|

Richard Edward Lloyd

Maunsell

In 1969 Jones stated that the Southern

policy of suburban electrification reduced the amount of capita! available

for steam development. Further, the Brighton electrification of 1933

convinced the management that this form of traction could be extended to

most of the system. In spite of this background Maunsell was able to produce

several designs which may be regarded as significant in relation to total

development.

Cocks' History of Southern locomotives

to 1938 must be considered the definitive source, but this material is

greatly augmented by Holcroft's books,

and to the very extensive written contribution to Cocks' paper (perhaps Holcroft

considered that the paper should have been written by himself, but

Cocks could be more objective). The prominence of Holcroft' as an authority

on Maunsell may be gauged by following quotation from the preface of O.S.

Nock's The locomotives of R.E.L. Maunsell, 1911-1937: "My most patent

debt, however, is to Mr. Holcroft, who has not only made available to me

the notes from his personal diaries extending over 23 years, but has written

to me a volume of letters amplifying the various entries". Holcroft's books,

based on his diary records add to the depth of our knowledge about Maunsell,

and suffer only from a lack of balance, which is an inherent fault in diaries.

Clayton's contribution should not be ignored:

perhaps its most extraordinary and obvious feature was the failure to adopt

the drumhead smokebox on the Schools class and the firm rejection of derived

motion for three cylinder designs.

D.L. Bradley's The locomotives of the South Eastern and Chatham

Railway surveys Maunsell's "Ashford" designs with usual RCTS thoroughness.

O.S. Nock's The locomotives of R.E.L. Maunsell, 1911-1937 collates

much data on performance and adds some details of Maunsell's Irish activity.

Much of the above still stands, although there is a new biography by Chacksfield

which suffers from a lack of bibliographical exactitude: sources are not

really cited and the rather good book by Nock is not mentioned.

Chacksfield is by far the best source

for strictly biographical material, however. There is also a useful

pictorial survey of Maunsell's work by Haresnape.

|

Patents

3778/1913. Improvements relating to steam superheaters.

with George Victor Valentine Hutchinson. Applied 13 February 1913.

Published 18 December 1913.

19,269/1914 Improvements relating to steam superheaters.

with George Victor Valentine Hutchinson. Priority 13 February 1913.

Applied 31 August 1914. Published 26 November 1914.

NB This patent was granted whilst Maunsell was still with the GS&WR

in Dublin

192,985 Improvements in or relating to condensers for lubricators

of the condensation type with James Clayton. Applied 1 July 1922.

Published 15 February 1923.

202,523 A double-feed lubricator. with James Clayton.

Applied 30 August 1922. Published 23 August 1923.

Maunsell's papers

Presidential Address. J. Instn Loco. Engrs, 1916, 6, 125-33.

A design may be theoretically correct, but for some local reason does

not work out in practice, and the defect and its cause only become apparent

when the engine is put into service. An alteration in the position of an

oil-hole or the shape of an oil groove may sometimes make all the difference

between an engine which is a source of trouble to a foreman and one which

commands his confidence, and in like manner a slight alteration in the height

or shape of a blast pipe or the length or shape of a brick arch may convert

an engine, which a driver considers " shy for. steam," into a free steaming

engine. As I have said, it is practically impossible to guard against such

minor defects creeping into a completely new design, and in order to keep

them within the narrowest possible limits, I am strongly in favour, when

a new class of engine is called for, of only building one in the first instance

and waiting until it has been thoroughly tested for some months on the road

before proceeding with the construction of any more. An obvious objection

to this practice is, of course, that it is more costly to build one engine

than a batch of, say, six or eight. I freely. admit this, but I contend the

additional expenditure so incurred is not only warranted, but may sometimes

prove to be the means of saving considerable outlay in alterations to a larger

number of engines.

During the trial period above referred to, any defects which become

apparent can be noted and remedied, the engine can be indicated and the valve

setting adjusted, and the whole machine " tuned up" to become a model for

similar engines which are to follow. I also contend it is most important

to disperse as quickly as possible any pre judices against a new class of

engine which may arise among the running staff in consequence of the development

of minor defects before referred to,. and these defects can be more quickly

remedied in one engine than in a larger number. If the best work is to be

obtained from a machine the operating staff must have absolute confidence

in its reliability, as well as in its efficiency.

