|

Journal Institution of Locomotive Engineers

Volume 25 (1935)

| Steamindex home page Updated 2017-12-03 | Key file | The IMechE virtual library is accessible (full papers, all diagrams, photographs, extensive tables, etc).available via SAGE |

Journal No. 123

Sedgfield, J.R. (Paper 333).

Machine tooling methods and machine shop re-organisation. 1-84. Disc. 84-110.

[Part 2] 112-60. Disc.: 160-72.

Presented at the Perez workshops Central Argentine Railway on Friday

23 March 1934 chaired by J.G. Mayne.The Paper was built round the work of

these shops and this includes the illustrations and a folding plan of the

layout of the Works.

There were seven specialised locomotive machine shop sections where the machines

were grouped together to perform certain ranges of work:

Wheel Section.

Axlebox Section

Crosshead Section

Rod Section

Motion Work Section

Brake Gear Section

Boiler Stay Production Section.

As most of the more interesting and important locomotive machining operations

were performed in these sections, they were dealt with in some detail, section

by section. The remainder of the machine shop can also be divided up conveniently

into four separate sections:

Fabrication Section.

Brass Shop.

Tool Room.

General Section.

The specialised brake gear section and the general section do not offer any

points of particular interest, and they will therefore be dealt with last

of all and in as abbreviated a manner as possible.

Presentation of thr Alfred Roslin Bennett Award to C.A.

Cardew. 169-72. illus.

Correspondence between H.A. Harrison, Secretary of the Institution

with H. Young CME of the New South Wales Government Railways in 1934 concerning

the Award to C.A. Cardew for his paper Some observations on the practice

of providing lead with the piston or slide valves of modern locomotives

(Paper No. 306) in Volume 23.

Journal No. 124 (March-April 1935)

The Institution's Annual Dinner 1st March 1935.

175-81

Guests, attendance list and speeches:

see report in Locomotive Mag.,

1935, 41, 94.

Sanders, T.H. (Paper No. 334)

The evolution of railway vehicle suspension. 183-211. Discussion.: 211-17.

Paper presented at the Third Ordinary General Meeting at the Institution

of Mechanical Engineers on Thursday 29 November 1934 at 18.00: Charles Williams

(Past-President) in the Chair.

History of suspension systems for both locomotives and rolling stock from

the very earliest days through to "contemporary practice" on the Michelin

and Bugatti railcars, and in the several types of resilient wheel then available.

Rubber is considered as a spring material and is mentioned in both a historical

context and in contemporary applications. The effect of permanent way is

considered, although incorporating rubber into that is not mentioned.

Discussion: W.F. McDermid (211-12)

experience was on a railway where the locomotives were rather notorious

for their easy riding, the explanation being that they were carried on laminated

springs with a minimum deflection of about about five-sixteenths of an inch

per ton and also they had auxilary rubber pads underneath, with the result

that the engines ride very smoothly. During the course of my expenence, however,

I had to ride on an engine that came from another dlstnct. We were not familiar

with that type of engine, and It was my misfortune to make a trip on the

footplate; my teeth chattered because she rode so badly. The explanation

being !hat the springs were very stubborn. After consultation with my chief,

he decided to put thinner. spnng plates in. That meant, of course, that the

stress In the spnng material was higher than before, but the deflection per

ton was greater, the alteration certainly reduced the trouble. I think I

am right in saying that, after having supported the load of the vehicle,

the real function of the spring is to absorb movement due to the inequalities

of the track, With the least dlsturbance to the load. The springs must do

that to keep the vehicle on the road, and I think that the solutlon for rough

riding troubles, which I have just mentioned, would be the correct one in

most cases, in that a much greater deflection for a given load involves less

disturbance for a given amount of movement. I should like the Author to give

us his views on that matter. .

H. Holcroft: (212) The Author has treated springs

and their relation to the track rather from the point of view of easy riding

and the absorption of shocks, but it is very essential to have good springing

for safety in running. It is Important that there should be as little disturbance

as possible of the loads distributed on the different wheels, in order .that

there shall be no derailment at any point; if there is a momentary loss of

load on a wheel, there will always be a tendency for the flange to climb

whilst under a side thrust, and, of course, once a flange climbs up it is

almost certain to lead to a derailment. We must not lose sight of the fact

that springing is primarily for safetv purposes rather than ease of running,

however desirable that may be. I do not think the Author mentioned the diamond

frame bogie, in which the axleboxes are fixed and the frame itself acts more

or less as a spring, because it is made in such a way that it is fairly flexible.

F. Rogers:(212-13) The Author gave some figures in regard

to the resilience of spnngs, from 300 inch-lbs. per lb. for laminated springs

to 820 for helical springs, and I would ask whether they included the weight

of the essential fittings concerned, as well as the springs. Necessarily

in application the fittings may be of different welght according to the general

design of the springing and suspension, and perhaps he would enlighten them

as to the over-all reduciion of weight which might be attained. No one was

more alive than the Author to that and to all other aspects of springs and

suspensions.

One sometimes heard the opinion expressed by a limited number of experienced

people, and more particularly in reference to tramway rather than railway

rolling stock, that the design of the axle was a factor of great Importance

in reference to the elasticity, or springing, or suspension, In a broad sense,

of the vehicle. That might appear somewhat puzzling, since the elastic deflection

of an a was only a small amount. However, what was deflecting was not the

axle only, but the axle plus the wheels, all.the way round from one point

of contact of wheel with rail to the other. If that deflection under load

were observed, either by calculation or trial, it would be found to be very

much more considerable than by loading the axle alone on a pair of V-blocks.

Some engineers were of opiruon that, on account of greater resilience, double

tapered axles, with reduced diameter at the middle, were less liable to breakage

than straight axles of equal maximum diameter. They all realised that the

elasticity of the system as a whole had to be taken into account, and a previous

speaker had suggested that even the elasticity of the frame was not a negligible

factor.

P W. Bollen (213): It would be interesting to

have the views of the Author on the relative merits of laminated springs

and spiral or volute springs for driving boxes and for bogie boxes. In certain

cases where bogies have been fitted entirely with cylindrical spiral spnngs

they have been reported as riding roughly, and I believe that in some cases

derailment has been put down to the use of these spnngs.

H.I. Andrews (213-14): In discussing the subject

of the evolution of railway vehicle suspension, there is one point which

has been omitted by the Author from reasons. of modesty, and which I feel

should be included. In the design of electric rolling stock, the space available

for the suspension gear is frequently extremely limited, and in a recent

instance where there was very little space available, the Author was set

a very difficult problem. After making a comparison of various types of springs

available, he put forward a Belleville washer spring which .he had adapted

for railway purposes and which I believe is the first time that such a spring

has been used in railway practicleast in this Country. This is an appreciable

step forward in suspension design, and perhaps the Author might care to give

us a few remarks on it, and possibly also on the ring type of spring which'

may be used Jl1 similar circumstances. With regard to the proposed method

of equalising, the Author proposes the use of roller or needle bearings for

the levers. I should like to draw his attention to the fact that a number

of experiments have recently been made using roller or needle bearings in

a position of this sort where there is no appreciable rotation, and it is

extremely difficult to get the outer race to stand up to the hammering to

which it will be subjected,

Paper awarded Alfred Rosslin Bennett Prize

Larkin, E.J. (Paper No. 335).

The progressive system of workshop training. 219-32. The embryo locomotive

engineer. 233-44. Disc.: 245-52 + 4 folding plates. 11 diagrs.

Paper presented at the Queen's Hotel, Birmingham on 19 December 12934

at 18.45: Chairman G.S. Bellamy.

Organization of apprentice training for trade apprentices on the LMS at Derby

Works, with some considferation given to the training of Engineering Apprentices,

Premium Pupils and Engineer Pupils.for entrants with an honours

degree..

