|

[Sir] Henry

Fowler

Anderson and

Lemon

Chacksfield has

written an extensive, but not authorative, biography of Fowler which concentrates

excessively on his many, and varied, external activities, rather than on

his great contribution as an engineer: partly because the Author has clearly

failed to read what Sir Henry wrote and spoke about.

Fowler's Presidential Address

to the IMechE in 1927 should be read by all who have sought to assess

both Sir Henry's and George Stephenson's stature as engineers :it may also

imply much on the gross incompetance of the management of the LMS that such

a great engineer became entwined in an environment which failed to perceive

this and encourage its development. On the LNER Whitelaw ensured that a

comparable man of genius, Gresley, developed his full potential in spite

of a far weaker corporate financial structure.

Ellis in his book on the Midland

Railway brought into question the extent to which locomotives could

be attributed to specific engineers. Firstly, he cited James Holden of the

Great Eastern "who was an excellent man for carriages". His most famous

locomotive designs, including the Claud Hamiltons and the great Decapod,

were made for him by the late Fred V. Russell, who also produced the Great

Eastern 4-6-0s officially ascribed to Stephen Holden. Ellis then stated:

"What all this is leading up to is the question of whether H Fowler of the

Midland ever designed a locomotive. He is reported as having once said, after

dining, that he never did such a thing in his life. Only two really new designs

appeared from Derby during the last years of the Midland Railway, one a banking

engine for the .Lickey incline, and the other a heavy goods for the Somerset

and Dorset." The Ellis remark is liable to be misunderstood: firstly the

"after dining" might imply inebriation, but Fowler was a teetotaller, and

secondly it might be thought that he was totally uninterested in locomotive

design and this was obviously not the case: indeed one suspects that no other

mechanical engineer was as interested in locomotives, especially their boilers,

as Sir Henry..

Fowler's qualities as a mechanical engineer were vastly greater than

those of Collett, and one can be certain that like Webb, Fowler has suffered

from glib assessments. Cox's paper to the Institution of

Locomotive Engineers is especially important for the LMS period.

He is also included in Marshall. The

gaps (2011) arer still being filled: note John F. Alcock's attribution of

the pioneering work on diesel locomotives to

Fowler.

|

Michael Rutherford's The era of

Sir Henry Fowler. (Railway Refections [No. 33]). Backtrack, 1997,

11, 501-9. examined Fowler in the usual Rutherford style. Several

sources are listed which fall outside the period covered by

Jones, notably an appreciation by Baldwin,

and an important paper by James Clayton. On the other hand it was written

prior to Chacksfield's biography. "Direction

in new design, if it came, was more by accident and lack of interference

than by purpose. It certainly didn't come from Fowler. The Garratts (Anderson's

variant) were an example of where the CME should have put his foot down..."

The illustrations include Sir Henry Fowler in Scout uniform with Dr H.H.Bemrose

Scout commissioner for Derbyshire at the naming of Boy Scout.

There is a remarakable comment by Sir Henry on "the

disgraceful state" of the nation's roads whether for cyclists or for light

motor cars in his contribution to Robson's paper on steam

lorries.

See also Fowler locomotives

Patents

with James Edward Anderson

2445/1911 Improved automatic control of dampers for superheaters

in locomotive and other boilers. Applied 13 June 1911 Accepted 10 August

1911.

2446/1911 Automatic control for cylinder bye-pass valve on locomotive

or steam engines. Applied 31 January 1911. Accepted 26 October 1911

12884/1911 Improvements in steam superheaters. Applied 23 May

1911. Accepted 22 February 1912.

with William Chatterton

16533/1912 Improved fire extinguisher. Applied: 15

July 1912. Published: 17 October 1912

Own papers: this list is still incomplete

(mainly due to the dominant agrarian nature of Norfolk): there are further

incomplete references to papers by Fowler presented to the Institution of

Civil Engineers in 1897 and in 1922 and to the Institute of Metals in 1933,

and to the Faraday Society in 1921.

Calcium carbide and acetylene. Min.

Proc. Instn Civ. Engrs., 1898, 134, 1-33. Discussion:

24-65.

Paper awarded Telford Premium

Chisels. Engineering, 1916, 101, 195.

Midland Railway specification.

Chisels. Proc. Instn Mech.

Engrs, 1916, 90, 141-5. Disc.: 145-82.

Consumption of fuel in locomotive practice. Engineering, 1930,

130, 380. Bibliog.

Abstract of a British Association (Bristol 1930) paper .

Effect of superheated steam on non-ferrous metals used in locomotives.

Engineering, 1922, 114, 374.

The electrification of English main line railways.

Proc. Instn mech. Engrs.,

1922, 102, 317-30.

A discussion meeting chaired by Sir Henry Fowler. Concluding, Sir

Henry welcomed the pertinent points raised by Dr. Kapp. There were many points

with regard to the criticism of steam and electric locomotives which might

be dealt with if there was time, but the consideration they wanted to lay

hold upon was whether it was going to pay to electrify our main lines. There

was no insuperable electrical or mechanical difficulty in the electrification

of main lines, but there was a difficulty in regard to the financial side

of the problem when they were dealing with a low density of traffic. He would

again quote his friend, Mr. A.W. Gibbs, who said the difficulties were more

mechanical than electrical. The electrical side of the problem seemed to

be perfectly sound. There were certain mechanical difficulties. One of them,

unfortunately, had not been touched upon, that was the question of low centre

of gravity and wheel arrangement.

Fractures in locomotive boiler tubes. Engineering, 1921, 111,

466-7.

Latest types of steam and internal-combustion locomotives [in:] Institution

of Civil Engineers Engineering Conference, 1928. London, Institution of Civil

Engineers, 1928.214 p.

with Gresley, H.N. Pp. 147-52 (Disc.; 152-68):

a general survey.

Lighting of railway premises: indoor and outdoor.

Proc. Instn mech. Engrs.,

1906, 865-906. Disc.: 906-41.

Presented when he was Gas Engineer at Derby. Includes arc lighting, oil lamps

and gas lighting; the use of a portable photometer for assessing lighting

in passenger stations; the cost of gas mantles; fuel consumption; the use

of incandescent electric lamps; and the problems of lighting goods yards,

locomotive sheds and workshops. Hughes, his former chief, contributed to

the Discussion (pp 917-20)

Locomotive boilers. Rly Engr, 1924, 45, 81-5; 117-23; 179-83;

237-40; 301-5, 427-31. illus., 53 diagrs., 2 tables.

with Symes, S.J.