I now come to the objections that may be raised by the shed fitting

staff in consequence of the inaccessibility of parts, which, in the ordinary

period between shop repairs, must from time to time be removed for examination,

repairs, or renewal. Defects in design of this nature are much more likely

to occur in these days of big engines than they were in the days of comparatively

small engines when plenty of space was available for the arrangement of details

and present-day refinements with a view to economy were not a feature of

the design. Road gauges, platform gauges and tunnel gauges remain practically

as they were. Increased allowances in weights and wheel bases are grudgingly

granted, or perhaps I should say extracted, while all the time the call for

engines of greater hauling capacity is incessant and insatiable.

Not withstanding the difficulties nowadays occasioned by want of space,

I hold that defects of inaccessibility should not occur, and if they do,

they are a reproach on the supervision of the designer. Not only are such

defects extremely annoying to the shed fitting staff by causing expenditure

of 'unnecessary labour and loss of time, but their evil effects are still

more far-reaching, as there is always a tendency to postpone repairs to a

part which involves a vast amount of "stripping " before it can be removed,

and delay in attending to it may result in an engine failure, accompanied

perhaps by considerable damage.

It should therefore be laid down as an axiom of design that every

part of an engine motion; or other part likely to require removal for repairs

in the running shed, is so constructed that it can be taken down by itself

and with a minimum amount of trouble. The attachments of such parts, if bolts

or pins, should be so arranged that there is sufficient clearance to knock

them out, and the position of nuts should be such that they can be conveniently

manipulated with an ordinary spanner. Although it is not possible in all

cases, it will be found generally advantageous to keep nuts in view, that

is facing the operator. Nothing is more exasperating to the shed or shop

fitter than trying, 'probably with a lamp in one hand, to slacken or tighten

a nut which is hidden away in some dark corner, resulting very often in such

ii'uts not being properly secured. Again, we find nuts placed in such positions

that it is perfectly impossible to operate them by means of an ordinary spanner,

or indeed any form of spanner; the only means of lightening them being with

a hammer and chisel, which method is unreliable and destructive to the

nut.

Another small point worth attention is to reduce to a minimum the

number of the sizes of bolts and nuts, and very often the size selected for

these depends more on the passing fancy of a draughtsman than the actual

requirements of the part which they secure. The greater the variety in sizes

of nuts the more spanners the shed fitter has to carry to the job and the

less likely he is to have the one he actually requires.

Many illustrations could be given of inaccessible engine parts, but

the following few will suffice to make my meaning clear:

Piston rod cotters are sometimes so placed that driving them in or

out is a matter of considerable difficulty.

Piston rod and valve spindle cross heads are sometimes. designed

without any provision being made for "starting" them on their respective

rod ends.

Spring link pins or bolts are arranged with no clearance behind to

permit their being driven back when the spring requires removal.

Spring arrangements are so designed that it is necessary to completely

lift the engine to change a spring.

Small internal steam pipes are so arranged as to render their removal

impossible without half stripping the boiler..

I have known cases where it was impossible to take- down parts of

a cylinder cock gear without removing the. whole arrangement.

One most glaring case of ill-considered design came under my notice

not long ago, and although it more particularly affected the shop fitting

staff, I mention it to emphasise my point. In order to remove an engine brake

shaft, it was necessary to take down with it the supporting brackets which

were placed inside the frames. An arm on one end of the shaft which was shrunk

on had to be heated and removed before one of the brackets could be disengaged

from the shaft. When the shaft journals were turned ups. one bracket was

placed in position and the arm shrunk on again and the whole arrangement

had then to be lifted up bodily and the brackets bolted in position.

The remedy was, of course, to make the brackets with removable half

bearings.

I feel I owe the members an apology for somewhat labouring this point,

but I plead its importance as justification. I only wish it was a recognised

part of the curriculum of every draughtsman engaged on locomotive design

to spend about six months as a running shed fitter. [bold added by KPJ]

He would at least learn by bitter experience how, some things should not

be done.

The capability of a new engine to easily perform its appointed duty,

and with a good margin of power to spare, is probably looked upon by the

driver as the point of para— mount importance in a new engine,

but this is a question of fundamental design. and altogether outside the

scope of this paper. He will also proceed to criticise the engine from the

point of view of general convenience, both on the footplate and elsewhere,

and also as regards the accessibility of the parts in which he is specially

interested.