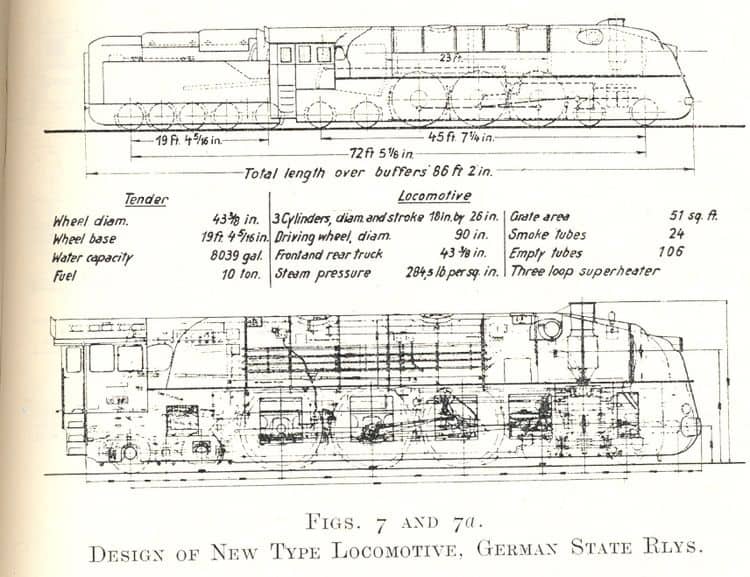

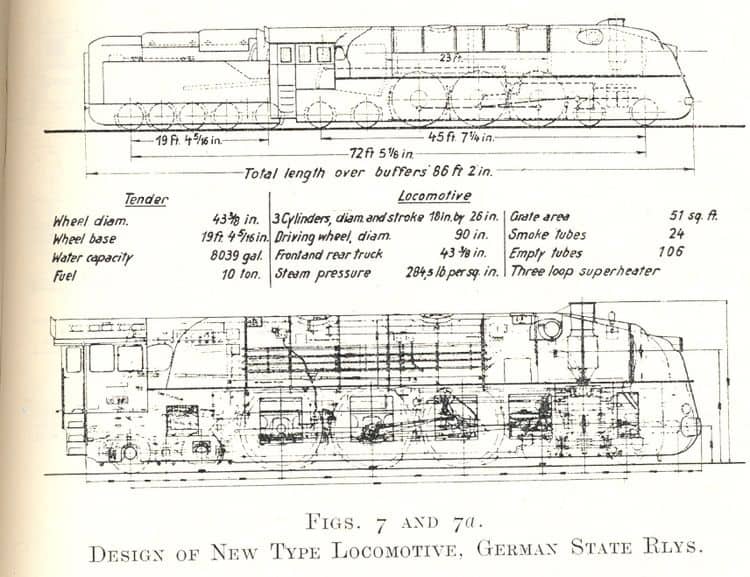

Wagner, R.P. (Paper No. 336).

High speed and the steam locomotive. 254-69. Disc.: 269-85. 5 illus., 6 diagrs.

The Sixth Ordinary General Meeting of the 1934-35 Session was held

in the hall of the Institution of Mechanical Engineers, Storey's Gate,

Westminster, on Thursday, 28 February 1935, at 6 p.m. Mr. H.N. Gresley,

President, occupying the chair.

An experimental 4-6-4 design was described which was intended for very high

speeds (in excess of 100 mile/h). This was fully streamlined with skirts

(petticoats was term used) reaching down to rail level. A special linkage

to the tender was intended to increase stability at high speeds. A 6-6-4T

streamlined tank engine was also described.

|

The following precis appeared in the

Locomotive Mag. (41, pp

73-5): Dr. Wagner opened his discourse with a reference to the old British

single wheelers and then continued with a survey of the main require- ments

in designing a locomotive to be able to run on trains on a 100 miles per

hour schedule. A driving wheel diameter of 7 ft. 6 in. seems adequate and

the number of drivers depends on the number of coaches to be hauled, and

on the wheel load. Figuring on a train of 200 to 220 tons and a load on the

driving axles of 18 tons, two pairs of drivers would seem sufficient; but,

placed between non-coupled leading and rear wheels there is a tendency to

slip. Apart from this, when accelerating, and speeding up to 100 m.p.h. it

seems wise to have a third pair of drivers. A calculation of boiler capacity

and weight shows that at least six pairs of wheels are necessary to carry

the superstructure, and the weight certainly justifies a third pair of drivers.

In a very fast running locomotive a leading . four-wheeled truck with the

very best spring sus- pension imaginable is agreed to by most locomotive

experts; a point where designers disagree has always been the trailing pair

of wheels. Apart from the boiler and frame weight requiring rr.ore wheels,

It would, m locomotives of this size be impossible to leave out a rear support,

because the grate required could never be squeezed between the drivers. So,

when the designer has decided to ar- range a wide firebox behind the drivers

he is practically bound hand and foot as to the weight to be assigned to

the trailing wheels. Calculation shows that usually the weight of the firebox

of a 1,600 to 1,800 h.p. boiler loads a single pair of trailers fully up

to the weight allotted to the drivers; in many cases the load on the trailing

axle even exceeds that on the drivers. Consequently the designer arranges

the trailing wheels more and more to the rear until the load on the drivers

and the length of the engine will set him a limit. At 20 tons wheel load

the firebox still to be carried by a single pair of wheels is that of a 3,000

h.p. boiler. Many a designer, who has to put more h.p. into his boiler, has

found that out and sought help, though not very effective, in a combustion

chamber. The logical help is really another pair of trailers.

It is no great matter whether these trailing axles are independent or combined

in a bogie truck. Two independent axles allow a better layout of the ashpan,

but when the boiler centre is high a bogie truck will give greater steadiness

in running at high speed. Thus the wheel arrangement of a powerful express

locomotive for light trains and high speed is a product of almost compulsory

conclusions.

But another item of grave consideration in designing a locomotive for 100

m.p.h. or more is the air resistance. This can be overcome by employing more

power, but the burden upon the coal budget can be eased by covering the entire

locomotive and tender to eliminate the influence of protruding parts, including

wheels, rods and brake parts. It is hopeless to "streamline" a locomotive,

including the tender, correctly, just as the correct streamlining of railcars

is bound to be imperfect. But a good effect can be obtained by comparing

the merits of various possibilities of covering up a locomotive. The German

State Railways, and before them the Borsig Locomotive Works, had some wooden

models tested in wind channels. These tests were preceded by a number of

air resistance tests run by the German State Railways. They were carried

out on test trains with the object of finding a new formula for the several

factors of train resistance. The result, summed up roughly, was that the

air resistance of passenger coaches could be represented by the formula

0.0048 . (n + 2.7) . f . V/r2,

in which n means the number of coaches; 2.7 a factor representing the air

suction behind the last coach;

f the cross section part of each coach not shielded by its forerunner (equal

to 1.5 sq. metres);

Vr the speed relative to the existing motion of the air (wind

factor).

The tests were made with an uncovered 4-6-0 type locomotive and a train of

standard corridor ooaches.

The wind tests made with small scale models of locomotives show that the

head air resistance could be overcome by retaining the customary designing

practice, but they also showed that power and fuel saving can be attained

by covering. The question of sufficient outlook from a rear cab raised doubts

as serious as the wheel arrangement had. Therefore, it was decided to build

two locomotives, fully covered with cab behind, and later on, one locomotive

with the cab in front, and con- sequently with reversed boiler, which will

be fed with pulverised coal owing to the difficulties of otherwise transporting

coal from the tender to the front end of the locomotive.

The two new type locomotives are laid out as 4-6-4 engines with 7 ft. 6 in.

drivers and rear cab. They are being built at the Borsig Works at Berlin,

and the first has left the shop and will undergo thorough tests at the Grunewald

Testing Dept. The front cabin type cannot be dealt with as the designs are

not complete. The wheels of the front bogie, those of the rear truck and

of the tender are 3 ft. 73/8 in. in diameter in order to keep

the number of revolutions within customary limits. The front truck has an

inside frame almost identical with the truck of German standard engines,

except that one of the two locomotives is fitted with spherical roller bearings

on all trailing wheels. Two helical springs have been added to the longitudinal

laminated spring so that the leading wheels may follow unevennesses of the

rail without overcoming any spring friction. The rear truck has an outside

frame to make room for the ashpan, and has also double spring suspension.

