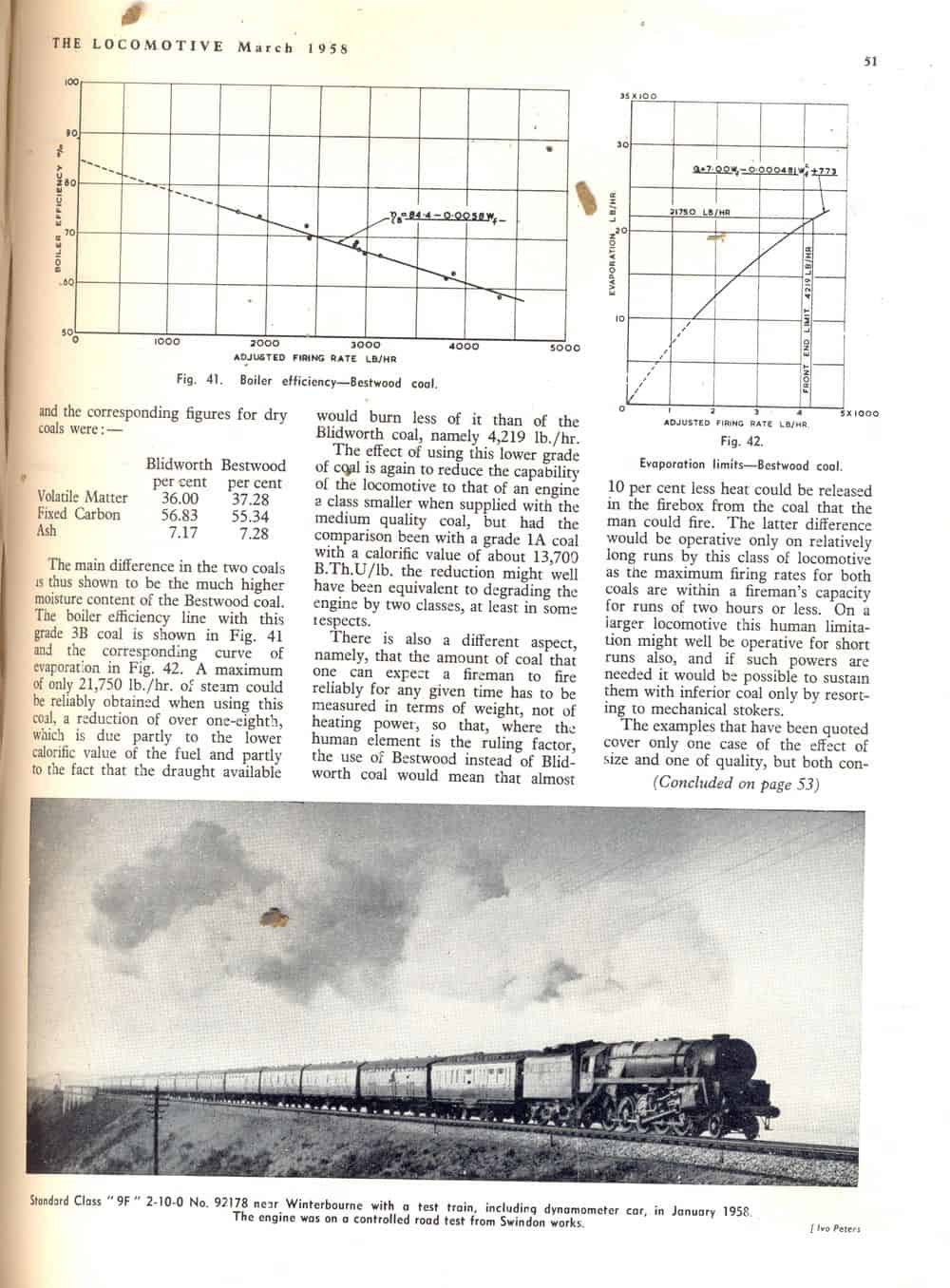

Locomotive testing at Rugby, B.R.: the quality of coal.