Now I may say at once that I do not believe it is possible to be

certain that any new arrangement of a foot-plate and boiler front will be

satisfactory if decided by means of a drawing only. No matter how much care

is expended in plotting the positions of various mountings, it will be found

when the engine is built that slight alterations here and there would have

made a much more convenient and practical foot-plate.

The shape of the regulator handle, the height and shape- of the cab

windows,, the positions of injector steam valve handles, the brake application

handle, the fire-hole door handle, etc., etc., are all points which considerably

affect the convenience of the driver and are therefore worth a good deal

of consideration.

In order to settle the best and most convenient position for these

details, I suggest the advisability when a design for a new class of engine

is being prepared, of constructing a full-size model of the cab and boiler

front which can be- very cheaply built up of wood and canvas. All the various

mountings, or if- these are not available, rough models of them can then

be placed in position and moved about untir each is most conveniently located.

When this method is- adopted, it is surprising to find how many slight

alterations. are desirable, and even necessary, no matter how carefully the

original drawing has been thought out. For instance, the movement backwards

or forwards a few inches of the- reversing wheel and bracket, or lever and

sector, as the case may mean all the difference between a driver having to

stand comfortably or uncomfortably at his post on the footplate. In the case

of a tank engine it is desirable to make a model of the boiler, side tanks

and coal bunker in addition to the cab, to insure that the tanks do not unduly

interfere with the outlook from the foot-plate. The model should, of course,

be erected at the working height above ground level when it will be found

not only useful for the- purposes above mentioned, but also for determining

the- best position and shape of foot-steps, hand-rails, tool boxes,

etc.

When such a model is completed, I make it a practice- to invite a

few of the leading drivers to inspect it and freely criticise the arrangement

of the details, and I have never yet failed to obtain from them some sound

practioal suggestions as regards minor alterations.

In addition, the running staff feel that their convenience and comfort

is being considered and their practical experience made use of.

The trend of modem steam locomotive design.

Proc. Instn mech. Engrs,

1928, 114, 465-77.

Significantly the author favoured 3-cylinder designs, 4-6-0s and 4-4-0s:

Lecture delivered before the graduates' section in London on 26th March 1928,

and repeated in Birmingham on 13th April 1928.

Discussion on other's work

Armstrong, J.C. Pulverised fuel locomotives.

J. Instn Loco. Engrs., 1929,

19, 86-90. (Paper No. 239).

Maunsell added some Presidential comments on the SR purchase of AEG

equipment for experimental use having observed that:

coal in pulverised form can be burnt in a locomotive without any extensive

alteration being made to the boiler or firebox.

coal of a lower quality than possible to use for grate firing, can be used

in pulverised form.

economy can be effected by the purchase of small coal and slack, which is

really better adapted for pulverising purposes than the large coal that is

necessarily used for grate firing.

when pulverised fuel is used, boiler pressure can be better maintained, and

more finely adjusted to suit varying conditions of road and load than is

possible in a grate fired boiler.

Throughout the run at which he was present, the niasiniuni variation in pressure

was 71bs., which occurred when the train entered a gradient of 1 in 130,

the weight of the train being 1,300 tons, and when the fuel feed was adjusted,

full pressure was quickly obtained. Throughout the remainder of the run the

finger of the pressure gauge practically remained steady on the point of

maximum boiler pressure.

there is no spark throwing, and very little smoke when pulverised fuel is

used.

the quantity of ashpan and smokebos refuse is negligible.

Gresley, H.N. High-pressure

locomotives. Proc. Instn mech. Engrs., 1931, 120, 101-35.

Disc.:135-206

Page 140 Maunsell commented on smoke deflection

Wagner, R.P. (Paper No.

253)

Some new developments of the Stephenson boiler.

J. Instn Loco. Engrs., 1930,

20, 5-21. Disc.: 21-47.

Maunsell (22-4): "I have endeavoured to make a comparison between

the ratios which Herr Wagner has recommended and those which have been adopted

in the most recent engines I have built for the Southern Railway. Although

the ratios are not quite what Herr Wagner advocated, 1: 400, I can only say

that the engines steam well, they are reasonably economical in fuel, and

the back pressure is low, but not so extraordinarily low as the figures obtained

by Herr Wagner in the engines which he has recently designed. Perhaps the

results I have obtained might prove, to a certain extent, the truth of the

old saying, that there are more ways of killing a dog than by choking him

with butter! There is, however, one point which has an important bearing

on the velocity of gases through the boiler flues and back pressure, namely,

the diameter of the exhaust pipe. I sould be glad if Herr Wagner would be

good enough to tell us how that is considered, when calculating the areas

of the ordinary smoke and superheater flues? We have also found from practice

that the relationship between the position of the blast pipe nozzle and the

horizontal central line of the tube plate, measured both longitudinally and

vertically, has a very distinct bearing on the uniformity of the flow of

gases through the tubes; and I would value Herr Wagner's opinion on that

point also.