Locomotive brasses and bronzes. Metal Ind., 1922, 20, 461-2.

Effects of superheated steam.

Locomotive railway traction. Engineering, 1935, 139, Silver Jubilee

Section (May 3rd) p. 32 + plate p. 28.illus.

A general survey of the period; 1910-1935.

Locomotive repairs. J. Instn Transp., 1929/30,11

,59-66; 73-89. Disc.: 67-72. 6 illus., 3 tables, 11 facsim. forms.

The Derby "progressive" system of locomotive repair. Noted that probably

the most important work done on the mechanical engineering side of a railway

is the maintenance of locomotive stock in an efficient condition..

The maintenance and repair of locomotives.

Trans. Instn Loco. Engrs,, 1913,

3, 1-15. (Paper No. 14)

Address by the President without discussion: boilers received the

most treatment and were regarded by the speaker of being of primary importance.

Topics examined included pitting and corrosion, burning of the firebox and

expansion/contraction which led to grooving. Wear of the motion and cylinders,

wheels and axles and boiler mountings were also considered.

Metallurgy in relation to mechanical engineering.

Proc. Instn mech. Engrs.,

1922, 102, 331-5.

with H.S. Hele-Shaw

Some notes on production: Presidential Address. Proc. Instn Automobile

Engrs, 1920, 15, 6-31.

Mainly the application of the Midland Railway's mechanized accounting

and stock control techniques. Thomas Clarkson, the retiring President observed:

"I feel particularly happy in retiring from the Presidential Chair knowing

that Sir Henry Fowler has taken my place, because I am sure that the Institution

could not ba piloted by a better man than by Sir Henry Fowler, who has by,

sheer merit and ability won for himself a very high place in' British

engineering, and he occupies the position, as you know, of Chief Mechanical

Engineer to the Midland Railway Company."

Address by the President.

Proc. Instn mech. Engr,

1927, 113, 723-47.

Two themes were intertwined: the significance of George Stephenson

and the significance of metallurgy on mechanical engineering. "I have always

been impressed by the fact that George Stephenson seemed to be not only

conversant with, but an expert on all that was known and of interest concerning

mechanical engineering in his day." "In 1848, Dr Pole translated, from the

German, Alban's book on a high pressure boiler, which was in fact an interesting

water-tube boiler" (running at 1000 psi). "I have always been impressed by

the fact that George Stephenson seemed to be not only conversant with, but

an expert on all that was known and of interest concerning mechanical engineering

in his day." Standardizing materials: (steels, brasses, bronzes); steel

manufacture, metallography, fatigue, radiology, education and higher

pressure boilers. Several quotes from Ecclesiasticus: "They will maintain

the fabric of the world; and the handywork of their work in their prayer."

Aspinall gave the Vote of Thanks pp 746-7.

Railway carriage lighting in

Railway mechanical engineering: a practical

treatise by engineering experts. London, Gresham, 1923. Volume 1:

261-90.

Considers lighting with oil gas before turning to electric lighting.

Even lighting by rape seed oil is considered.

The recent development of the steam locomotive and its future aspect. Proc.

Wld Engng Congr. (Tokyo), 1929, 15, (3), 1-15. Disc.: 16-18. 11

diagrs. Bibliog. (Paper No.253) .

A world survey of locomotive development with the topics of high pressure

boilers and turbines accentuated .

Solid crank axles. J. Instn Loco.

Engrs, 1925, 15, 130-43. Disc.: 143-55; 323-34. illus., 6.diagrs.,

2 tables. (Paper No.177).

Results of metallurgical research carried out by H.A. Treadgold under

Sir Henry Fowler's supervision.

Steels for locomotive purposes. J.

Instn Loco. Engrs, 1922, 12, 106-27. Disc.: 127-33. (Paper

115).

Superheating. Proc. Instn mech.

Engrs., 1921, 101, 649-52.

with John Dewrance

Superheating steam in locomotives.

Proc. Instn civ. Engrs., 1914, 196:

extract below

Transport and its indebtedness to science. Engineering, 1923,

116, 377-80. diagr. Bibliog. (footnotes).

Abstract of a( Liverpool 1923) British Association paper .

Discussion at:

International Railway Congress Association. 11th Session, Madrid, 1930. 2nd

Section. Question 5. Locomotives of new types. Bull. int. Rly

Congr.Ass., 1931, 13, 97-8.

Comment on the operating costs of the Ljungstrom turbine

locomotive

International Railway Congress Association. 11th Session, Madrid, 1930. 2nd

Section. Question 6. Improvements in the steam locomotive. Bull. int.

Rly Congr. Ass., 1931, 13,115.

Notes on the savings which resulted from the equipment of the

Claughton class with Caprotti valve gear.

Fowler as compiler

The question of reduction of the cost of traction: lubrication of axlebox

for all rolling stock: Report No.3 (British Empire) : Subject 4B for discussion

at the 10th Session of the International Railway Congress Association, London,

1926. Bull. int. Rly Congr. Ass., 1925, 7, 313-87 .8 diagrs.,

10 tables.

Review based on questionnaires.

Discussion on other's papers

Armstrong, J.C. Pulverised fuel locomotives.

J. Instn Loco. Engrs., 1929,

19, 90-2. (Paper No. 239).

Sir Henry opened the discussion with some rather penetrating comments:26

years ago, his then chief, Samuel Johnson, sent him to look at a boiler in

London whicli vas fired by pulverised fuel, having in his mind the question

of its adaptation for locomotive purposes. There was trouble with this boiler,

owing to the fact that thc basic slag, which was formed badly, corroded the

firebrick which lay in the furnace–this is a trouble with all boilers

using pulverised fuel, although Armstrong has not mentioned it. In one of

the boilers which he had seen in Germany using pulverised fuel, very little

firebrick was used, but hr believed the difficulty had been met by arranging

a very large number of burners vhich gave a short flame. One of the greatest

difficulties in introducing powdered fuel in connection with electric light

plants has been due to this particular point, even uhen some of the combustion

chambers were of very large size. The difficulty experienced with a powdered

fuel 1ocomotive used in America was similar and overcome by the use of very

short flames.