46-51; 53. 2 illustrations, 13 diagrams

From Locomotive Performance and Efficiency Test Bulletin. One advantage

of the steam engine over other types of prime mover is that it can tolerate

a wide variation in the nature of the fuel used without damage to itself

and with relatively little effect on its efficiency. This is a valuable feature

of the steam locomotive, which moves from place to place and receives its

fuel supplies from a number of different sources.

Even within the confines of Great Britain there are over 1,000 sorts and

sizes of coal liable to be supplied to the railways for locomotive use, besides

imported coal, opencast and patent fuel, but it is a little under one- third

of this total that is regularly supplied at present and some 90 per cent

of the tonnage is covered by about 250 sorts and sizes. In some areas several

collieries may work neighbouring parts of the same coal seams so that these

varieties will differ relatively little one from another and, in any case,

even the coal from one seam of one pit varies a little in quality as mining

proceeds. Even allowing for such grouping, however, the total number of kinds

and sizes is still very large. The quality varies from some of the best

locomotive coal in the world to coal which is not really suit- able for the

purpose at all. Coals of many qualities have been used by the railways for

a century or so, but, in general, for most of this period there has been

an ample supply of good coal available. This is no longer so, for the amount

of good locomotive coal mined is decreasing steadily year by year.

Because of the ready availability of , good coal in the past the great majority

of British locomotives were designed to burn such coal, even if its precise

nature and quality did vary to some extent. Although a steam locomotive'

can be designed to burn very low grade fuel effectively, it may not be easy

to burn coal of a quality much lower than that for which a particular locomotive

was designed, without an appreciable loss of performance. Wide as the toleration

of fuel quality may be it has its limits, and those limits are now being

reached in some cases and will be reached in many more before the steam

locomotive ceases to be an important factor in the motive power of British

Railways.

Two questions arise from this situation: how much are the locomotives really

affected and what can be done to restore them to their former state of

usefulness? It is first necessary to determine how the nature of the coal

does affect the performance of the locomotive. There are several quite distinct

effects but all result in one way or another in putting a limitation on the

power output of the locomotive. With any given kind of coal each locomotive

will have an upper limit to the amount of steam that it can produce, and

use, per hour.

If the draught available were strong enough, increasing with the rate of

steaming, it would be possible to in- crease the rates of firing and steaming

until the " grate limit" was reached. If stili more coal were fired and the

draught increased, the result would be the production of less steam instead

of more. The reason for this is found in the falling boiler efficiency and

the consequent parabolic shape of the curve of evaporation against firing

rate. The grate limit corresponds to the vertex of the parabola. This fall

in boiler efficiency is due almost entirely to coal being lost un- burnt.

As the draught gets stronger and stronger more and more coal is carried away

before it can be burned and eventually this loss becomes so large that it

has the effect mentioned. This phenomenon is only rarely met with, however,

because in most cases the draught available is not strong enough and a "front

end limit" is reached at a lower steaming rate than that corresponding to

the grate limit. 'I he available draught can no longer draw sufficient air

through the ashpan, grate and firebed and products of .combustion through

the boiler tubes, for a balance to be maintained between supply and demand.

Whereas the grate limit can be precisely .defined from the equation of the

boiler efficiency line, there is no absolute definition of the front end

limit, the determination of which involves a certain amount of judgment by

the testing staff, but it may be said that it is an estimate of the highest

steaming rate that can be reliably repeated without failing to satisfy the

normal standards of acceptability of the tests. The firing rate at which

such a limit is reached with any given kind of locomotive must depend on

the nature of the fuel, especially in hand-fired coal-burning locomotives,

in which a large part of the resistance to flow of air is due to the

firebed'Itseli. The resistance to air flow througb the firebed will depend

on the natun of the bed and on its thickness, both functions of the nature

of the coal. Is the coal one that cokes, sticking to- gether when heated,

or does it burst into small fragments? Does it swell or not? Does the ash

melt at the temperature of the firebed and form clinkers or does it accumulate

as powder? How large are the pieces of coal that are fired? All these questions

are involved.