The wheel sets are interchangeable with those of the tender.

The boiler has been laid out for a grate area of 51 sq. ft., for a heating

surface of 2,938 sq. ft. for evaporation and for a superheater surface of

969 sq. ft. The boiler pressure was set at 284.5 lb. per sq. in. This pressure

still allowed for a copper firebox. The diameter of the boiler of the heavy

German Pacific, 6 ft. 3 in., could be retained considering the fact that

the test locomotive requires very slightly more power than the Pacific. The

number of smoke tubes (24) of 6¾ in./6 in. diameter is retained, and

the three-loop superheater of pipes of 1¼/7/8 in. The

number of fire tubes is 106 and their diameter 2¾ in./2ft

9/16in. The length of tubes has, for the first time in Germany,

been made 23 ft. or 8 in. more than the heavy Pacific. The smokebox is rather

long so that the feed-water heater found room behind the funnel; this enabled

the front part ahead of the funnel to be given a sloping top to deflect smoke

and steam from the cab windows. All fittings are of the standard type except

that some have been put closer against the boiler shell, so that the covering

will not interfere with the driver' s outlook.

The centre part of the ashpan, which, due to the bogie truck, is not quite

as spacious as might be desired. contains the main air inlet port and the

hopper bottom; as this air inlet would be in- sufficient for the grate, 68

in. wide, the ashpan has to have more air inlet ports on both sides outside

the frame.

The locomotive frame is of the bar type and 3ft in. in thickness. The smokebox

rests upon it by means of a welded saddle-like structure. To ensure smooth

running at highest speed the locomotive has three cylinders of 18 in. diameter

each and 26 in. stroke, working at angles of 120 deg.; all cylinders are

horizontal. Those outside, drive the second pair of coupled wheels, the inside

cylinder the first pair. All cylinders have independent Walschaerts gear;

the inside link motion has been taken off the second coupled axle by an inside

crank instead of an eccentric. The characteristics of the Walschaerts gear

have been altered to a certain extent to attain wider steam passages at short

cut-off and earlier admission so as to utilise live steam pressure for cushioning

the inertia forces of the rods at high speed. For this purpose the eccentricity

and the link have remained practically the same as usual, whereas the influence

of the crosshead upon the valve motion has been considerably enlarged. Thus

the valve travel is enlarged more than 50 per cent. and the steam passages,

especially during the exhaust period, are fully opened even at short cut-off.

Dr. Wagner then gave details of the braking arrangements and also of a number

of unusual features in the tender. A water supply of 8,000 gallons and 10

tons 0 f coal was considered necessary to run 200 miles without stop for

water and 400 miles without refuelling. These 45 tons of stores with the

requisite framing, tank and bunker, require five pairs of wheels; the first

two pairs are arranged in a bogie frame and the other three pairs are grouped

closely together in the main framing at the rear.

The discussion following the paper was opened by Mr. Gresley, and continued

by Mr. W. A. Stanier, Mr. J. Clayton, Lord Monkswell, and Messrs. Cyril Williams,

H. Holcroft, J. E. Spear, A. C. Carr, J. S. Tritton, W. Redpath, D. W. Sanford

and others .

Discussion recorded in full. The President: The first thing for me to do is to express our thanks to Dr. Wagner for coming over here all the way from Germany, for all the trouble he has taken in the preparation of this Paper and of the diagrams, and in converting his metric figures into figures which we can understand. I take that as a great compliment to the Institution. (Hear, hear.) The great thing is, of course, the substance of the Paper. I t is full of interest. There are so many members here who I am sure would like to ask questions and I have so many questions to ask myself, that I know you would only say: "I was going to ask that question, but the President forestalled me." So perhaps when you have done your questions I might do a little sweeping up at the end. Resume, illustration and diagram in Locomotive Mag., 1935, 41, 100-2

J. Clayton, (269-70).: As one of about 100 members of this Institution who had the great privilege and pleasure of visiting Germany in 1928, when we had such a wonderful reception from our German engineering friends, I cannot miss this opportunity of mentioning that one of the principal people amongst those who welcomed us then was Dr. Wagner. He came all the way from Berlin to Kassel to meet us and to see that we were well shown over Messrs. Henschel's works. In fact, he acted as one of the guides, and journeyed with us to Berlin to visit the German State Railway Works and their special experimental station at Grunewald. As far as the Paper itself is concerned, it should make us all very proud of the steam locomotive. It shows us that the last word, as so many would have us believe, has not been said with regard to it. We were interested in the Author's reference to the road engineer, who is apparently in Germany as big a trouble to the poor locomotive designer as he is in this Country. The engines described by the Author have not got beyond the experimental stage yet, but when the actual drawings appear-as we hope they will-in the Paper as published we shall probably know a good deal more about the details of their design. In passing, the Author mentioned in his last few words something about the metacentric of the engine and that it was not likely to upset so long as the speed was kept under something like 150 miles an hour. Nevertheless, there is always that other factor which may enter into the case, the condition of the road, but the margin of safety is a very substantial one. With regard to the boiler, may I ask what is the material of which the firebox plates and side water space stays are made? Also what curves can the engines such as he has described negotiate safely?

Wagmer's reply: Mr. Clayton mentioned the material of which the side

water space stays are made, but perhaps I may treat of all the boiler material.

For the boiler shell we have a chromium molybdenum steel, a very Iow alloy,

with not much molybdenum and with less chromium in it. The fire-box in this

type of locomotive is still of copper, and so are the stay bolts. But on

some other locomotives, in fact in all locomotives delivered during the second

half of 1935, we shall have steel fireboxes of two different types of mild

steel. This is a steel which has been made under indifferent gases; you know

the process of steel making in which steel is purified to a certain extent;

we call it "aged." Krupp has one patent for it, and there is another firm

in Siegerland.

Mr. Clayton's other question was which would be the smallest curve which

the locomotive could take? It is a curve with a radius of 180m., about 200

yards. On all points of our side tracks we branch off at this same

radius.

W.A. Stanier (pp. 270-1): It is with

very great pleasure that I accept the opportunity of saying a few words to-night,

because I look on the Author as one not only of German but of international

reputation. I have met him in America, Germany and England, and I always

regard the evidence of design that he shows as being of the very highest

rank. I had the opportunity when I was over in Germany two years ago of riding

on one of his new Pacific engines built by Krupp, and the way that engine

took curves at 70 miles an hour did not make my hair stand on end, for it

rode so well. I have therefore come to the conclusion that the Author has

some special way of springing engines which is superior to what I have been

accustomed to. I was very interested in the Paper he gave, and should like

to congratulate him on the many points that he has put before us to make

us think. I consider that what he has done in putting forward this design

represents a step that will make many of us review our designs and review

the conditions that we have to meet. Everything at the present time is for

speed. The general speed of the line has to be raised, and that means raising

not only the power of the engines but also their capacity for maintaining

high speeds. I was particularly interested in the way in which he has got

over his braking problems, but I should like to know how he manages to maintain

the efficiency of the brake on the bogie. Brakes on the bogie have been one

of my problems, and I have given up maintaining them and have taken them

off. I should like to ask why he needs braking on the bogie, seeing that

all his rolling stock is braked. It seems to me that, with the coupled wheels

braked and all the brakes on the rolling stock, there is not so much need

for a finicky little brake on the bogie.