Dewhurst, P.C. British and American locomotive design and practice:

some comparative comments thereon from practical experience. 375-423.Discussion:

424-511. Proc. Instn Mech.

Engrs., 1922, 102, 426-

said it was a matter of some difficulty to discuss a Paper of this

kind, but he felt that the presentation of it was of very great advantage,

more particularly to the junior members of the Institution interested in

locomotive work. The Paper gave in a concise form what he thought Lieut.-Colonel

Kitson Clark would agree with him would take a lifetime under ordinary conditions

to get together. He was placed in somewhat of a difficulty because he had

not quite appreciated whether the Author had proposed to bring forward the

difficulties which he had experienced with locomotives built in accordance

with English and American practice, or whether he proposed to discuss the

differences in locomotive practice in these two countries. He raised two

points which were always in the minds of locomotive engineers when dealing

with design in thiscountry-the loading gauge and the weight on the bridges.

Those things did not press to anything like the same extent in America that

they did here. As far as the bridges were concerned, the Author said it was

quite an easy matter to deal with the question of bridges if the money saved

in using larger and heavier locomotives was capitalized. He himself had travelled

lengths of 200 or 300 miles on various lines in America, going over perhaps

a dozen bridges across streams but practically never a bridge over a public

road. Engineers in this country were constantly meeting the difliculty of

bridges over roads. With reference to the use of ten-wheel engines, the Midland

Railway, of which he was the Chief Mechanical Engineer, was the only one

that had a ten-wheel coupled engine running on a main line, and in a distance

of two and a half miles that railway ran over road bridges-not large bridges-and

the locomotive had to be designed to suit those particular bridges. It was

a point to consider that in this country the number of bridges were intense

and immense. With regard to wagons, the question of increasing their size

was always in the minds of railway engineers in this country. The remedy

largely lay with the owners of wharves and coal screens, etc. Taking the

capital value of making the necessary alterations, it would be found to be

an immense sum. The first President of the Institution, George Stephenson,

was such an artistic man that he put a little crown or ragged piece of tin

work on the top of the “Rocket,” probably, but for this the head-room

would now be even less. It was only possible to touch very lightly on the

details of the Paper, and practically speaking an evening might be devoted

to almost every one of the points mentioned, and several evenings on those

not mentioned. The question of outside cylinders was an important one, and

the Author showed that they were practically universal in American locomotives.

In the majority of Colonial countries there were no platforms. One of the

things with which the railway engineer had to contend in outside cylinders

was coming within the gauge. Every engineer would like to have a larger boiler,

and he advocated very strongly that the best way to burn coal was to burn

it fairly slowly, not intensely, not with a blast that carried a very large

proportion of the fuel through the tubes into the smokebox- if it went no

further-and there again came up the question of weight. He held that there

was no more efficient way of using steam in a locomotive than in using it

in a compound and with superheat. The question of basic versus acid steel

he felt was not a question of basic or acid, but a question of how the basic

steel was made. If an engineer could be perfectly satisfied with the way

in which it was made, there was no difficulty at all in using basic steel

for any purpose, and the way in which it was made included of course the

material. He would like to satisfy Colonel Kitson Clark with regard to the

question of how basic steel could be flanged. On the railway with which he

was connected, they had recently taken a plate shaped somewhat as shown in

Fig. 12, the distance at A being 45 inches. It was not a thick plate but

it was flanged into a splasher with quite a sharp corner, and the distance

at B was 16 inches. He thought that should be conclusive proof that there

was no difficulty in flanging basic steel. The thickness undoubtedly made

a difference. They were able to flange the cross-stays and other parts made

of basic steel up to 2 inch in thickness, with ease.

With regard to the use of copper and steel in fire-boxes and tubes, he had

just had an opportunity of seeing about half a dozen steel boxes which were

put in during the War, and he stated without hesitation that he did not wish

to use steel fire-boxes on his railway. It might be that it was the condition

in which the coal was burned or the coal itself, but the whole of the lower

portion of the boxes would have to be scrapped much earlier than they would

have been, had they been copper. With regard to the erosion which took place

in copper tubes, he could say from an experience of between 2,000 and 3,000

locomotives that there was no difficulty at all, but when his Company and

certain other companies used brass tubes there was considerable erosion just

inside the tube-plate with certain coals. His Company had used during the

War a large number of steel tubes, but replaced them as soon as ever an

opportunity occurred, the reason being that the copper tubes gave infinitely

less trouble. He had gone through month by month the casualties due to leaky

tubes, and in spite of the fact that there were three times as many copper

tubes in service as there were steel tubes, he thought the casualties were

ten to one on the other way round. With reference to fusible plugs, the Americans

had evidently considered the matter of sufficient importance to get the National

Bureau of Standards to make an investigation into the subject. He knew it

was not universally held amongst his colleagues in this country that a fusible

plug was exactly the right thing. Such a plug must be properly made and looked

after, and he thought even if a fusible plug had anything happen to it, at

all events the attention of the firemen was called to the fact that there

was something happening. Since the Midland Railway had adopted the principle

of filling the plugs, and re-heating them in a muffle to just above the melting

point of lead, the difficulties had disappeared. The Author also dealt with

the somewhat complicated question of the superheater elements and the headers.

On the Midland they used with advantage a copper ring of diamond section

fitted into grooves both in the header and in the collar on the superheater

element. He thought there was a great advantage in a loose flange over a

fixed flange which rigidly connected the superheater elements as used in

many cases. The shrinkage of tyres mentioned by the Author was employed by

certain railway companies. The allowance given by the Author was 1/750, whereas

his company employed 1/1100. That was very largely dependent on the finish

obtained on the tyre and the centre. On a rough centre a greater shrinkage

was required than with a smooth one. When his predecessor came back from

America some years ago, he was very delighted with the system of lubrication

in which a mixture of waste and horsehair was used. It was given an extended

trial, but there was difficulty from the fact that the horse-hair tended

to get into the oil channels and curl up into small balls.