Much of the problem cannot be dealt with by testing on a test plant but some

aspects can be So treated and some examples follow. One reason why the railways

cannot obtain the coal that they would like to have is that other users compete

for the same grades, and another is that the coal mined may be of the wrong

size, or that the preparation plant at the colliery may no longer be adequate

to prepare the coal in the desired way due to different methods at the coal

face or in underground transport One consequence of changes in min- ing methods

and of the exhaustion I)f some seams of coal is that more and more coal is

raised in the smaller sizes and less and less in the larger ones, It is generally

accepted that an ideal size of lump for use on a hand-fired locomotive is

a four-inch cube but pieces anything from half to double this size, say

three-inch to five-inch cubes, are good. Appreciably larger lumps will not

make a reasonably even firebed and smaller ones tend to cause a variety rof

troubles. In practice the lumps are of different sizes, but the variation

in size may be limited in 3 graded coal or almost unlimited in un-graded

coal or "run of mine" as it is termed in America. Even graded coal contains

some fines which result from handling and transport, especially in the case

of very soft coals. A few years ago it seemed probable that the Coal Board,

would have to supply a considerable tonnage of rail- way coal in much smaller

sizes than had hitherto been usual. It was known that the use of such small

coal was deleterious to the performance of the locomotives on which it would

be used but there was no information on how harmful it would be. A series

of tests were conducted at Rugby to investigate this matter. At the same

time it had been suggested that the pernicious effect of small coal might

br mitigateg byy mixing it with ssome large coal and tests were arranged

to include two mixtures as well as small coal alone and large coal to set

the standard.

The size of coal is usually described by name or by the use of two figures,

which are dimensions in inches. These are not dimensions as understood on

an engineering drawing. The first dimension is the size of mesh of the screen

through which the coal has passed and the second is the size of screen over

which it has passed without falling through. The same name is apt to be used

by different pits for various dimensions. Two sizes that have been found

very suitable for hand firing are 5 x 3 and 6 x 3, but the proportion of

larger and smaller pieces varies considerably. The size it was proposed to

supply was 2 x 1, Washed Doubles and two mixtures, one 8 x 1 and one 6 x

l, with different proportions of sizes. Pieces with one dimension larger

than the first figure can pass through the screens and pieces smaller in

some or all dimensions than the lower figure can be carried over the screens

; and there is some degrading of the 'coal in subsequent handling and transport.

Facilities for providing these various sizes were available at Markham Main

Colliery, near Doncaster, the coal concerned, from the Barnsley seam, being

graded 2B by British Railways wnen supplied as Washed Cubes,6 x 3.

The railway grading of' coals is as follows:-

lA Coal which is suitable for through runs up to 300 miles.

1B Not so good as lA but can be used when that is not available.

2A Coal which is suitable for through runs up to 150 miles.

2B Not so good as 2A but can be used when that is not available.

3A & 3B Coal suitable for shunting and trip working. A is better than

B.

U "Unwanted" coaL

The practice of mixing coals of different kinds, which is adopted on a

considerable scale by some Continental railways, is not used in Britain and

no facilities are available to make such mixtures. The term mixture as now

used refers to a mixture of coai sizes, not of different types of coal.

The locomotive available at Rugby at the time was a B.R. Standard Class 5

4-6-0, which had had its draughting improved as described in the supplement

to Bulletin No. 6.

Whilst there might be other effects the one expected to be most troublesome

from the railway operating point of view was a reduction in the front end

limit of the locomotive, since this would put a limit to the power that the

locomotive could be relied upon to produce in service, lower than hitherto

and possibly lower than the power output normally required on such

duties.

A Jubilee class 4-6-0 with improved draughting was also tested.

|

|

|

|

LOCOMOTIVE TESTING (Concluded from page 51) cern locomotives that steamed well. When the figures quoted at the outset are recalled, the magnitude of the problem will be realised and it will be plain that there is no possibility of subjecting all varieties of coal to systematic tests. Thus, reliance must continue to be placed mainly on the observation of behaviour in service and the judgment of the inspectors concerned. On the other hand it would appear that locornotives that do not steam well are liable to be affected more severely by inferior coal quality than those that do steam well, and in any case even a very small deterioration in the capability of a doubtful performer may be enough to render such a locomotive almost useless for its intended purpose. It is here that tests can play both a direct and an indirect part in helping to deal with the situation and :1 future article will deal with some of the work that has been done with the object of improving the steaming of certain locomotive classes,

Experience with steel fireboxes on the Southern Region,

B.R. 52-3

Precis of ILocoE Paper 584

Among the many departures from traditional locomotive practice

introduced with varying success in 1941 by O.V.S. Bulleid in his first Southern

Railway Merchant Navy Class Pacifies were the first all-welded steel boilers.