In the earlier part of his Paper Herr Wagner referred to steel and

copper fireboxes. I can only say that steel fireboxes have not proved a success

so far as I know in England, when applied to engines designed for main line

service. There have been several cases of small shunting engines with steel

fireboxes which. have given satisfactory results, but not with engines designed

for main line serdce. I do not believe that the failure is due to the poor

quality or the unsuitability of the material which is used. Some years ago

I imported from America a number of steel firebox plates, and the results

obtained with these were no better than the results obtained from plates

made to a similar specification, but manufactured in England. My opinion

is that the failure was due to the fact that the fireboxes of British engines

are relatively small compared with American engines, due to weight and clearance

restrictions, and the rate of combustion per square foot per grate area is

relatively high; and, in addition to its higher conductivity, a copper firebox

will stand up better to high temperatures and severe conditions of service

than a steel firebox. I remember, when going through the Baldwin Locomotive

Works, discussing the question of the steel and copper firebox with Mr. Sam

Vauclain, the President, and asking him if he ever fitted 1ocomotives with

copper fire boxes? Mr. Vauclain said, as far as he could remember that the

only boilers to which he had fitted copper fireboxe were those which were

intended for use in Cuba and, he added, with a twinkle in his eye, that he

thought probably the reason for doing so was the very low mentality of th

natives who would have to operate the engines in that island! I did not think

that remark was exactly a flattering one to European engineers. We shall

certainly watch with interest the performanc, of the corrugated box, which

Herr Wagner has illustrated though I am not quite sure how that is going

to get himout of the trouble experienced with tube plates. The corrugation

of the side and crown plates may possibly tell him with regard to expansion;

out I do not see how he is going to be relieved of the tube plate

trouble.

compiler.

The question of locomotive sheds : Report No. 1 (Great Britain, Northern

Ireland, India, Dominions, Proctectorates and Colonies): Subject VI for

discussion at the 10th Session of the International Railway Congress Association,

London, 1926. Bull. int. Rly Congr. Ass., 1925, 7, 501-70 +

2 folding plates. 4 illus., 22 diagrs., 4 tables, 10 plans.

The question of locomotives of new types; in particular turbine

locomotives and internal combustion motor locomotives: Report No. 2. (British

Empire, China and Japan): Subject V for discussion at the 11th Session of

the International Railway Congress Association. Bull. int. Rly Congr.

Assn., 1929, 11, 1563-71. 3 diagrs. (s. & f. els.).

2 tables.

Survey based on questionnaires.