With regard to oil consumption, in this country, with mechanical lubricators

under the axle-boxes, it had been possible to reduce the consumption 66 per

cent on what the Author mentioned. He was in the position of having to look

after not only Belpaire boilers, and boilers with roof bars, but also round-top

boilers with direct stays, and he was just dealing with the question of replacing

direct-stayed boilers with boilers of the Belpaire type

Fry, Lawford H. Some experimental results from a three-cylinder compound

locomotive. Proc. Instn Mech.

Engrs., 1927, 113, 955-61

Sir Henry commented on the performance of three-cylinder compound

locomotives and the Royal Scot classes.

Gresham, J.N. (Paper No. 184 Vacuum

brake ejectors. J. Instn Loco. Engrs., 1925, 15, 335-48. Disc.:

349-63.

Sir Henry Fowler (351): leak tests very dependent upon size and shape

of hole: had collaborated with Gresley on testing. He also noted that with

long trains the dimensions of the pipe were very important. He

also refered to Fig. 4 as it shows how essential it is that the vacuum creating

apparatus, whatever it is, is at the highest state of efficiency. There is

a difficulty getting drivers to understand that there are certain conditions

which allow him, if he will take the trouble, to work very much more efficiently

in maintaining the vacuum. The figures which are given are particularly

interesting with regard to the question of the 15 mm., ejectors. We have

had some experience with them, but:feel that with an ordinary train one is

running pretty near the margin when using them. A vacuum-fitted wagon is

one of the worst offenders as regards leakage, due to the maintenance of

the train pipe. On the locomotive side, care need to be taken in the fitting

of the pipes on locomotives: he had figures which show the very great variation

and losses which one can have even on the locomotive itself, necessitating

a very much larger amount work being done by the ejector which creates the

vacuur owing to the fact of the poor fitting of the pipes.

Gresley, H.N. High-pressure

locomotives. Proc. Instn Mech, Engrs., 1931, 120,101-35.

Disc.:135-206

Sir Henry Fowler (138-9)

commented on other high pressure locomotives, on the oil separator on

the Löffler boiler, and on the chimney and smoke deflectors fitted to

No. 10000

Kelway-Bamber, H. (Paper No. 182). Railway carriage

bogie trucks in service. J. Instn Loco.

Engrs., 1925, 15, 335-48. Disc.: 349-63.292-8. Disc.:

298-310.

Sir Henry (298-301) noted the lack of slipping on Underground trains

between Charing Cross and Strand and wondered if this was due to hot wheels:

tyres became hot in service. He also made observations on the loads on bearings:

7¼ tons on LER as against 19¼ tons on the GIP. Col. Graham (301-2)

noted that the dryness of the Underground system reduced the risk of slipping;

he also made observations on bearing pressures and on brakes acting upon

wheel flanges.

Robson, P.W. Road transport by steam-vehicles.

Proc. Instn Mech. Engrs.,

1920, 99, Disc.: 662-3.

Sir Henry Fowler (662-3) said that, having been the first observer

of a steam-driven lorry which went out on official trial in this country,

at which trials he had the pleasure of meeting a prominent Member of the

Council, he could not help looking back and seeing the great developments

which had taken place in these vehicles since that time. He had been particularly

interested in what the Author had said with regard to electric vehicles,

because he represented a firm which had, he believed, the largest fleet of

this type of motors in the country, which they found extremely useful for

town deliveries. He was sorry the figures which he could put forward, and

which had been published quite recently in Motor Transport, could

not be compared with those the Author had given, because the latter had evidently

been chosen from typical heavy working under good conditions of loading;

these conditions were one of the great essentials for getting the best service

not only out of steam-vehicles but any type of motor, and one which railway

companies had very gwat difficulty in finding. In view of the constant changes

in the rates paid for labour at the present time it would add materially

to the usefulness of the Paper if the Author would state, in reference to

the figures given on page 642, the date to which these figures applied, as

this would be of use for future reference.

With regard to the life of vehicles, his firm purchased two motor vans in

1903 which had only just been disposed of, although for a very considerable

time they ran for twenty hours out of the twenty-four. They had a few

steam-vehicles, one of which had already had a life of sixteen or seventeen

years. A tractor built at Lincoln had a life of about ten years and was still

working satisfactorily. One point which had not been touched upon, but which

was of vital interest from a warehousing standpoint, was the fire risk with

steam-vehicles. That subject had received much greater consideration of late

years than in earlier times, but it was a factor which militated against

the use of steam-vehicles under certain conditions. He was sorry that from

a purely railway standpoint he could not discuss the question which the Author

had touched upon in the early part of his Paper in the time at present at

his disposal. It must be remembered, however, that motor-vehicles at present

ran on a permanent way–the roads–which was practically speaking

free. He lived on the side of a main road between two cities about 60 miles

apart, and he knew the difficulty he experienced in using a push-bicycle

over that road at the present time, and more so with a fairly light car on

four wheels. Undoubtedly this question of roads was a subject which must

be handled before the motor-vehicle could be satisfactorily dealt with on

the lines suggested by the Author, as many of the roads were at present in

a disgraceful state. Until a central authority was established, the roads

would not be put into a condition in which they could be used for steam or

petrol traction to the greatest advantage, and the question naturally arose

as to who was to pay for this. He did not wish to discuss the question of

the new taxation of vehicles, but he thought it would hardly meet the state

of things which the Author laid down as likely to occur in the future.

Sauvage, E. Recent development of express locomotives in France .

Proc. Instn Mech. Engrs.,

1914, 87, Disc.: 416.

Wagner, R.P. (Paper No.

253)

Some new developments of the Stephenson boiler. 5-21. Disc.: 21-47.

J. Instn Loco. Engrs., 1930,

20, Fowler p. 24

Sir Henry Fowler

(24-5): I agree with Mr. Maunsell that the Paper we have

heard requires a great deal of discussion and also a great deal of thought.

To begin with, in the first part of the Paper reference is made to the question

of a corrugated firebox, and no doubt the Author will remember that the Jacob

box of the Santa Fé Railroad of America was on the same principle,

but for various reasons it has been abandoned. In the box with which Mr Wagner

is experimenting, I am rather doubtful whether trouble may not be experienced

owing to the "breathing' which must take place in the corrugations. Something

will probably also depend upon the class of water used, and I think difficulties

may arise with water which gives a hard china-like scale which might crack

along the corrugation and lead to subsequent corrosion.