Experiments had been made in this country in the use of steel in place of

copper for fireboxes, but never before had welding replaced riveting. The

reason given by Bulleid for this change was that with the high working pressure

of 280 lb. per sq. in. which he proposed to use copper firebox plates might

have inadequate strength; there would also be the risk of wasting away of

stay-bolt heads, and of pitting of the steel tubes by electrolytic action.

Moreover, suitable steels were now available for firebox use, and steel also

would be free from the creep to which copper is subject.

On 12 February 1958 a paper was read before the Institution of Locomotive

Engineers by M.G. Burrows and A.L. Wallace reviewing the successful experience

of the Southern with these fireboxes which, it is interesting to note, have

been retained in the rebuilt versions of these engines whereas other less

satisfactory features, such as the chain-driven valve-motion, have been

abandoned. While these boilers at first were a considerable preoccupation

to those responsible for their maintenance, improved methods of' welding

'and avoidance of too rapid cooling off of the boilers cured the initial

cracking troubles, while the somewhat disturbing corrosion was almost completely

eliminated by applying the French T.I.A. (Traitement Integrale Armand) treatment

to the boiler feed water.

The paper dealt first with the welding methods developed at Eastleigh Works.

The material used in the firebox fabrication is a mild steel containing 0.15

per cent carbon and not exceeding 0.55 per cent manganese and 0.03 per cent

sulphur and phosphorus; a tensile strength of 24-28 tons per sq. in. is called

for, with an elongation of not less than 25 per cent in 8 in. As the result

of experience, a "make-and-break " technique was evolved in the butt-welding.

The plates are brought together with their edges forming an angle of 70°,

and with a nominal gap of 1/8 in. at the root of the "V".

An 8 gauge electrode is used, and is moved in a semi-circular arc from one

side of the "V" to the other, when the arc is broken; the process is then

repeated in the reverse direction, forming a bridge of metal. The bridge

is gradually built upwards at a rate of some 60 strikes per min. until the

root run is complete. The slag is then removed by taking a very light chip

with a broad-nosed chisel, after which a second run is taken along the length

of the "V" ; the latter, however, is a straight and not a make-and-break

run. For the third run the progressive down-hand method is used, but with

a No. 6 electrode.

The channel foundation ring is fabricated from separate pressings for the

sides, ends and corners, and in view of its importance as the link between

the inner and outer fireboxes and the number of welds involved, all the latter

are subjected to full X-ray examination with each firebox. The firebox is

held in a specially designed manipulator for welding, so that the down-hand

position may be used throughout. The biggest problems were those posed by

the necessity to control the shrinkage rate at the joints and to ensure correct

alignment of the plates, and, as the paper remarks, "blood and sweat", if

not actual " tears", were expended in the boiler shop at Eastleigh before

a reliable technique for all the operations was evolved.

All the firebox stays are of the direct type except for a ring of flexible

stays round the diaphragm plate at the lower end of esch of the two thermic

syphons with which each firebox is fitted. As the result of experience, monel

metal was substituted for the previous acid open hearth steel used at first

for certain of the water-space direct stays in the zones in which breaking

is most frequently experienced. The water- space stays are screwed in and

caulked at the outer ends and riveted over on the fire side, while the crown

stays are riveted over at both ends. At the firebox tube-plate the tubes

are expanded and beaded, and the joint is completed with a sealing weld round

the periphery of each bend. In order to reduce local stresses in the tube-plate

during the welding of the tube beads, steam is used to bring the boiler

temperature up to about 200°F., and a predetermined sequence is followed

in the welding operations. The paper goes in detail into all the procedure

both of fabrication and also of subsequent radiographic examination.