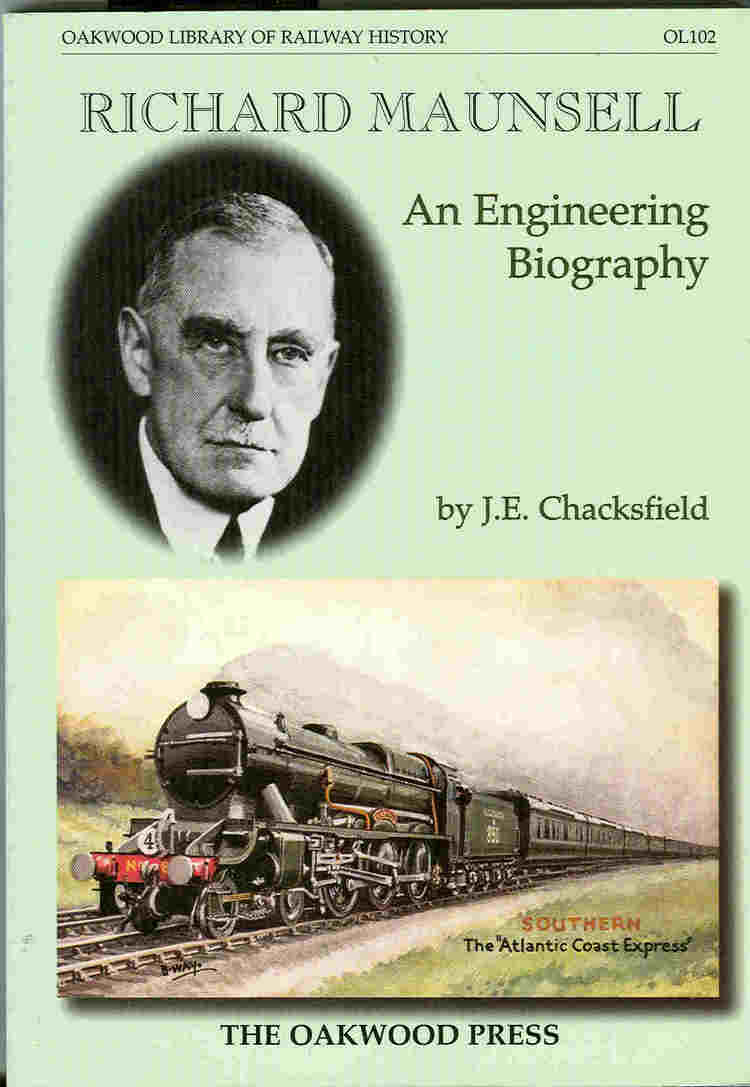

Biography

According to Chacksfield Maunsell

was born on 26 May 1868 in Raheny, County Dublin, Ireland and was educated

at the Royal School in Armagh and at Trinity College, entered 1886.

Day-Lewis noted that: "He was born a member

of the British ascendancy in Dublin, the son of a leading solicitor in the

Irish capital, and unlike Bulleid he always felt a strong vocation for railway

work. His father wanted him to go in for the law, but said that he could

join the railways if he still wanted to do so after taking his degree. Maunsell

accordingly graduated at Trinity College and at once applied to become Ivatt's

first pupil at Inchicore [in 1888]. After a three year course with the Great

Southern and Western of Ireland he completed his training under the admirable

J.A.F. Aspinall at the Horwich Works of the Lancashire and Yorkshire Railway

– the course also adopted by Gresley and Henry Ivatt". He was latterly

flocomotive foreman at Blackpool (Locomotive obituary)

He went out to India in 1894, but his stay in the east was short and, having

reached the post of district locomotive superintendent at Asansol (East Indian

Railway) he returned to his old works at lnchicore as.works manager, becoming

locomotive superintendent of the Great Southern & Western Railway in

1911. Some further biographical material has been published by

Atkins in Backtrack, 11,

396.

In December 1913 he was selected to succeed the

H. Wainwright as chief mechanical engineer of

the South Eastern & Chatham Railway. When that line was incorporated

in the new Southern Railway, Maunsell became Chief Mechanical Engineer

(Locomotive Mag., 1923,

29, 220) of the latter [KPJ Note tardines s in appointment],

retiring in 1937. He was an excellent administrator, and appointed subordinates

to whom he could delegate much of his work.

Nock (The Southern King Arthur

family) notes that he had sought the advice of Joynt on the valve

gear for the L class. Later his designs owed much to

H. Holcroft , J.

Clayton , and G. H. Pearson, all admirers of

Churchward. With these assistants, it is not

surprising that Maunsell was the first to apply Churchward principles outside

the Great Western Railway. His very successful N class mixed traffic 2-6-0

not only imitated a Great Western wheel arrangement but also incorporated

the Churchward variation of the Belpaire firebox, tapered boiler, and long

travel valves, together with the un-Churchward feature of high-temperature

superheat. The success of this locomotive induced Maunsell progressively

to introduce variations of the basic layout; some of his subsequent 2-6-0

types had three instead of two cylinders, or 6ft instead of 5ft 6in. driving

wheels. His 'River' class 2-6-4T, to the same basic design, was less fortunate.

Engines of this type had to be rebuilt as 2-6-0 tender machines after they

had shown a dangerous tendency to derail at speed, although tests which Gresley

carried out at the request of the SR management showed that it was Southern's

tracks rather than Maunsell's locomotives which were at fault

. See also references to WW1 activity

in paper by L. Simpson...

For heavy passenger work Maunsell modified the draughting and increased

the valve travel of an existing London & South Western two-cylinder 4-6-0,

thereby creating the 'King Arthur' type, perhaps his most successful locomotive.