With regard to the interesting proposal of increasing the number of

superheater elements in the smoke tubes, I would point out that one railway

in England has adopted for many years elements comprised of six small tubes

in each superheater flue tube as against the normal arrangement. On the old

Midland Railway, we have tested an engine so fitted, but it did not meet

with the success we had hoped.

Coming to the main point of the Paper, which refers to the proportions

of the tubes, one can compare the suggestion of Mr. Wagner of area of free

space to area of surface of tube with that of Mr. Lawford Fry, who has, as

is well known, done such a great work on the proportions of the ordinary

boiler tubes, and who advocates that the ratio between the diameter of a

tube and its length should not exceed 1 to 100, and it is interesting to

note that in the case of a plain boiler tube, if the ratio A /S is 1 /400,

as recommended by Mr. Wagner, this is identical with Mr. Lawford Fry's proposed

maximum ratio mentioned above.

I would like to know how the figures on Fig. 9 were obtained, because

they are of very considerable interest. It is also interesting to see the

efficiencies which Mr. \Vagner has given, for after all, one's own children

are always much better looking than anyone else's, and I would like to say

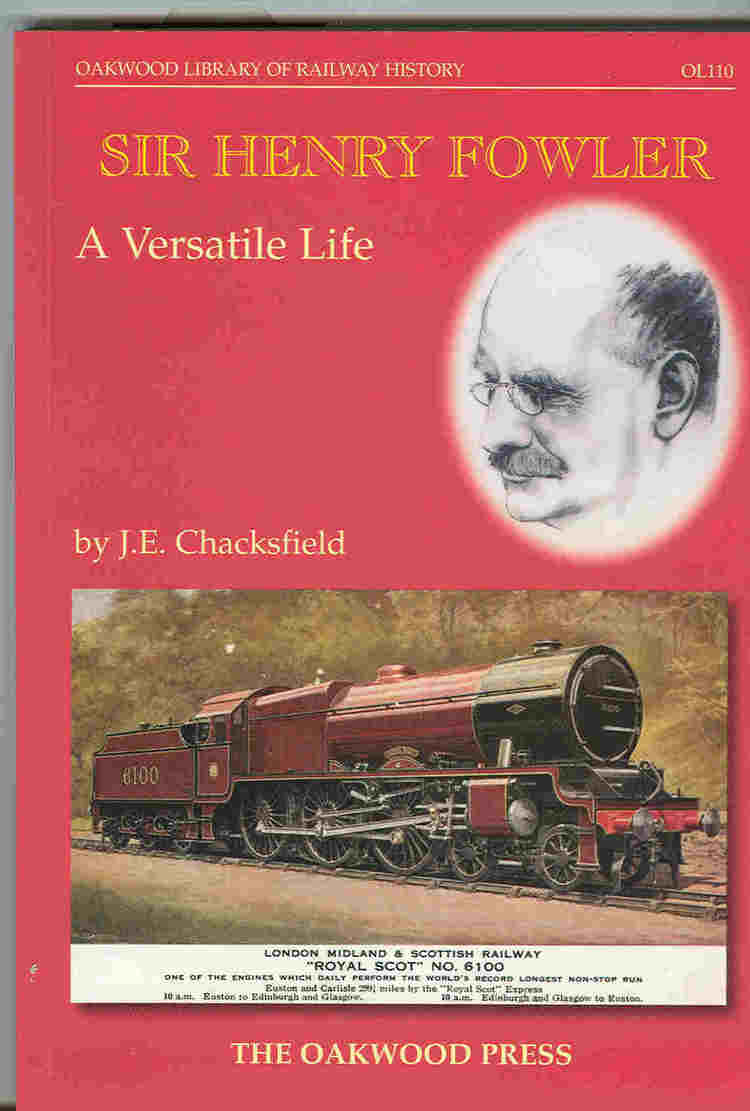

that on my Company's "Royal Scot" engine, on a run in which we reached l,300

drawbar h.p. and an average speed of about 52 miles, the average boiler thermal

efficiency is found to be 80½ per cent.

I have made a tabulated list (see abstract of paper) of boiler proportions

which are looked upon as fairly satisfactory and efficient. The manufacturing

question comes in with regard to the first three, because they have the same

tube plate. We look upon the first boiler; G.7, as probably being the best

proportioned one, and it will be seen that the ratios for it vary considerably

from those according to Mr. Wagner's proportions.

I have also taken the ratio of internal diameter to length for one

of the boilers guoted by Mr. Wagner and I find that this ratio is 1 to 112,

somewhat in excess of Mr. Lawford Fry's maximum. I would, however, say that

I am not at all in favour of tubes 22 feet in length and of the diameter

given.

Biography

This is based on A.F. Cook, Radford. Baldwin and

Westwood (and in part on Chacksfield).

Fowler was born at Evesham, Worcestershire, on 29 July 1870. His father,

Henry, dealt in furniture, including antiques. The family were Quakers. The

family enjoyed rowing and celebrated Christmas by swimming in the Avon. He

was initially educated at the local Grammar School and then attended Mason

Science College, Birmingham, between 1885 and 1887 and studied metallurgy

under Professor T. Turner. He served an apprenticeship under J.A.F.

Aspinall at Horwich from 1887 to 1891. He then spent

four years in the Testing Department, working under G.

Hughes, whom he succeeded as chief of the department.

From 1895 to 1900 he was Gas Engineer of the LYR, transferring to the MR

in the same capacity in the latter year.

He was a strict teetotaller, extremely energetic being involved in

football, cricket and hockey. He could keep goal or wicket with equal facility.

In his spare time he devoted much of his time to the Boy Scout movement,

being also keen on cycling and the collection of coins and medals.

Radford: Henry Fowler

had joined the Midland Company on June 18, 1900 at a salary of £350

per annum in the position of Gas Engineer & Chief of the Testing Department,

from a similar position on the Lancashire and Yorkshire Railway at Horwich.

He was to be in just the right place at the right time and reap the full

fruits of the clash of personalities soon to develop between Deeley and Paget.

Fowler became Assistant Works Manager on November 1, 1905 in succession to

Paget. In 1905 he became Assistant Works Manager at Derby, and Works Manager

in 1907. In 1907 he was sent to North America to study work management. Two

years later he succeeded Deeley as CME. During World War 1 he was seconded

to the Ministry of Munitions, being Director of Production from 1915 to 1917

and then Assistant Director General of Aircraft Production. He was knighted

in 1918 for his war work.