His remarks on boiler design were very interesting, and I should like to

ask if he has used any special material in the barrel plates and firebox

plates to keep the weight down. He has a very powerful engine, and he speaks

of over 18 tons axle .load. For an engine of that power he seems to have

achieved something that is very much better than we have over here. He has

also not referred to the load gauge to which he can build. It seems to me

the advantages they enjoy of having no platforms in Germany and of bemg able

to build to something like 11ft. wide and 14ft: high enables the Author to

get a much better boiler efficiency than we can get with the English load

gauge. Wagner did not appear to give a formal response to Stanier,

D.W. Sanford (p. 271): There are just two questions

on which I should like the Author to give me a little more mformation. He

said that the brake percentage was 180 and that there was some automatic

means whereby that figure could be reduced as the speed dropped, no doubt

to compensate for the increase in the coefficient of friction between the

brake. and the wheel. Could he explain how that is done? . Is it some form

of accelerometer by which, as the retardation mcreases due to the increase

of friction the braking power is automatically diminished? ' Another point

is the suspension of the bogie. At the present time it is the practice on

some of our engines in this Country to take the weight at the side and not

in the centre, whereas. on the Continent, I believe, it is very largely the.

practice to try to take the weight in the centre of the bogie. We know from

experience that the method of having the weight on each side of the bogie

gives you a very good riding engine. I wonder whether the Author could tell

us whether in that particular engine the weight is taken on the centre of

the bogie or on the sides?

Wagner's response: Mr. Sanford asked me what we did to the brake on our bogie

trucks. We have had a lot of trouble with our bogie trucks for the last fifteen

years, but I do not think I have had a letter concerning them for the last

two years now, since we fastened everything on the bogie frame. That means

that all the brake arrangement was fixed on sprung parts, not on parts resting

directly on the journals, as is usually done on bogie trucks.

I cannot compare load gauges figure for figure, but I expect you know the

so-called Technische Einheit or T. E. gauge, which is in use practically

all over the Continent—the Berne unit; the locomotive is within that

gauge. Mr. Sanford asked me a very delicate question about the automatic

brake adjustment. We had delivered to us a casing which looked rather dreadful

and which had a lot of connections outside; one of these connections was

a flexible hose connecting to the journal of one of the rear bogie axles.

So there must be something like a governor inside this box! (Laughter.) I

have not opened it yet.

Mr. Sanford mentioned further the weight of the main frame riding on the

bogie truck. "We have in Germany—in fact in Prussia—put the weight

on both sides of the bogie truck for the last 50 years. That is what one

of the other speakers mentioned later—I think it was Mr. Tritton; he

asked me how we managed to do away with oscillation, and I understood that

what he meant was the oscillation of the leading bogie truck. (Mr.

Tritton:"Yes;'hunting,' we call it.") This is the factor that is playing

such a tragic roLe at present in some of the French locomotives. I am very

happy to say that we have never noticed oscillations of that kind, because

we distribute the pressure of the main frame on both sides of the truck.

That is the most effective damping you can have. The driver does his best

not to overgrease these parts, and so he makes the damping better than was

intended by the designer!

I expect you saw in the slide that we did not send the wheel load through

the leading bogie truck frame. We have the main frame and the supporters

on a platform, and underneath this platform is the balancing level and a

spring, both connecting the front and the rear journal of both the bogie

truck axles. None of the forces, therefore, go trough the frame of the truck

unless a spring breaks. Special provision has been made for this

occurring.

W. Cyril Williams (p. 271) Looking at these most interesting and highly-developed designs reminds one of the limitations of the orthodox type of locomotive, and I am therefore prompted to ask Dr. Wagner if an articulated engine has been considered. The Algerian Railways had just decided to obtain 12 Beyer-Garratt engines for speeds up to 80 miles an hour. The pressure will be 290lbs., and the tractive effort by formula 60,000lbs., with a 3,000 h.p. boiler by the O.C.E.M. formula. Perhaps such a type will open a fresh avenue for exploration in the future. The front tank could be aerodynamically arranged. Wagner's response: . Mr. Williams asked whether we had considered articulated engines. I suppose by his question he meant the Garratt engine. The Garratt engine, I think, has everything to gain as a tank engine and everything to lose as an engine with a tank behind.

E.H. Greg pp. 271-2): Unless I was mistaken, the Author said that the side wind did not matter. I have always understood that the side wind was the one that retarded the speed of the train by driving the train against the rail and the flanges binding on the rail; that a side wind was the important one and not the head wind. Also I think he said something about a side wind being resolved into two forces, that the side wind at right angles to the rail was entirely altered in its character by the speed at which the train is running. That is quite new to me to hear that a side wind has no effect on the retardation of the train. Wagner's response: Mr. Greg asked the question about a side wind. I am very sorry, but perhaps I made a mistake in explaining the mattter. I meant to say: The velocity of the train at fulll speed is something like 50 metres per second in the direction of the line. A fairly hard wind is something like 10 metres per second; that is what we call wind force 10—rather a nasty gale. The resulting angle of the wind is a tangent of 1 in 5, and in most cases it is even as low as 1 in 10, as in the ordinary 5-metre wind. That means that we have to consider the wind as far as the steadiness and the safety of the engine is concerned but we have not to consider wind as detrimental as it usually is to a slowly-moving engine. We only consider it as far as the resistance is concerned.

Julian Tritton (p. 272): I was hoping that the question of oscillation would have been mentioned by the Author. At these high speeds synchronous oscillation must be a difficult problem to deal with. I should like to ask him whether he took any special precautions in the designing of side control gear on the bogie, or an asynchronous system of springing, which would prevent oscillation building up to a dangerous amplitude. Also, would he give us details of the drawgear which he uses between the engine and the tender, and tell us whether this follows German State practice in adding part of the horizontal inertia of the tender to the back end of the engine as a controlling force? Wagner's reply: Mr. Tritton asked me another question about the tender connection. I know a good many tender connections that is one of the reasons why I have always been very conservatlve. We have, apart from two auxiliary bars, just one head bar—as heavy as it can be forged—and we do not make any fuss about it. It has two holes and a little lost motion in both. Besides we have two side buffers with very slightly inclined faces, and a spring in the tender pressing against both buffers. This spring tries to press the locomotive and tender away from one another, so that the slack in the very roughly cut main connecting bar is taken out. The spring acts like a balancer between the right and left buffers and—I think this is one of the good things we had in our Pacifics—has a pressure of 21 tons. That means that we can employ a two-cylinder engine of pretty high cylinder diameter, an engine which would otherwise give a very nasty longitudinal motion to the train; but it does not do this, because we take all the mass of the tender into the mass of the locomotive by employing a spring like that.

H. Holcroft (pp. 272-3): It is very significant

that the Author, after considering various alternative designs, has reverted

to the conventional design of locomotive, and in order to attain a normal

speed of a hundred miles an hour and a maximum of 110, has adopted a 90in.

driving wheel. When running at maximum speed .that represents about 420

revolutions of the wheel per rrunute. We know, however, from our experience

with modern engines having long travel piston valves, that that number of

revolutions represents the ultimate speed on the level at which an engine

can run when merely propelling itself. Owing to wire-drawing and back pressure,

the horse-power of the engine falls off until it is only sufficient to overcome

its own resistance; no further power is available for acceleration and an

ultimate speed is reached beyond which it cannot go unless a down gradient

is reached. It, therefore seems very bold to go in for a conventional type

of locomotive that will actually have to draw a train of five or six coaches

at this speed, in addition to propelling itself. I should like very much

to know whether any special consideration has been given to the design of

the cylinder ports and steam passages. A very large area for cross section

of ports, in order to keep the steam velocity down, is impractical, because

it adds so much more to the compression space. There is another way. to reduce

resistance which might be considered, and in this I think we should follow

the example of the internal combustion engineers and study the streamline

flow, so that steam from the steam chest reaches the piston and finds its

way out of the cylinder with the minimum of eddies. In that way we could

reduce our resistances and so improve the mean effective pressure and so

raise the horse-power at high speeds. I should like to know whether anything

of that kind has been considered in this present design, seeing that the

maximum speed of revolution of the normal locomotive is about 420 per minute.