For greater power output he also built sixteen units of his four-cylinder

'Lord Nelson' type 4-6-0. His famous 'Schools' class 4-4-0 had three cylinders

and used the components of the 'Lord Nelson' and 'King Arthur' types. It

was a fast-running, powerful machine, its lack of adhesion weight offset

by a smoother torque (see Holcroft's 1918

paper on three cylinder designs). Maunsell having adopted for the Lord

Nelson and Schools Holcroft's proposal for cranks set at 135 degrees,

giving eight exhausts per revolution with four cylinders and six with three

cylinders. Forty Schools were built ; this was a large number by Southern

standards, for electrification was steadily reducing the number of busy steam

routes. The SR being primarily a passenger railway, passenger and mixed traffic

designs could take care of most requirements, but Maunsell did build a handful

of freight tank locomotives: a three-cylinder 0-8-0T for shunting and a 2-6-4T

for transfer work. His last design was an 0-6-0, the Q class.

Cocks noted that at the grouping, Maunsell laid down a set policy

(these precepts had been established in his Presidential Address (above))

for the future design of locomotives, under the following headings:

(1) Ample power for all requirements to enable sectional timing

to be maintained with a high degree of efficiency.

(2) Ease of maintenance.

(3) Suitable for operating on all three sections within the limits of bridge

loading.

(4) Standard locomotives with as few types as possible to cover the whole

of the requirements. Standard details to be as interchangeable as possible,

such as boiler, cylinder, motion, tyres, axles, axleboxes, fittings and boiler

mountings.

(5) Belpaire type firebox, with grate area and heating surface well

proportioned.

(6) Long lap piston valves.

(7) Freer exhaust passages.

(8) Accessibility of all parts ("Make everything 'Get-at-able.' was Maunsell's

remark).

(9) Footplate comfort and ease in handling. In this connection wooden models

or mock-ups of the cab with the handles for operation in position were made

for the enginemen's inspection and suggestions.

(10) Lubrication of all parts to be efficient and simple. To be under the

control of the enginemen as far as possible without leaving the footplate.

(11) Large smokeboxes and capacious ashpans.

The relationship between Maunsell and the Locomotive Running

Superintendent (A.D. Jones) has failed to

receive adequate coverage, although it is mentioned by Nock.

On the carriage side Maunsell introduced the buckeye coupling for

the mainline (non-electric stock). Only corridor stock was constructed for

steam services: see Gould. Many of the later

portraits of Maunsell show a very frail-looking person who clearly suffered

from ill-health. Nock (Great locomotives

of the Southern Railway) notes on page 93 that Maunsell was a fine

cricketer. Locomotive Mag.,

1935, 41, 51 notes that he was elected Chairman of the Railway

Clearing House Chief Mechanical Engineers Committee for 1935...

Day Lewis summarised Maunsell's

abilities: "Though a perfectly sound engineer he was a hustling administrator

rather than a designer. He was always respected but his mercurial, irascible

temperament gave him the reputation of a Tartar. Like Gresley he was happy

to surround himself with talented subordinates, the sort of men who in

pre-grouping days would have probably found a department of their own. But

unlike Gresley he inherited no great tradition and was free to look around

£or the best examples of locomotive practice then available. Thus his

team had a strong flavour of the Midland, together with the Great Western,

Swindon and Churchward."

See: J.E. Chacksfield:

Richard Maunsell: an engineering biography.

Atkins, Philip. An Inchicore

threesome. Backtrack, 1997, 11, 396-9.

S.C. Townroe, The Arthurs, Nelsons, and Schools of the Southern

(1973);

O.S. Nock, Locomotives of R.E.L.

Maunsell (1954);

H. Holcroft, Locomotive Adventure

(n.d.);

Nock, O.S. Railway enthusuast's

encyclopedia

Appointment as CME SECR in 1913: see

Loco. Mag., 1913, 19,

274 with photographic portrait

Appointment as CME Southern Railway in 1923: see

Loco. Mag., 1923, 29, 245

with photographic portrait reproduced above

The late Mr. R.E.L. Maunsell, C.B.E.

Locomotive Mag., 1944,

50, 52

See Atkins, Philip.The fruitless

quest. Rlys South East, 1992, 3, 62-7. (the quest for a

larger "boat train" locomotive)

Updated: 2021-01-13

Return to Steamindex