Since the introduction of these welded fireboxes, the main troubles which

have been experienced and overcome have been divided into two groups, first,

cracking, and, at a later date, corrosion. In the earliest days fractures

varying in length from tin. to 3 in., and generally radiating from stay holes,

began to develop, the greatest concentration being below the necks of the

thermic syphons. Occasionally, staff carrying out repairs inside the fireboxes

were alarmed by loud reports, caused by the sudden development of fractures

up to 20 in. long and opening out to 1/16 in. wide. To a lesser

degree similar cracks were found in the back-plate, concentrated chiefly

below the firehole door.

Careful investigation established that the cause was a too sudden and uneven

cooling down of the fireboxes prior to washing out or repairs, leaving high

residual stresses. A system was then evolved to ensure a more gradual cooling,

and this has completely eliminated the large cracks and reduced the small

ones to a minimum. Partial failures of the welds between the syphon necks

and the pockets in the throat-plate were brought to an end by the same means.

It may be noted that when the earlier groups of Merchant Navy fireboxes became

due for renewal, the syphons were found to be in a condition good enough

for re-use as they stood, though the increased present life of these fireboxes

will level up this difference in future.

After the first of the light or West Country Pacifies had been in service

for a year, a defect peculiar to this class was discovered ; it was the

development of horizontal fissures in the foundation ring corners, on the

water side of the inner leg of the channel section, and chiefly at the back

corners. Careful investigation showed this to be a combined resul: of erosion

and corrosion, probably due to the rapid circulation of unsatisfactorily

treated boiler water. An immediate remedy was found by welding a

1/8 in. layer of stainless steel as a corrosion-resisting

material to the corners affected, and then stress-relieving them. These measures

were taken with a few boilers only, however, for shortly after this the 'decision

was reached, as mentioned earlier, to apply the French T.I.A. treatment of

feed water to all the Bulleid Pacifies.

Up to 1946 it was suspected that corrosion was developing in some of the

welded steel boilers, being made evident by leaking stays all round the fireboxes

in the fire area and various other signs. But in that year it became a matter

of greater conncern when bulging was discovered in the side wrapper plate

of one of the first ten Merchant Navy Pacifies. Investigation showed that

extensive corrosion had taken place on the water side, to such an extent,

indeed, as in part to reduce the thickness of the plate from the original

3/8 in. to ¼ in. The boiler in question had been in service for just

over four years and had run 169,000 miles. The firebox was then taken out,

and was found to have suffered extensive corrosion, particularly at the back

end of the crown-plate and on either side of and between the syphons. In

no case had any of the welded seams been attacked, and so far as the syphons

were concerned, it was present only in the part of the flanges forming the

rear end of the crown-plate. Physical and metallurgical examination proved

that there was nothing in the manufacture or composition of the steel to

account for the defect and it was clear that if these steel fireboxes were

to prove reliable in service, some comprehensive system of feed water treatment

was essential. Until then the only such treatment that had been used on the

then Southern Railway was by introducing soda-tannin briquettes into tender

tanks, and into the boilers of all locomotives after washing out. Such treatment

was somewhat haphazard in its application, however, except west of Exeter,

where softer water was in use, and briquettes were fed systematically to

the water supply by means of a by-pass feeder.

In these circumstances the decision was reached to experiment with the French

T.I.A. system of water treatment. Five new West Country Pacifies working

between Victoria and Ramsgate were fitted in 1947, and the results achieved

in the elimination of scale and reduction of boiler corrosion were so promising

that it was then decided to equip in the same way all the engines of both

the Merchant Navy and West Country classes without further delay. Already

the life of these boilers, which previously averaged about seven years, has

been extended to twelve years, and may well continue for some time longer.

Recently a new method of internal water treatment, known as tube feeding,

has been devised, and has been applied with considerable success to six West

Country Pacifies that had not up till then required the boiler renewal which

would have been accompanied by the fitting of the T.I.A." equipment. As the

tube feeding equipment has been proved to equal the T.I.A. method in its

effectiveness, and is cheaper to fit and maintain than the latter, it is

likely to supplant the T.I.A. treatment in future.