In 1923 he became Deputy CME of the LMS and Mechanical Engineer, Derby,

succeeding Hughes as CME in October 1925. Although

notable progress was made in locomotive design under Fowler with the introduction

of the Royal Scot 4-6-0, the 2-6-4T and the 0-8-0, he failed to exercise

the technical lead and the strict control needed to overcome traditional

hostilities and to fuse the CME's department into a unified team.

Cox is especially critical of this period.

Fowler had a keen interest in research, particularly in metallurgy.

Under his influence the LMS sponsored a major investigation into the behaviour

of copper in fireboxes, and he had a reputation for being expert on aspects

of boiler materials and design. This interest in research was eventually

the means whereby he was removed from the post of CME without openly being

down-graded. In 1930 he was given a new post of Assistant to the Vice-President

for Works (Research and Development). In this post he pursued his research

interests for several years to the Company's benefit, and was responsible

for laying the foundations of the LMS Research Depart ment, which in turn

formed the basis of the British Railways research organisation. Fowler was

also interested in training, and maintained close contact with premium

apprentices and pupils for whom he was nominally responsible.

C.S. Lake noted that Sir Henry had told him that "he

had no enemy but the clock"..

Fowler retired in 1933 and died on 16 October 1938.

Carpenter, George W. biography Oxford

Dictionay of National Biography

Hamilton Ellis (The Midland

Railway) adds something to the strange relationship between Deeley,

Paget and Fowler: On January 1, 1904, Deeley became locomotive

superintendent, Paget was made works manager, and Fowler assistant works

manager. In spite of their work together,

Deeley and

Paget were an ill-assorted pair, though both

excellent men. To make matters worse, while Deeley was Paget's chief, Paget

was a son of Sir Ernest Paget, Bart., chairman of the Midland company, and

had wonderful ideas of his own which he intended to put into practice at

his earliest convenience. Already people wondered, without speaking, which

was really the Sultan and which the Grand Vizier. the background still was

Henry Fowler, the Lord in Waiting.

Dow's anecdote is worth

adding: At the time corridor tenders for the London-Edinburgh non-stop runs

were being considered one of Sir Nigel's daughters found her father one evening

on all fours in the family dining-room, squeezing his great bulk through

the narrow space formed between a wall and a row of chairs, set side by side.

To his daughter's astonished exclamation, 'What on earth are you doing, father?'

came the reply, 'If I can get through this, my biggest engineman can' Curiously

enough, there was a parallel incident in the career of the late Sir Henry

Fowler, the distinguished C.M.E of the old Midland, and of the L.M.S from

1928 to 1931, who was in the habit of cycling round Derby Works to

save time. On entering his office one day his assistant, H.G. Ivatt—son

of H.A. and later C.M.E of the L.M.S and now of the London Midland

Region—discovered Sir Henry on the floor endeavouring to get himself

through the round back of his office chair. When Ivatt expressed his surprise

Sir Henry explained that he wanted to find out whether or not he could get

through a certain type of locomotive firehole which happened to be the same

size as the hole in the back of his chair!

Radford tells a similar tale: So far as his employment is concerned,

he was extremely particular about boilers and fireboxes, being happy if he

could put on a boiler suit and tinker about. He was easily irritated, but

this did not last for long, and his usual reply when faced as he was on one

occasion by an estimate of six months for a new cylinder pattern was "I want

it in three". And that was the end of the discussion. His tours of the Derby

Works, while the manager there, were usually made by bicycle, he being

easily recognisable in his strawyard hat. He would ride around the Shops

inside and out and if he chanced upon someone committing a misdemeanour he

would remonstrate with him and then instruct the offender to "clock off"

and come back on the morrow, punishment indeed in those days of small wages

!

Rudgard (Presidential address Instn Loco. Engrs) stated "On the former

Midland Railway, with which I was particularly associated, a tribute is due

to the memory of Sir Henry Fowler. His collaboration with Cecil Paget,

and their understanding of the running shed angle, helped to produce a school

of design which was pre-eminent amongst all the railways forming the London

Midland and Scottish in 1923 for reliability and low repair costs, and which,

continuing under the LMS, lent itself admirably to the introduction of

developments in motive power practice and organisation; Sir William Stanier

carried on the good work".

Westwood considered

that Henry Fowler was an engineer of all-round ability with (according

to Westwood) no great talent in any direction. During his terms of office

new designs were built but these could rarely be called his own designs and

in some cases were introduced without his genuine approval. As a young man

he was involved in the early years of automobile engineering, but ... after

he became Chief Mechanical Engineer, Midland locomotive design seemed to

stagnate, but this was largely due to the civil engineering department's

aversion to larger locomotives; double-heading was preferred to track renewal.

Fowler did, however, build his solitary 0-10-0 for banking on the Lickey

Incline. After the Railway Amalgamation Fowler became assistant to the chief

mechanical engineer of the new LMSR (Hughes) until the latter retired. As

chief mechanical engineer in succession to Hughes, he allowed a kind of

'Derby imperialism', foisting Midland practice and design on to the

constituent parts of the LMSR. This was resented, and also meant that the

Midland 'small engine' policy infected the whole LMSR, Britain's largest

railway. However, it was one way of promoting standardization, and Midland

locomotives were very robust and cheap in construction and repair. Fowler's

proposed 4-6-2 compound, designed to provide the LMSR with a locomotive large

enough for its needs, was never built. The superintendent of motive power

(J. Anderson) appears to have been the most potent

source of opposition to Fowler's proposal; in the end, the LMSR., with scant

reference to Fowler, ordered the Royal Scot 4-6-0 from the North British

Locomotive Company instead of accepting Fowler's proposed 4-6-2. The introduction

of Garratt locomotives also seems to have been more the work of Anderson

than of Fowler. Among new designs in the Midland tradition of this period

were 2-6-2 and 2-6-4 tank locomotives, the last being the most successful

of the Fowler designs. His 0-8-0 was a relative failure, and his proposed

2-8-2 was never built. The peak of Fowler's career was probably 1914-18,

when he proved an excellent organizer of munitions production (for which

he received a knighthood). See: B. Haresnape, Fowler Locomotives

(1972).