In the ordinary way we get a maximum horse-power at about 250-300 revolutions,

and after that it begins to fall off, whereas in this locomotive it is desirable

to have the maximum horse-power somewhere about the speed at which it is

intended to run, namely, about 400 r.p.m. We know that in the case of small

high speed enclosed steam engines of modern design, such as are used for

steam rail cars, motor buses and other heavy road vehicles, the speed of

revolution is normally about a thousand per minute; and the maximum horse-power

is obtained somewhere about that speed, while the steam consumption per i.h.p.

hour not only compares well with that of a locomotive, but is actually even

better. If we were able to adopt a much higher speed of revolution like that

we could do with much smaller wheels and so reduce the spring borne weights.

With 90in. wheels plus axle, axle-boxes and springs, together with half the

weight of the connecting rods and coupling rods, the unsprung weight is very

heavy. It could be reduced considerably by putting up the speed of

revolution.

I should also like to know if any special consideration has been given to

the design of the coupling rods. At a speed of 110 m. p.h. the centrifugal

force must be very great, and it would be interesting to know what is the

throw of the coupling rod and whether any special section has been adopted

in the design.

Wagner's reply: Mr. Holcroft and Lord Monkswell specially asked about the

way in which we get the steam into the cylinders, and remarked how we got

it out again. Mr. Greg added the question: "Why not have poppet valves?"

Perhaps I had better start on the last question. The poppet valves to us

are an entirely open problem. We have a Caprotti engine for the last 20 years

we always had Lenz trial engines, which shows that we have not gIven them

up altogether. We have studied the poppet valve. problem, and I think that

the best valve I have yet found is the one mentioned by Mr. Gresley, the

Cossart valve, because that has not to be accelerated from a standstill in

the very moment steam is admitted. The acceleration begins earlier than the

steam admission. Take a system of movement that would make the whole Cossart

or Kerkhove valve move in a way which would give the smallest possible

acceleration, and therefore the slightest wear, and you have the link valve

motion. So for this reason I have always stuck, so far, to piston valves

and rather tried to improve their weak points. There is no saying that we

shall not some day or other see something better in the poppet valve, but

so far we have taken the following measures to improve the passage of the

steam through the cylindcr. We have cylinders of 450mm. diameter—that

is 18ins.—and we have made the valve chest 12ins. in diameter. Without

giving too much cubic clearance we altered the gear in the way I described

so that the pre-adrnission is very early; that does no harm in a very

fast-running engine, because there is still some residuary pressure.

Compression, in a year like this, comes pretty early; besides, we have formed

all the channels so as to make the velocity of the steam as low as possible

and to guide it in the direction in which it should flow. You remember, perhaps,

the patents of Professor Gutermuth, who tried to form the piston valve like

a nozzle. We cannot afford a nozzle, but we have done our best to guide the

steam. From our experience so far I can say that if some of you gentlemen

had the chance to ride on out locomotives and to see the back pressure, you

would see that we hardly ever exceed 1.5Ib., at full output. I hope that

in our later types we have improved on that; sometimes we get to half this

figure.

Mr. Holcroft spoke of running parts, and asked why we did not build an engine

with single fast-moving steam motors. I said in my Paper that we had considered

that, and we found from a preliminary calculation that an engme with three

independent drivers would not have stood much lower, in spite of the fact

that the drivers could have been made lower. Perhaps the day will come when

the individual drive will be absolutely necessary; that is when somebody

asks us to go beyond 140 m.p.h !

Mr. Holcroft mentions the coupling rods as well; I cannot show you the section

or the slides, though I am sure you would be interested in their design,

because a great deal of attention has been given to them. The section, of

course, is an "I" section, and I may just mention that the rods look rather

clumsy. The web is about half an inch thick, and the top and bottom flange

about five-eighths of an inch, and everything is heavily rounded off. I think

there is nothing to trouble us about the rods. By the way, we had a test

of the rods without really intending to in the yard of the makers. There

was a very large wet spot and the engine began slipping; the throttle stuck,

and just for a second the man could not shut it—and the engine did more

than 110 m.p.h. for that second!

Lord Monkswell (273-4): When

I was a boy at school and read W.M. Acworth's book on the Railways of

England —one of the best books I ever read in my life—it struck

me: "Why on earth should not we, all of us, go very much faster?" From that

day to this I have never found any real answer to that question. In my own

little way, I have been seeing quite a lot of what I consider to be an

exceedingly advanced type of engine—with that, I think, we all of us

here agree—M. Chapelon's engine on the Paris-Orleans line. I was very

much interested to compare, as far as I could, the design of the Author's

locomotive with that of M. Chapelon. The particular features that have struck

me include the extreme ease with which the steam is got through the cylinders.

The business about balancing the reciprocating parts and the strain upon

the rods does not seem to present much difficulty, but where the French design

seems to be so extraordinarily good is in just this point that I mentioned.

First of all, as I understand it, one has to get the steam as fluid as possible,

and in order to get the steam as fluid as possible one has to have exceedingly

high superheat. I was on one of these engines last summer, and the superheat

rose to 800°F. I should be very interested to know what temperature

the Author uses in his engines.

The next thing is the enormously big steam pipes. I should imagine that the

Paris-Orleans engines have steam pipes of about twice the section that engines

have usually been given. Perhaps the Author could tell me about that. Then

we come to the valves. I may say that I was enormously struck by the way

in which these valves worked.

In 1933 the Chemin de Fer du Nord allowed me to travel on one of their engines

fitted with ordinary piston valves, between Paris and Calais. I will just

take the Survilliers Bank: the engine was practically the same weight as

the Paris-Orleans Pacific which I accompanied in 1934, and the train was

the same weight; the weather was about the same, and the comparison was fair

in every way. In 1933 the Nord engine took a train up the Survilliers Bank

at an average speed of somewhere about 70 miles an hour with a cut-off in

the high pressure cylinders of 60 per cent. In 1934 the Chemin de Fer du

Nord had taken over some of the Paris-Orleans engines with poppet valves,

and a train of the same weight up the same bank in the same weather conditions

ran rather faster than the year before, with a cut-off in the high pressure

cylinders of only 40 per cent. It was perfectly astonishing the way in which

the steam got through the cylinders. I do not understand that there is anything

in the nature of poppet valves in the German engines, but perhaps the Author

could tell us what arrangements he has made for getting the steam rapidly

through the cylinders.

Then there is the question of the blast-pipe. There again, the double blast-pipe,

without any bother of variable arrangement, is an enormous simplification

and it seems to me to work in the most astonishing manner. If the Author

could tell us something about his blast-pipe it would be very interesting.

Wagner's reply: Lord Monkswell spoke about the 800° usually attained

by French locomotives. That is about the figure that we reach on our locomotives,

and we find, just like our French colleagues, that it is about the highest

figure we can do on our oil. In a few compounds we attain 900°. We found

that our simples could still be run at 800°F., and perhaps a little

more, but this temperature did not prove satisfactory in high pressure cylinders

of compounds. I am quite sure that we always put piston rings into the pistons

before starting, but sometimes we arrive without any!

A very interesting idea underlies the dimension of steam-pipes. We found

that it is very good for the locomotive to increase the admission pipe so

as to make it a sort of reservoir. We did it as well, and we also increased

the exhaust pipes so as to give us as slow a steam velocity as necessary.

I do not quite agree with Lord Monkswell about the importance of the cut-off

of the French locomotives in one case and the other: 60 and 40 per cent.

What he apparently had done was to run both locomotives at full boiler capacity,

and this is as much as could be done. When the admission temperature has

been 800° and has been run down to condensing point, and when the steam

has been expanded fully to atmosphere, that is all you can expect of the

cylinder, no matter what the distribution looks like.

Lord MonkswelI: Perhaps I may add that the water consumption corresponds

to the difference in the high-pressure cylinder cut-off. The water consumed

between Paris and Calais by the Nord engine was 28 tons, and by the Paris-Orleans

engine 22 tons, so it certainly looked as if there were very great economy.

Dr. Wagner: There may be many reasons for that. Either the piston valve

distribution was not m the best of order or the locomotive was not in the

best of order, or there' were four years of difference in the age of the

locomotives. All those things may have a hand in it—I do not know. (Lord

Monkswell: "No.") You would have to know all the details of the case.

The blast-pipe problem is very interesting. There is a great deal in the

design of the double blast-pipe. We are going to give it a trial and we expect

something from it. We have tried to go along on the same system without using

the intermediate nozzle. When the Finnish locomotive engineer Kylälä

(Kylala). came to me in 1923 we had our system ready and we had it put on

our first 20 locomotlves. Our system is different; it makes the stack as

wide as possible according to a very simple formula we have evolv~d for ourselves

from experience, making the exhaust as wide as possible and putting it down

as far as possible. The blast-pipe in our locomotive is between four and

six inches above the floor of the smoke box; that gives the upper cone of

steam as large a surface as possible. We shall have to see whether the Kylchap

brings us something extra or not; I cannot tell you, but I know that we raise

3¼ins. of water column in the smokebox by using a back pressure of something

like 0.5 to 1 lb.

W. Redpath (pp. 274-5) : As I understand it, the efficiency of the engine is increased somewhere in the neighbourhood of 16 to 20 per cent. by the fitting of the petticoats. One would like some information as regards the cost. I should also like to know what the thickness of the steel or any other material is that he has used for the petticoats, and also for the upper clothing of the boiler. I think these are all facts that will be of interest to designers here in connection with increasing efficiency of their locomotives in the way that the Author has indicated.

J.E. Spear (p. 275): It was particularly interesting to hear the Author mention that the engine was fitted with roller bearings on the leading bogie, and, it appeared from the drawings, on the trailing bogie as well. This of course is not surprising in view of the fact that the German State Railways have used roller bearings so extensively on their coaching stock, but I should like to hear whether he has considered roller bearings for the coupled axles either of these or subsequent engines, and to have his views in that respect. In answer to Mr. Spear, who pointed out that we had roller bearings on our bogie axles and not on. the coupled axles and that they were more trouble on bogie axles: we did it on purpose. It seemed impossible to us to have them on both rods and axle bearings, because you have to give one or both of them so much longitudinal tolerance that all the good that comes in from the bearing is taken away again by increased pounding. In uncoupled wheels, conditions would be better.

A Speaker (p. 275): May I just ask one question? Is it expected that the engines will be hand fired or mechanically fired? Dr. Wagner : They will be hand fired.

The President: (Gresley pp.

275-7) Actually Mr. Sandford is the

only one who has asked a question that I was going to ask: that was with

regard to how the air pressure is controlled proportionately to the speed.

That is, if you have a brake which is braked to the extent of 180 per cent.

of the weight between the tyre and the rail, as the speed comes down you

mentioned that you. have some device for reducing the pressure automatically

With the speed. I have seen devices of that sort but they have generally

been controlled on a time limit basis. If you have one on a time limit basis

and happen to have an emergency application when you are going about 12 miles

an hour, the wheels automatically pick up and you get a flat on your tyre.

No doubt the Author has some arrangement with the Westinghouse brake by which

the pressure is proportioned to the speed.

I am going to ask why he has such very large diameter driving wheels. Lord

Monkswell was telling us just now, as he has told us in the press several

times, about the wonderful speeds that are attained on the French railways.

I have travelled a great deal on French railways and know the French engineers

well. Many of them are old friends of mine. But I was surprised when M. Lancrenon

told me some years ago, after he had brought out his new tank engine for

working Paris suburban traffic (a tank engine with coupled wheels about 5ft.

in diameter and Cossart valve gear which provides for a very easy escape

of steam), that running between Creil and Paris one day, when one of the

big engines had the misfortune to break down, one of these tank engines was

put on and did the run from start tu stop in less time than they had ever

done it with the Pacific. The reason was, of course, that it was able to

get rid of the steam so easily. I do not think it is essential for excessive

high speeds to have a wheel of 7ft. 6ins. diameter.

Of course, Dr. Wagner, you know that when you come to England we criticise

you very freely and very openly, and you must take it all in good part. (Dr.

Wagner: "I am sure I do.") Another criticism I have to make—you will

think I am rather captious—is that you are talking of a 220-ton train,

and I do not exactly remember what the weight of the locomotive is, but it

is not far short of that of the train. It is a big engine with an 80-ton

tender, and the engine weighs 120 tons, making a total of 200 tons of engine

for 220 tons of train. That seems to me a great deal. I do not know what

your Diesel friends will say! You said in the early part of the Paper that

in order to help to reduce the weight, it is suggested by some engineers

that they should have what you called a "not very effective" combustion chamber.

That is a very interesting point. I notice in your design that you have not

provided a combustion chamber. During some trials we recently had in Paris

with the L.N .E. engines, at which one of the Est engines was also being

tried, I noticed one marked difference—the Est engine was better than

ours in the absence of smoke due to the enormous combustion chamber, it was

about 6ft. long. This was a very long-barrelled engine, and they had cut

their tubes down to a reasonable sort of length and used it to reduce the

weight at the back end. That, however, was not the main object; it was to

get more complete combustion, and I may say that directly they began firing,

within two or three seconds, the smoke entirely disappeared.

I cannot say the same of the other engines. Their explanation was that the

big combustion chamber tended towards the burning of smoke and gases. On

your engine I noticed that you have not even got a combustion chamber at

all but no doubt you have special reasons for your design. I am only mentioning

that because the French seem to be very keen on having large combustion chambers

and thereby of course, reducing the weight of the back end of the engine.

Another thing is why have you such a very small superheater—24

elements—on that great big engine? We have heard it suggested here that

one of the important. things is to get high superheat. I have 42 elements

in my engine, nearly double the number and do not get a very high degree

of superheat. As for 800°F. superheat, Lord M.onkswell may not be aware

that 15 years ago we were runnmg engrnes on the Great Northern Railway with

800°F. of superheat—the old Atlantic engines wIth. a 32 element

superheater; that is when they were working pretty hard. I often observed

over 800°F. indicated by the pyrometers; it may be suggested that the

pyrometers were not quite correct. I had them checked and rechecked before

and after, and they were correct. So there is nothing unusual in 800°F.

of superheat. French engines are runnmg at that, but anything beyond that

is too high and burns up the oil.

Reference has been made also to the double blast-pipe. I am. very interested

m this question and have had some very interesting and wonderful results

with it and I should be. interested to know why it is that you are not using

this so-called modern innovation. The double blast-pipe is not really modern

as it was made when I was at Crewe and I helped to make the engine that was

so fitted. It was a badly designed one and, of course, was a failure!

I wish, on behalf of all of us here and on my own personal behalf to express

our thanks to Dr. Wagner for coming. over here. It really is most complimentary

to this Institution that we should be the first as I think we are outside

Germany to hear details of his latest locomotive.

Dr. Wagner (p. 277 et seq), in reply: Let me first express

my heart-felt thanks for the kindness with which you have accepted my Paper.

You can irnagine what pleasure it was to me to read it to you and in your

midst and to ask for the strongest and strictest criticism that I could get

or expect In any circle of experts all over the world. We have attempted

to do something new in some ways, and we have laid ourselves open to criticism;

I am very grateful to you that your crrticism is so much to the point and

so valuable to the cause we all serve.

Mr. Gresley mentioned the Diesel engine. The comparison between steam and

Diesel is the problem of the day. I do not know what to say about this subject:

I think that we shall never be able in ordinary locomotlves to compare with

the Diesel as far as economy is concerned. Of course we cannot, but the one

thing .at which we can so far beat the Diesel engineers, and I thtnk we shall

have to keep up to that, is in always having just a couple of hundred horse-power

behind us.

The combustion chamber is another open question, but we have not used it

so far because we are afraid of the maintenance cost for stay bolts, and

of the lowering of the superheat in the present type of superheater. What

the President says is right, that in France the combustion chamber has proved

very useful for taking up the smoke, and so on, from a very rich but very

nasty smoking coal. In the type of firebox we have used so far we have reached

12 to 14 per cent. of CO2 without the combustion chamber. That

has always convinced me that the combustion was still all right. It may not

be so in the next case we touch upon, but so far we have had fair

combustion.