Summary

From examination of what Sir Henry actually reported it is obvious

that Fowler has been grossly maligned by history and by E.S. Cox and Hamilton

Ellis (journalist and painter). Certainly, the birth of the LMS was one of

the most disastrous corporate events of the twentieth century. In retrospect

it was absurd to attempt to merge the LNWR and the Midland Railway.

Jenkins (footnotes objects to

this statement, but my KPJ view tends to have hardened with the years and

should be cast into print) It would have been like bringing the Great Western

into common ownership with either of these giants. The LNER worked because

the North Eastern was able to retain sufficient status through its contribution

to the new company of the brilliant General Manager, Wedgewood, and this

enabled Gresley to achieve brilliance. The Southern only worked once it became

a greater South Western (the Lord Nelson was a partial failure or

success).

A structure which would have tolerated autonomy to remain at both

Crewe and Derby might have worked and such a system was briefly contemplated

by the LNER. It is probable that both Hughes' and Fowler's reputations might

have remained unsullied in such a situation. Unfortunately, the Fowler Pacific

was intended for the WCML, and it might have been almost as good as Stanier's

earlier attempts: it would certainly have had a less troublesome boiler and

left on his own Fowler would have gleaned much from Gresley. The negative

contribution of Anderson requires further research

One gets the impression that Fowler was an amiable man with a great

interest in people, and although (like Collett) he appears to have been less

interested in locomotive design, although more so than has been given credit)

he was a considerable engineer with interests in metallurgy, a vital element

in locomotive design, and in boilers, and it is tragic that

Fury (the high-pressure locomotive

should have met with disaster due to metallurgical failure of one of

its tubes. The paper on superheating must have been comparable with Gresley's

one on high pressure boilers, and this emphasises that Fowler has been badly

treated by commentators. His comments on George Stephenson are highly perceptive

and contrast sharply with some of the rubbish written by intellectual minnows.

Fowler was clearly a brilliant scientific engineer and he must have been

extremely well-equipped to assess George Stephenson's extraordinary genius.

He must certainly have been a most likeable man:

Marjorie Bulleid, Ivatt's daughter,

wrote that "The Fowlers were always very kind on Railway Congress

meetings".

Superheating

The following is taken from Cox's Speaking of steam which quotes

from Fowler's magnus opus: "From the very dawn of locomotive history

the possibility of superheating was being thought about. . . R. Trevethick

was the first to apply the system to locomotive engines, and in 1828 he wrote

that he was building a small locomotive boiler in which he proposed to heat

the steam in small iron tubes as it passed from the boiler to the cylinder.

From his patent No 6308 of 1832 it is evident that it was his intention

that these tubes should be placed over the fire itself. . . In 1839, Messrs

Hawthorn patented a smokebox superheater, while between 1850 and 1870 numerous

devices were brought out including examples of practically all the types

which have been experimented with in recent years. .. . It seems to have

been recognised early that in order to obtain the best results, a fair degree

of superheat was necessary, but in practice it was found that this led to

trouble both with the valves and the packing. . . . After 1870 use of superheated

steam was gradually abandoned and its extensive practical use is a matter

of very recent date."

Fowler went on to state that Dr Wilhelm Schmidt

began in 1895 to apply to locomotives the knowledge he had gained in the

use of superheated steam for other purposes, and in 1897 he produced his

first practical design. His previous experience had indicated that the best

results were to be looked for in the use of a high degree of superheat, and

his successful redevelopment of the process was greatly indebted to the practical

trials carried out by Herr Robert Garbe in charge of motive power on the

Prussian State Railways. The Schmidt superheater passed through two preliminary

design phases before it arrived at the form in which it is known all over

the world today. Originally a nest of superheater elements was situated in

a vast central tube 1ft 8in diameter connecting firebox to smokebox. Secondly,

a superheater entirely within the smokebox was devised, the temperature of

the hot gases as they emerged from the small tubes being supplemented by

what came out of an additional single large empty tube of 1ft diameter.

In both these cases the problem of keeping these large tubes tight in the

tubeplates proved insurmountable and the final manifestation was to divide

the saturated steam in a header, and pass it down multiple elements placed

inside a number of flue tubes of approximately 5in diameter, the steam thus

superheated returning to separate compartments in the header, whence it was

conveyed by suitable steampipes to the cylinders–the ultimate and basic

Schmidt lay out.

This layout proved so wonderfully flexible in permitting by suitable

proportions any desired degree of superheat, and relative volume and velocity

of hot gases issuing into the smokeboxes and was so simple and cheap and

reliable, that in spite of many intermediate variations by engineers who

thought they knew better it remained practically unchanged until the last

days of steam. Not so was the ancillary gadgetry which was at first thought

necessary for its successful use, nor the designs of valves and piston packing

which were developed to cope with the high steam temperatures attained. Although

many attempts were made, some of them partially successful, to retain slide

valves, use of piston valves became general, and since these bore the brunt

of the highest temperatures conveyed by the incoming steam, their design

was critical. Fowler describes the history of the inception of the Schmidt

wide piston valve ring which was for the first two decades and more in almost

universal use:

Portraits

Cox: Locomotive panorama v.1 fp.

4: shown with L&YR officers and with Gresley,

O'Brien, Hughes, and Aspinall at a formal function in 1912.

Group photograph at Swiss Locomotive Works, Winterthur on 2 June 1930.

J. Instn Loco. Engrs., 1930,

20, Plate (between pp 466-7)

Bibliography (about Fowler)

Appointment as CME Midland Railway. Loco. Rly Carr. Wagon Rev.,

1910, 16, 5.