The smallness of the superheater is admitted but we have a different type

in our long boilers. You know a type with three loops and only one return.

The best recipe for gettmg a good superheat is to send dry steam into the

superheater. .One of the items of design without which none of our boiler

designers gets past me is that he has to answer. the question: "When the

glass is half full of water—whlch. means the ordinary running

condition—what is the velocity of the steam passing through the water

surface?" If the speed is more than one foot per second, he has to increase

his boiler diameter. So far as our tests have gone, we have found that moisture

of the steam is in that case within reasonable limits, below three or four

per cent., and that always gives a good superheat.

Communication from Mr. P. A. Hyde. (p. 283 et seq)

In regard to Mr. Spear's question as to why roller bearings had not been

applied to the driving axles also, I failed to catch the Author's reply clearly

but gathered th.at difficulties with side play governed the decision to stick

to plain bearings for the coupled axles. Taking this as being the reply,

I think that it is well that it should be recorded that some ten fast and

heavy engines, having all coupled axles fitted with rollers of two makes

are in service in the [United] States, and as far as the writer has been

able to ascertain by inquiry, the results are good, and in the case of three

engmes extraordinary.

The first engine put into service was the Timken 4-8-4 machine and this must

now have run a very considerable mileage. The.New York Central have had two

engines in service in what is the most trying service possible viz

the run between Windsor and Harmon some 960 miles at speeds reaching 75 miles

per hour, while loads run to as much as 1,400 tons. One engine with Timken

bearings had, when last I was given information on the subject, run 350,000

miles, while the other with S.K.F. bearings had run .380,000 miles. As this

mileage has been made in about three years there can be little wrong with

either layout.

The Delaware and Hudson has had two engines in service for about the same

time with satisfactory results, and a third, with Drivers S.K.F. fitted,

has also the big end and centre coupling rod eye fitted with rollers, the

results up to some 60,000 miles being satisfactory.

The Lackawanna has a number of engines at work and more being fitted, while

there are several other roads who have placed orders for similar equipment,

so that the total, built or building, cannot be far short of forty engines.

I would recommend, to those interested, a study of the report by the Committee

on Locomotive Construction, of the American Railway Association, on " Roller

Bearings for Locomotives and Tenders." In a table attached to this, which

gives the answers to a questionnaire on the subject, it will be found that

as far back as 1933 three lines were more or less in favour of the use of

rollers in coupled axle bearings, and to-day all of these, and at least two

others, have apparently satisfied themselves that they are a good thing,

as they are placing orders for a number of engines so fitted.

I believe that in a number of these engines over ¾in of side play is

given, under special control, in one or other of the boxes and that no trouble

results.

The main point is that at least three engines have made over 300,000 miles

in less than three years, and if this can be done there cannot be much wrong.

The Author's conditions may, however, differ very greatly from those in existence

in the States, and he is of course the best judge of them. It would, however,

be most interesting to have further remarks from him, especially on the facts

above stated.

Wagner's reply: I did not mention side play as a reason against using roller

bearings in coupled-wheel systems. What I mean is: The distancing tolerance

of two-wheel centres in the frame cannot economically be made less than ±

1/264 of an inch; the tolerance of two bores in a connecting rod is the same,

therefore by keeping inside these limits a difference in length between both

of 1/132in. may occur. This is more than the play in roller bearings, and

I am afraid it would strain the rod and perhaps cause the breaking of

rollers.

We are going to try that out in some ordinary locomotive, but I think that

no locomotive designer can be blamed for not putting roller bearings into

the first specimen of an extra fast running engine.

McDermid, W.F. (Paper No. 337).

Brakes for streamlined railway vehicles. 309-42. Disc.: 342-68. 4 diagrs.,

2 tables.

The Fifth Ordinary General Meeting of the 1934-35 Session was held

in the hall of the Institution of Mechanical Engineers, Storey's Gate,

Westminster, on Thursday, 31 January 1935, at 6 p.m. Mr. H.N. Gresley, President,

occupying the chair.

The following precis was published in

Locomotive Mag., 1935, 41, 44-5. At slow speeds the efficiency

of brakes is relatively high, and the train resistance factor becomes almost

negligible; but, particularly if it happens that the rail condition is greasy,

and therefore bad for braking, when a short train is braked at say from 65

to 70 m.p.h. probably as much as 6.5% of the retarding force will be due

to the train resistance, while for a long train at similar speed it would

amount to about 5%. Obviously any reduction of the resistance by stream-lining

the vehicles will to a like extent also render deficient the possibility

of its retardation. Thus, whilst much thought is devoted to a rapid accele-

ration at starting, in most cases, apparently, but little consideration is

given to new or improved means for making a rapid stop - even though stops

made quickly certainly reduce train running times.

Assuming that a train of some given weight is travellmg at 30 m.p.h. and

that at that speed the total energy in that train is represented by unity,

or .1; then, at 60 m.p.h. the total energy in that tram would amount to 4;

at 100 m.p.h. it would- be 11.1, and at 140 m.p.h. it would be 21.7 times

what it was at 30 m.p.h; thus it is clear that high speed calls for the highest

brake efficiency obtainable.

The author divided his subject into two main features, firstly dealing with

train - resisting quantities, and then examining the limiting fac- tors of.

the po:ver brakes now used; particularly emphasising differences in their

operating times. The determination of train resistances were dealt with under

five headings, summarised as. follows :-

(1) Journal friction, due to the rub- bing. of the journals on the brasses;

(2) rolling friction, due to the rolling action that takes place between

the tread of the wheel and the rail;

(3) track resistance, due to the compression of the track. as the train advances;

(4) flange action, occasioned by the side pressure of the flanges on the

rails ;

(5) air resistance and wind effects caused by the force of air on exposed

parts. This review follows the order adopted by Prof.

Carus-Wilson in his classical paper

read before the Institution of Civil Engineers in 1907. As to actual

braking the author referred to the investigations of Captain Douglas Galton,

on the L.B. & S.C.R. near Brighton in 1878, as well as those made on

the Lake Shore and Michigan Southern R.R. in 1909 and known as the Lake Shore

Emergency Brake Tests, and a third series carried out by the Pennsylvania

R.R. in 1913. In discussing the methods of braking, the author dealt first

with adhesion, and wheels skid- ding. The percentage of retardation, or brakes

efficiency when the results of an actual stop are being considered are covered

by the time taken to stop, the distance stopped in, and the initial speed.

The rate of propagation varies with the type of brake used. Assuming a train

of 20 passenger vehicles each 50 ft. long, has to be controlled, and that

an emer- gency brake application to full power has to be made. With the ordinary

vacuum brake, full power will become effective on the last vehicle in just

about 20 seconds after the first movement of the brake handle, provided each

vehicle has two 15- inch cylinders. If larger cylinders are in use, and they

should be, of course, the time allowance must be increased. "With the ordinary

Westinghouse brake, full power on the 20th vehicle will become effective

in just about 5 seconds, whatever the size of the cylinders may be.

Obviously, with both brakes, there is a period during which, on average,

the brakes are only partly applied. Perhaps about half the above times represents

this period of comparatively free runnmg. If the brake application has to

be made when the train is running at 60 m.p.h., or 88 ft. per second, the

free running times suggested corre- "pond with distances as under i-s- Ordinary

vacuum brake, free running for about 275 yards.

Ordinary Westinghouse brake, free running for about 100 yards.

In releasing the brakes, the last cylinder on the vacuum fitted train would

develop a piston movement in just about 30 seconds. Other factors of the

subject in which the author dealt at length were the friction of brake blocks,

the effects of pressure intensity, mean coefficients during stops, the effects

of temperature on friction of brake blocks, the effects of speed, the effects

of "hard- ness" in brake blocks, and the instantaneous coefficient of friction

at any speed.

Increasing the brake power by a greater leverage ratio is bad practice. The

effects of pin wear nount up leading to false travel of the brake iiston

and waste of power, while the "springing" If long levers aggravates the trouble.

In his conclusions the author asserted that the cylinder power of brakes

at present fitted to passenger stock in this country seldom exceeds about

90% of the weight of the vehicles; at speeds of 60 or 70 miles an hour this

amount of power is insufficient to enable full advantage to be taken, even

of the minimum wheel and rail "adhesion" when the rails are greasy, therefore

unnecessary risks are being accepted without justification- and this at speeds

which are quite normal. If really high speeds are contemplated, it appears

that in addition to using more powerful brakes, it would be advisable to

find out whether or not the "adhesion" factor can, in effect, be increased

by magnetic or other means. At present the brakes on a train of only ten

vehicles may take seven seconds to reach full power, and it may take ten

seconds to release the power. Pressure brakes on this ten-coach train,

electrically controlled, could be applied in two seconds and released in

three seconds. A difference of 12 seconds per stop, with stops necessary

at intervals of, for instance, 3 minutes, as in suburban working, represents

a useful saving of public time; but for faster trains, brakes quicker in

action, and more powerful than at present, are a necessity.

Factors which influence braking performance include journal friction; rolling

friction; track resistance; flange action; air resistance and the effect

of wind. Brakes are affected by adhesion and notably by wheels skidding.

Measures to evaluate braking efficieny (the rate of retardation) are examined.

The friction of brake blocks is influenced by pressure, temperature, speed

and hardness. There are several references to the work of Douglas Galton.

The wear of brake blocks is related to their hardness. Gresley

chaired the meeting and introduced the discussion (pp. 342-4) who considered

that the author had placed too great stress on cast iron brake blocks. He

noted that the German high speed trains, Flying Hamburger, were fitted

with electro-pneumatic brakes, slipper brakes, of the type fitted to tramcars.

These are cobined with Ferodo drum barkes, He commented on Michelin railcars

fitted with pneumatic tyres and commented favourably on their performance

on wet rails. See A4 class: Gresley contributed to discussion. "Streamlined"

implied high speed rather than streamlined per se.

Fifth Ordinary General Meeting of the Newcastle-on-Tyne Centre held at the

County Hotel, Newcastle, on Tuesday 19 March 1935, at 7.15 p.m.; chair taken

by G.M. Wells. E.D. Trask (p. 364) noted that Ferodo brake

blocks were then being used on surface lines, rather than just on underground

railways. G.M. Pargiter (pp. 364-5) noted that drum

brakes were fitted to the light diesel electric railcar and appeared to be

very efficient.

Place, P. (Paper No. 338).

Locomotive testing plants (with special reference to the Testing Plant at

Vitry). 380-406. Disc.: 406-15. 14 illus., 2 diagrs.

Eighth Ordinary General Meeting held in the hall of the Institution

of Mechanical Engineers, Storey’s Gate, Westminster, on Wednesdap 17

April 1935, at 6 p.m., the chair being taken by the President, H.N. Gresley

The following precis appeared in

Locomotive Mag., 1935, 41, 157:

The author described in detail the method of making tests and remarked that

they ensured accuracy within 5 per cent.

The wheels of the locomotive to be tested rest on rollers which turn with

them. The rollers are braked by suitable brakes. As a result the locomotive

is supported on the rollers as it is usually on the rails, and can exert

a tractive effort on a dynamometer to which it is connected by its drawbar

and pin.

The speed of the locomotive is varied by braking the rollers more or less

heavily.

The dynamometer measures the tractive effort corresponding to each speed.

The circumferential speed of the locomotive wheels is also measured, and

by integrating the tractive effort to the distance travelled the work done

at the tread is obtained.

Special instruments, such as pyrometers, pressure gauges, vacuum gauges,

combustion gas analysers, etc., are available for use in connection with

boiler tests and in preparing the heat balance sheets. Other instruments

are provided in connection with the tests on the engine and of these the

following general conditions may be noted.

A. Accuracy.-This depends upon-

The apparatus selected:

The way it is used;

Checking its accuracy and keeping it in good repair;

The method of making the tests; and

The operators.

B. Conoeniency

This depends upon-

The ease with which the instruments can be used;

The possibility of being able to record the results

The instr:uments standing rough usage, that is, upon their being strongly

made and easily kept in repair.

C. Caoacity

The test plant must be capable of testing the largest and most powerful

locomotives, not only at the present time but also in the rather distant

future.

The Amsler instruments are to very rigid requirements as the following will

confirm:

The maximum differences between the registered and the real values recorded,

are:-

Speed and pull, well below 1 per cent.

Work done, below 2 per cent.

Power, below 3 per cent.

The Pyrometers are exact to within 1 per cent.

The automatic smokebox gas analysers are very accurate but are used as indicating

instruments only. The heat balance sheets are based on analyses made with

the Orsat instrument.

The coal and the ashes are weighed on a weigh- ing machine to within 1 per

cent.

The ash is collected in the smoke duct in the roof; the velocity of the smoke

is low in this duct and the ash drops into it. It is then removed and weighed.

The cold water fed into the boiler is measured by graduated tanks. Water

lost at the injectors is collected and measured. The hot water actually injected

into the boiler is measured by piston meters correct to the thousandth part,

and this enables investigation of problems relating to injectors and feed

pumps.

Gresley opened the discussion (406-8): 'One of the

points that impressed me very much in the Paper was the Author's statement

in the last paragraph but one: "Tests repeated under identical conditions

at several weeks' interval on the same locomotive give results which only

differed very slightly, for example, by 5 to 10 h.p. on 1,500 h.p." That

means that if you put an engine on the plant and set the brake so that the

speed of the engine is, say, 120 kilometres per hour and you have a full

boiler pressure, the regulator open fully, and the valve gears arranged for

a certain cut-off, say 20 per cent. or 25 per cent., a month afterwards you

can put that same engine on the plant and you will get exactly the same power

recorded. You can do it over and over again, and, if you repeat the conditions

of the engine, you get the same power recorded on the chart. If you vary

the engine, make a slight alteration in the valve gear and a slight alteration

in some detail of the cut-off, and put the engine on the plant again, you

will get different results. As all the conditions have been constant under

the two tests, you can be fairly certain that the differences which are recorded

are due to the different fittings or the differences that you have made in

the engine. Thereby you can assess with almost complete certainty the value

of any new fitting which can be applied to an engine. If you have not got

a testing plant and you run the engine on the road, make an alteration to

it and run it on the road another day, you may get entirely different results.

If you run it on the road a third day, having restored the engine to its

original condition, you get further different results. The same engine running

day after day gives entirely different results owing to differences of

weather, of speed and of wind. All those variables are eliminated in

a testing plant.

Dr. H. J. Gough, F.R.S. (408): I have had

opportunities of inspecting and studying several locomotive testing plants

including those at Altoona, Illinois, Swindon and at Vitry I am of the opinion

that all the lessons and experiences available from previously existing

plants—including that established in

Germany—have been incorporated to produce at Vitry, what

is, undoubtedly, the finest test plant in existence. With the President,

I was privileged to witness tests at Vitry on the very latest British and

French types of locomotive. I consider that, should a testing plant be installed

in this Country—which I hope will be the

case—there are several further improvements which could

be introduced into the design, although, as the Author remarked, these would

concern detail rather than essential principles.

At Vitry I was particularly impressed by the Amsler dynamometer and recording

gear. I am acquainted with this type of Amsler design in other

directions—particularly in regard to testing

machines—and consider that their applications of the

hydraulic principle form examples of the highest craftsmanship. Their use

of the sphere for integrating purposes—as embodied in

the Vitry recording table—is a most interesting, and,

I believe, a novel development.

On the general question of the uses of a locomotive testing plant in this

Country, should one be installed, one aspect will, I hope, not be lost sight

of; I refer to the need for devoting much attention to research as against

mere routine testing. Although different types of engines would give different

results, it is not necessarily possible to estimate accurately the reasons