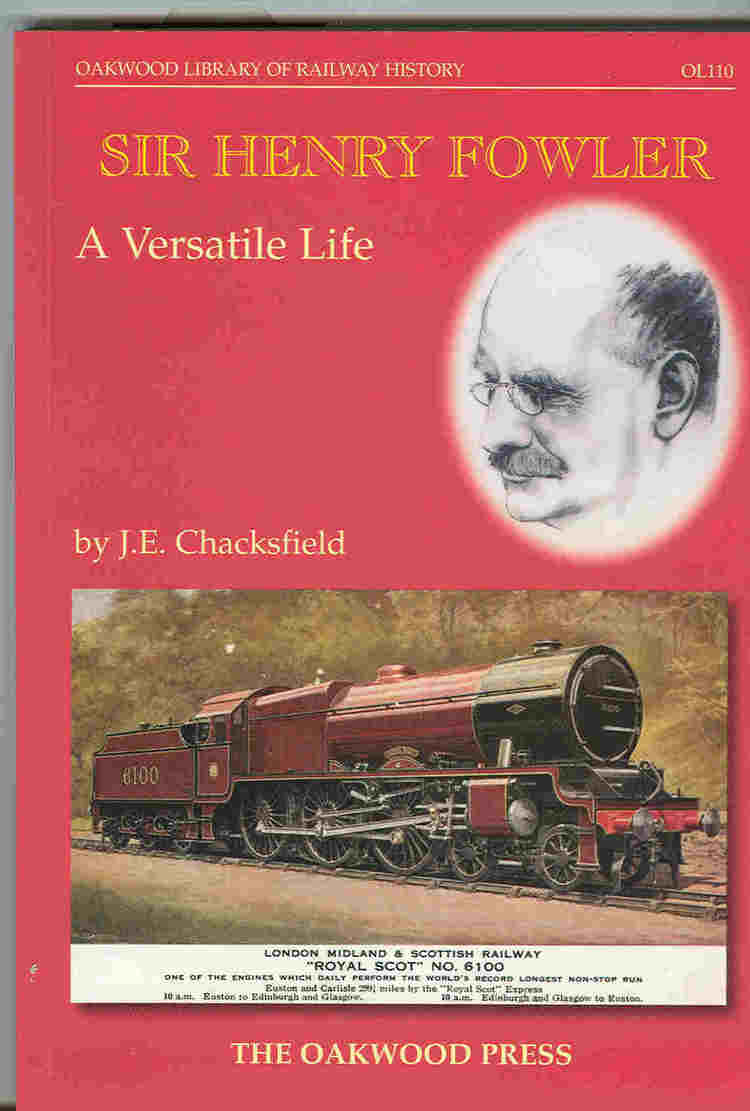

Chacksfield, J.E. Sir Henry

Fowler: a versatile life. Usk(Mon): Oakwood

Slightly disappointing in that too little attention is paid to his

considerable technical expertise.

Cox, E.S. A modern locomotive history:

ten years' development on the L.M.S.- 1923 to 1932. J.Instn Loco.

Engrs, 1946, 36, 100-41. Disc.: 141-70; 275-6. (Paper No. 457).

Glover, F.G. British locomotive design, 1923-1947. Part 3. The work

of Henry Fowler and the advent of the Stanier regime on the L.M.S.R., Rly

Mag., 1965, 111, 10-13.5 illus.

A broad introduction.

Lake, C.S. Some C.M.E.s I have known. ll — Sir

Henry Fowler. Rly Mag., 1942, 88, 287-90 + plate f.p. 257.

8 illus. (incl. port.)

Personal reminiscences.

The LATE Sir Henry Fowler. Rly Gaz., 1938, 69, 674.

Editorial.

The LATE Sir Henry Fowler, K.B.E.. Rly Gaz., 1938, 69, 685-6.

illus. (port.)

MEMOIRS: Sir Henry Fowler, K.B.E., L.L.D., B.Sc.. Proc. Instn mech.

Engrs, 1938, 140, 600-1.

NEW "Royal Scot" locomotive, L.M.S. Ry..

Loco. Rly Carr. Wagon Rev., 1930,

36, 363.

The naming ceremony of No.6169 The Boy Scout performed by Sir

Henry Fowler, acting in the capacity of a former Scout District Commissioner.

Ironically the same page contains the LMS Board decision to move Sir Henry

into research; and ease Lemon into his place

Nock, O.S. Steam locomotive : the unfinished story of steam locomotives

and steam locomotive men on the railways of Great Britain. London, Allen

& Unwin, 1957. 233 p. + 32 plates. 106 illus. (incl.. 29 ports.)

Includes a biographical portrait of Fowler.

OBITUARY, Sir Henry Fowler, K.B.E.. Loco. Rly Carr. Wagon Rev., 1938,

44, 336.

The RAILWAY portrait gallery : Sir Henry Fowler, K.B.E.. Rly Mag.,

1925, 57, 237. illus. (port.)

The RAILWAY portrait gallery : Sir Henry Fowler, K.B.E.. Rly Mag.,

1931, 68, 36. illus. (port.)

Diesel locomotives

Alcock. John F. in Discussion on Doherty, J.M. Evolution of the internal

combustion locomotive. J. Instn Loco.

Engrs, 1946, 56, 235-68. Disc.: 271 et seq. (Paper No.

558)

noted that around 1932 Sir Henry Fowler went to America to see the

progress made with diesel locomotives there, and on his return decided to

carry out what must then have appeared to be large scale experiments. Very

satisfactory and encouraqing results were already being obtained with two

trial diesel locomotives, the first being the Hunslet 150 h.p. and the second

a 250 h.p. Armstrong Whitworth diesel-electric type. Then there were the

early Avonside diesel locomotives. Both these locomotives which had previously

been on loan were purchased by the LMS and Sir Henry obtained a grant from

his board of £30,000 tor experimenting with various types of diesel

locomotive. At the time it seemed a tremendous sum and it certainly bought

something like ten shunting locomotives, of about the 30-ton mark. It was

from these early experiments which lasted several years, that the LMS eventually

standardised on the 50-ton 450 h.p. diesel-electric locomotive for shunting

purposes, but it has always been his view and still is that the only reason

the diesel-electric was selected was because in those early experiments all

the diesel-mechanical units were from 150 to 200 h.p. only, while the

diesel-electric units were from 250 to 300 h.p. On shunting work and particularly

on hump shunting and fly shunting on which all the locomotives were tried,

the larger, heavier and more powerful locomotives were obviously bound to

be the more useful in moving the traffic. He was quite sure that had it been

the other way round and had the diesel-mechanical units been the more powerful

and heavier ones, then they would have prevailed just as easily. As it was,

the 200 h.p. diesel-mechanical unit was fully proved at that time and ever

since has more than justified itself, and it is indeed strange that in the

last 25 years the wheel has turned a full circle and British Railways are

now using large numbers of 200 h.p. 30-ton diesel-mechanical

locomotives.

Updated: 23-01-2015

Return to Home page